Brown lactic acid bacteria drink and preparation method thereof

A lactic acid bacteria drink and the technology of lactic acid bacteria are applied in the field of brown lactic acid bacteria drink and its preparation, and can solve the problems of obesity and high sugar content of consumers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

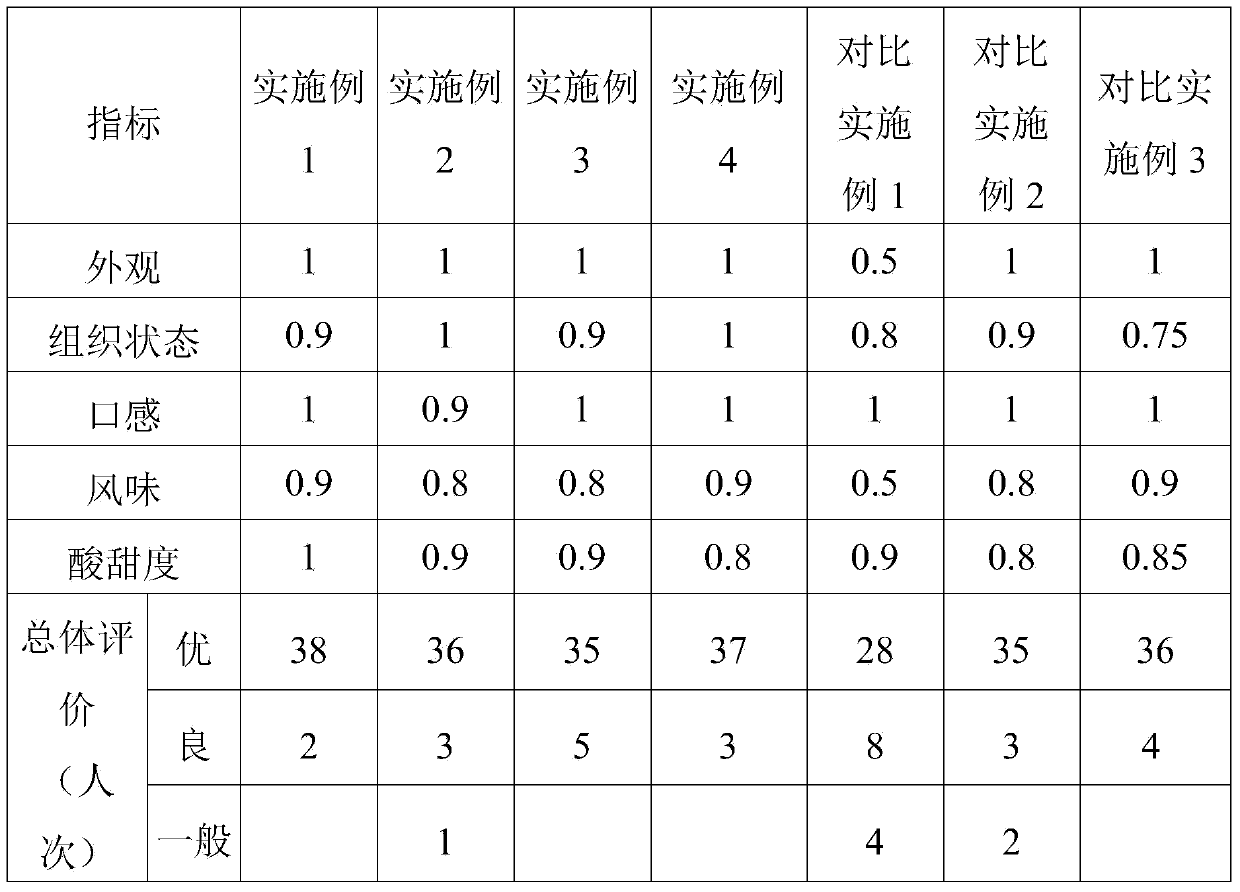

Embodiment 1

[0052] In this embodiment, the skim milk powder includes: 0.8% fat, 32% protein, and 56% lactose, and the percentages are the mass percentages of the skim milk powder.

[0053] Preparation:

[0054] (1) Mix 13% skimmed milk powder with 86.92% water, add 0.08% lactase for recovery, circulate and stir at 20°C for 25min, cool to 10°C, and stand for 6h to obtain slurry A;

[0055] (2) Raise the temperature of slurry A to 95°C, keep it warm for 1.5h, and after cooling to 37°C, add Lactobacillus paracasei (addition amount 4×10 6 cfu / mL slurry A) and Lactobacillus helveticus (addition amount 1×10 6 cfu / mL slurry A), fermented at 37°C for 48 hours, turned over, homogenized, cooled to 16°C, homogenized at a pressure of 18 MPa, and at a temperature of 37°C to obtain a fermented milk base;

[0056] (3) Dissolve 12% white sugar, 0.2% pectin, and 0.02% monoglyceride in 67.71% water at 65°C, sterilize at 95°C for 5 minutes, cool to 30°C, and mix with 20% fermented milk base Mix the mater...

Embodiment 2

[0058] In this embodiment, the skim milk powder includes: 0.5% fat, 33% protein, and 52% lactose, and the percentages are the mass percentages of the skim milk powder.

[0059] Preparation:

[0060] (1) Mix 14% skimmed milk powder with 85.95% water, add 0.05% lactase for recovery, stir at 40°C for 40 minutes, cool to 4°C, and stand for 5 hours to obtain slurry A;

[0061] (2) Raise the temperature of slurry A to 90°C, keep it warm for 2.5h, and after cooling to 35°C, add Lactobacillus paracasei (addition amount 1×10 6 cfu / mL slurry A) and Streptococcus thermophilus (addition amount 1×10 6 cfu / mL slurry A), fermented at 35°C for 60 hours, turned over, homogenized, cooled to 22°C, homogenized at a pressure of 18 MPa, and at a temperature of 37°C to obtain a fermented milk base;

[0062] (3) Mix 9% white sugar, 0.3% soybean polysaccharide, and 0.05% diglyceride in 65.52% water at 70°C, stir evenly, cool to 15°C, mix evenly with 25% fermented milk base material, add 0.08% malic...

Embodiment 3

[0064] In this embodiment, the skim milk powder includes: 0.6% fat, 32% protein, and 55% lactose, and the percentages are the mass percentages of the skim milk powder.

[0065] Preparation:

[0066] (1) Mix 8% skim milk powder with 91.94% water, add 0.06% lactase for recovery, stir at 40°C for 40 minutes, stop stirring, and stand at 40°C for 1 hour to obtain slurry A;

[0067] (2) Raise the temperature of slurry A to 137°C, keep it warm for 15min, and after cooling to 37°C, add Lactobacillus casei (Lactobacillus casei) into slurry A (addition amount 2×10 6 cfu / mL slurry A) and Lactococcus lactis subsp.Lactis, Lactococcus lactis subsp.Cremoris, Lactococcus lactis (addition amount 6×10 6 cfu / mL slurry A), ferment at 37°C for 36 hours, turn over the tank, homogenize, cool to 22°C, homogenize at a pressure of 18 MPa, and at a temperature of 37°C to obtain a fermented milk base;

[0068] (3) 4.97% white sugar, 0.015% acesulfame potassium, 0.015% aspartame, 1% inulin, 0.35% sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com