Brewing method of low-alcohol-content dry blueberry wine

A low-alcohol, dry-type technology, applied in the preparation of alcoholic beverages, methods based on microorganisms, biochemical equipment and methods, etc., can solve the problems of difficult survival, high osmotic pressure of fruit epiphytic yeasts, etc., and achieve pleasant aroma People, appearance are excellent, the effect of increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Select 100kg of blueberry fruit with a sugar content of 8.5% and a total acid content of 0.9%. After crushing, add 1g / kg of pectin-cellulose-starch compound enzyme, 65g / kg of sucrose, 0.05% of ammonium sulfate, and 20mg / kg of sodium metabisulfite. kg, moved into the fermenter, the fermented mash volume is less than 80% of the tank volume; inoculated with 5% wine yeast AS2.316, fermented at 28°C, squeezed out the original wine after 8 days of fermentation; the original wine was moved into a new tank, the wine volume did not exceed 95%, Then add sodium metabisulfite 20mg / L, age for 90 days, and pour the cans 3 times in the middle; after the aging, it can be packed. The pectin-cellulose-starch compound enzyme is obtained by configuring pectinase, cellulase, and amylase in a ratio of 1:1-1.1:1-1.1, and its dosage is 0.1-2g / L. The temperature is 30-50°C, and the enzymatic hydrolysis time is 30-240min. Use after activation.

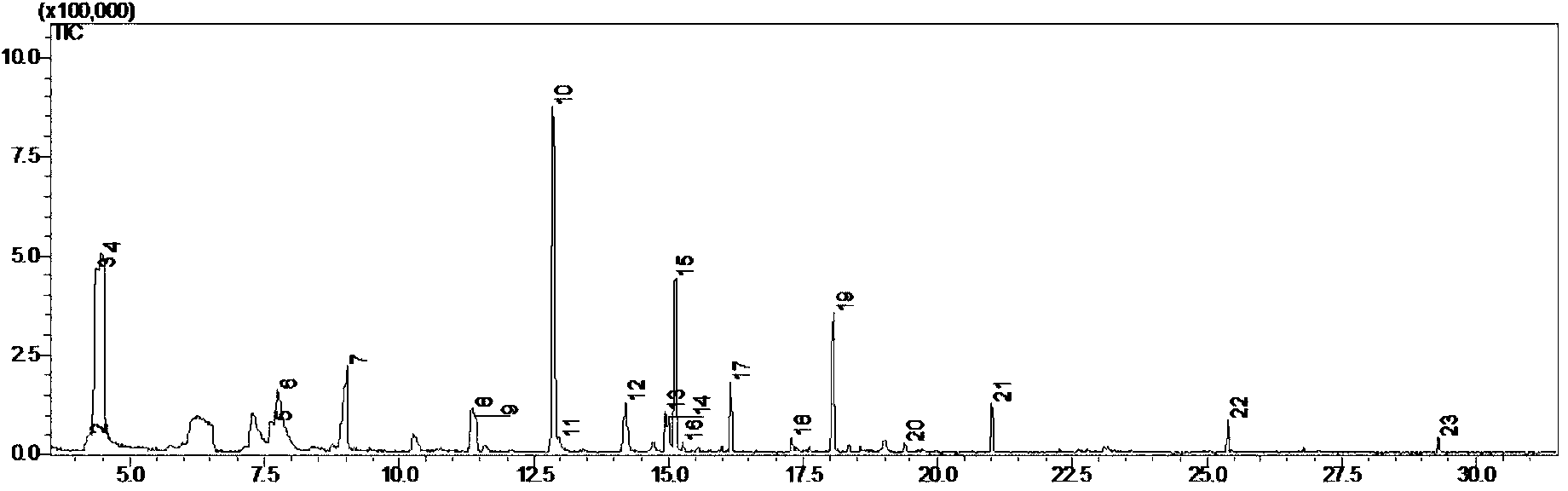

[0027] The alcohol content of the fermented blueb...

