Spicy lunch meat can and preparation method thereof

A technology of canned luncheon meat and spicy, which is applied in the fields of canned spicy luncheon meat and its preparation, and canned meat food. The effect of thaw time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

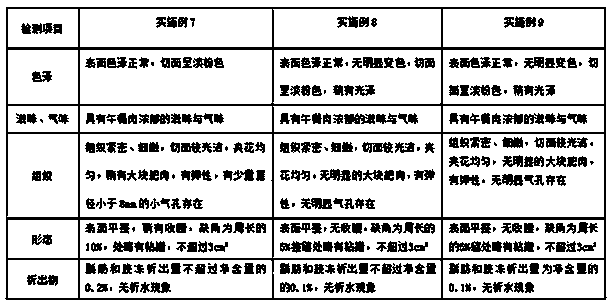

Examples

Embodiment 1

[0027] A canned spicy luncheon meat, comprising the following raw materials by weight: 55 parts of pork, 30 parts of chicken, 6 parts of corn starch, 1 part of edible salt, 0.5 part of white sugar, 0.08 part of I+G, 0.08 part of MSG, tripolymer Sodium phosphate 0.005 part, sodium pyrophosphate 0.005 part, xanthan gum 0.4 part, konjac gum 0.2 part, dried chili powder 0.1 part, red date powder 0.5 part, D-isoascorbate sodium 0.04 part, spice 0.03 part, salt water 0.5 part The spice is a mixture of jade fruit and pepper, and the mixing ratio is 1:2.

Embodiment 2

[0029] A canned spicy luncheon meat, including the following raw materials by weight: 70 parts of pork, 15 parts of chicken, 10 parts of corn starch, 1.5 parts of edible salt, 1.5 parts of white sugar, 0.04 parts of I+G, 0.2 parts of MSG, tripolymer 0.01 part of sodium phosphate, 0.005 part of sodium pyrophosphate, 0.3 part of xanthan gum, 0.3 part of konjac gum, 0.4 part of bright red pepper, 1.5 part of red date powder, 0.06 part of sodium D-isoascorbate, 0.06 part of spice, 5% ice 3 parts of brine; the spice is a mixture of yuguo and pepper, and the mixing ratio is 1:4.

[0030] Among them, the fineness of dried chili powder and red date powder are both 40 mesh.

Embodiment 3

[0032] A canned spicy luncheon meat, comprising the following raw materials in parts by weight: 65 parts of pork, 25 parts of chicken, 8 parts of corn starch, 1.2 parts of edible salt, 1.2 parts of white sugar, 0.06 parts of I+G, 0.16 parts of MSG, tripolymer 0.008 parts of sodium phosphate, 0.01 parts of sodium pyrophosphate, 0.36 parts of xanthan gum, 0.5 parts of konjac gum, 0.3 parts of bright red pepper, 1 part of red date powder, 0.045 parts of sodium D-isoascorbate, 0.04 parts of spices, 1 part of salt water; The spice is a mixture of yuguo and pepper, and the mixing ratio is 1:3.

[0033] Among them, the fineness of dried chili powder and red date powder are both 60 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com