Embodiment 2

[0031] Select 100kg of blueberry fruit with a sugar content of 9.5% and a total acid content of 0.6%. After crushing, add 1g / kg of pectin-cellulose-starch compound enzyme, 45g / kg of sucrose, 0.05% of ammonium sulfate, and 20mg / kg of sodium metabisulfite. kg, moved into the fermenter, the fermented mash volume is less than 80% of the tank volume; inoculated with 4% Angel active dry yeast RA-4, fermented at 22°C, squeezed out the original wine after 8 days of fermentation; moved the original wine into a new tank, and the volume of the wine did not exceed 95%, then add sodium metabisulfite 20mg / L, age for 90 days, and pour the cans 3 times in the middle; after the aging, canned. The pectin-cellulose-starch compound enzyme is obtained by configuring pectinase, cellulase, and amylase in a ratio of 1:1-1.1:1-1.1, the dosage is 0.1-2g / L, and the enzymolysis temperature The temperature is 30-50°C, and the enzymatic hydrolysis time is 30-240min. Use after activation.

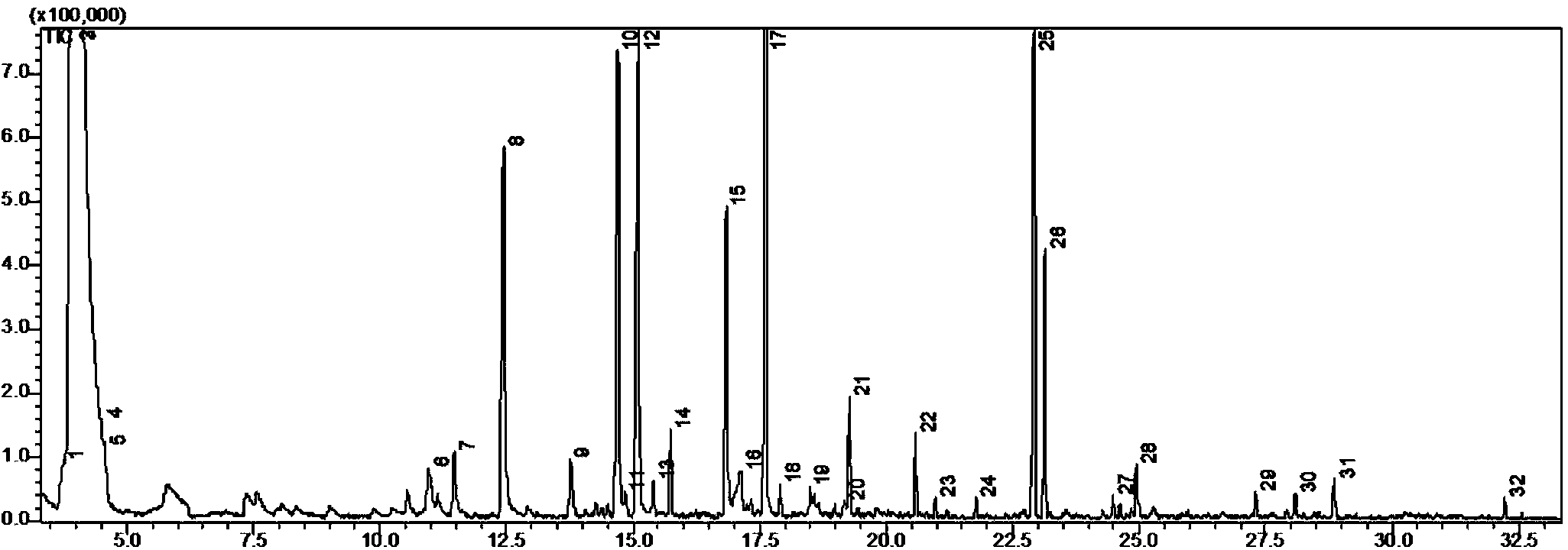

[0032] The alco...

Embodiment 3

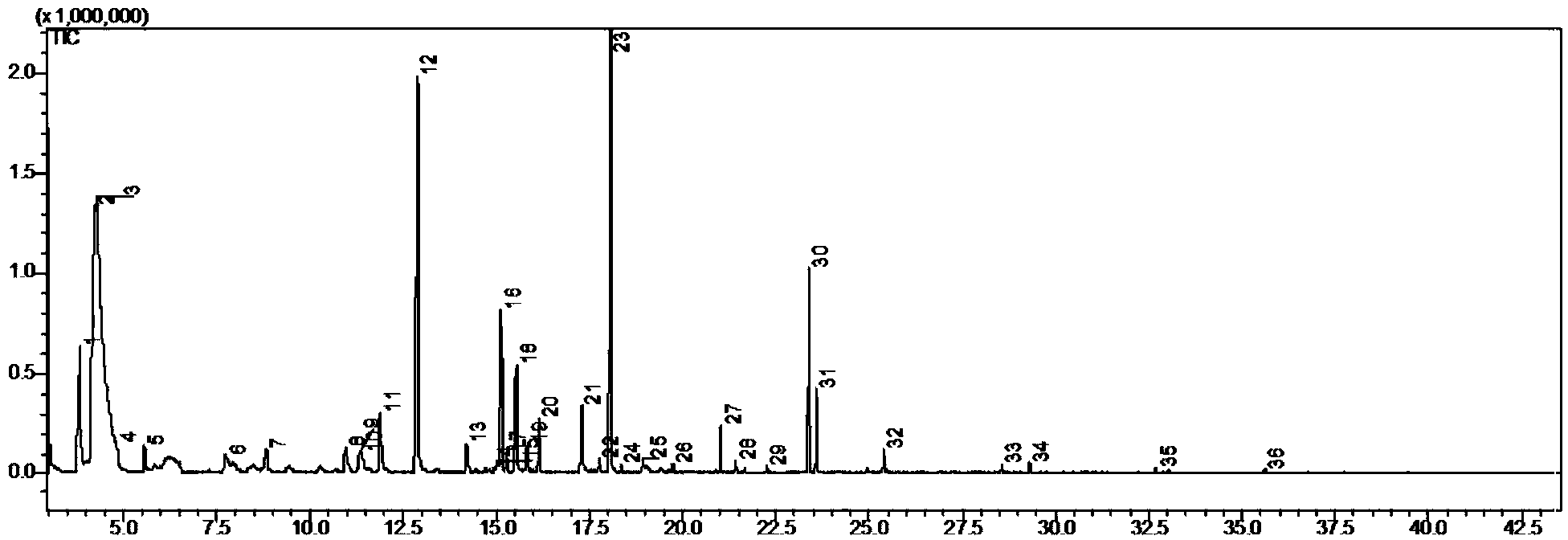

[0035] Select 100kg of blueberry fruit with a sugar content of 11.5% and a total acid content of 0.8%. After crushing, add 1g / kg of pectin-cellulose-starch compound enzyme for enzymolysis. The enzymatic hydrolysis temperature is 30°C and the enzymatic hydrolysis time is 120min. Squeeze the juice after enzymolysis, add 35g / kg of sucrose, 0.05% of ammonium sulfate, and 20mg / kg of sodium metabisulfite, move it into the fermenter, add skin dregs, the volume of fermented mash is less than 80% of the tank volume; inoculate 2% of YM liquid medium for pre-treatment Cultured blueberry fruit epiphytic yeast and 3% wine yeast AS2.316, fermented at 25°C, squeezed out the original wine after 8 days of fermentation; moved the original wine into a new tank, the wine volume did not exceed 95%, and then added sodium metabisulfite 20mg / L , aged for 90 days, poured 3 times in the middle; canned after aging. The pectin-cellulose-starch compound enzyme is obtained by configuring pectinase, cellula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com