Positive electrode composite material for lithium sulfur battery

A composite material, lithium-sulfur battery technology, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of high cost and poor cycle stability, and achieve the effect of easy operation, stable cycle performance and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

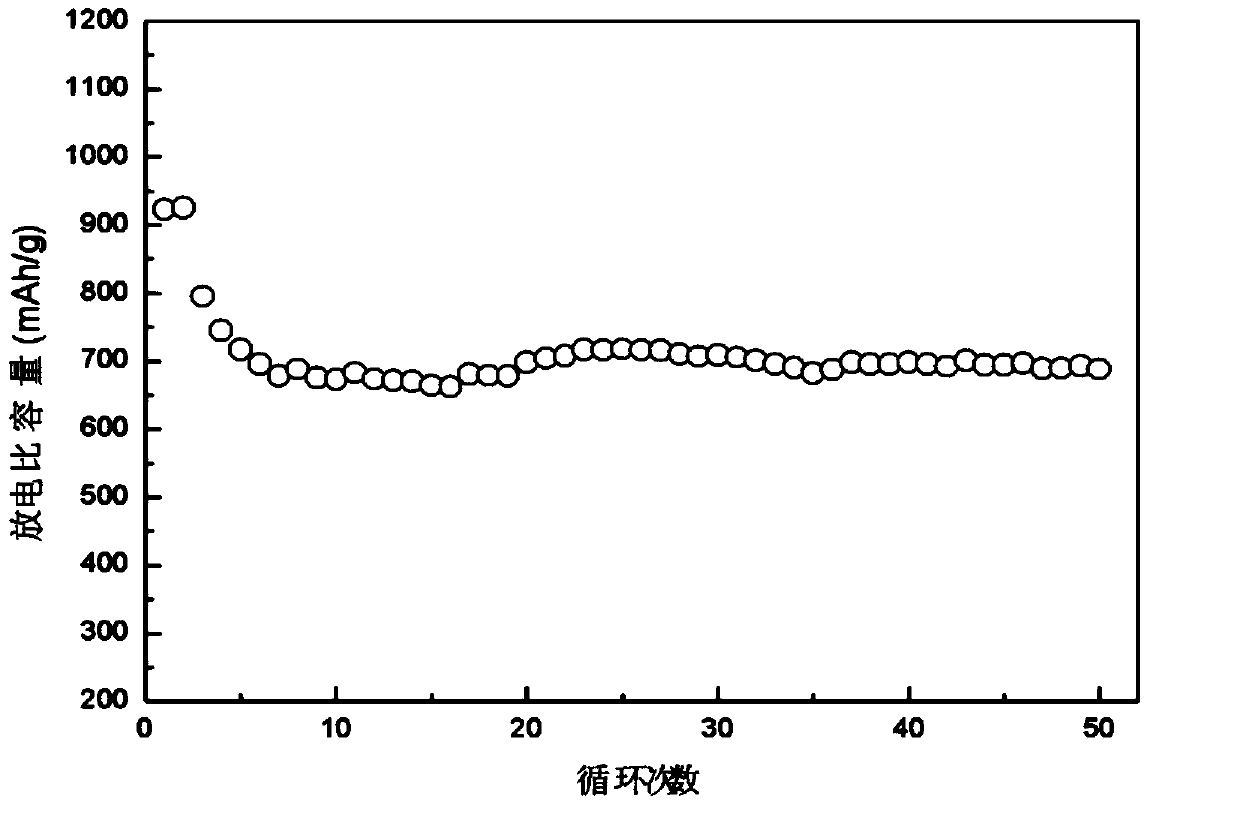

Embodiment 1

[0041] The positive electrode composite material for lithium-sulfur batteries in this embodiment includes the following components by weight: 2.0 g of activated clay and 2.5 g of sublimed sulfur (the mass ratio of activated clay to sublimed sulfur is 4:5).

[0042] The preparation method of the lithium-sulfur battery positive electrode composite material of the present embodiment comprises the following steps:

[0043]1) Pretreatment of matrix materials: take activated clay and place it in a vacuum drying oven, dry it at 60°C for 8 hours, take it out, and ball mill it for 5 hours at a ball-to-material ratio (volume ratio) of 1:1 and a speed of 400r / min to obtain activity Fine clay powder;

[0044] 2) Preparation of composite materials (high-temperature solid-phase method): Accurately weigh 2.0g of activated clay fine powder and 2.5g of sublimed sulfur obtained in step 1), mix and grind evenly, place in an atmosphere furnace, and treat at 155°C for 6 hours , that is, the activ...

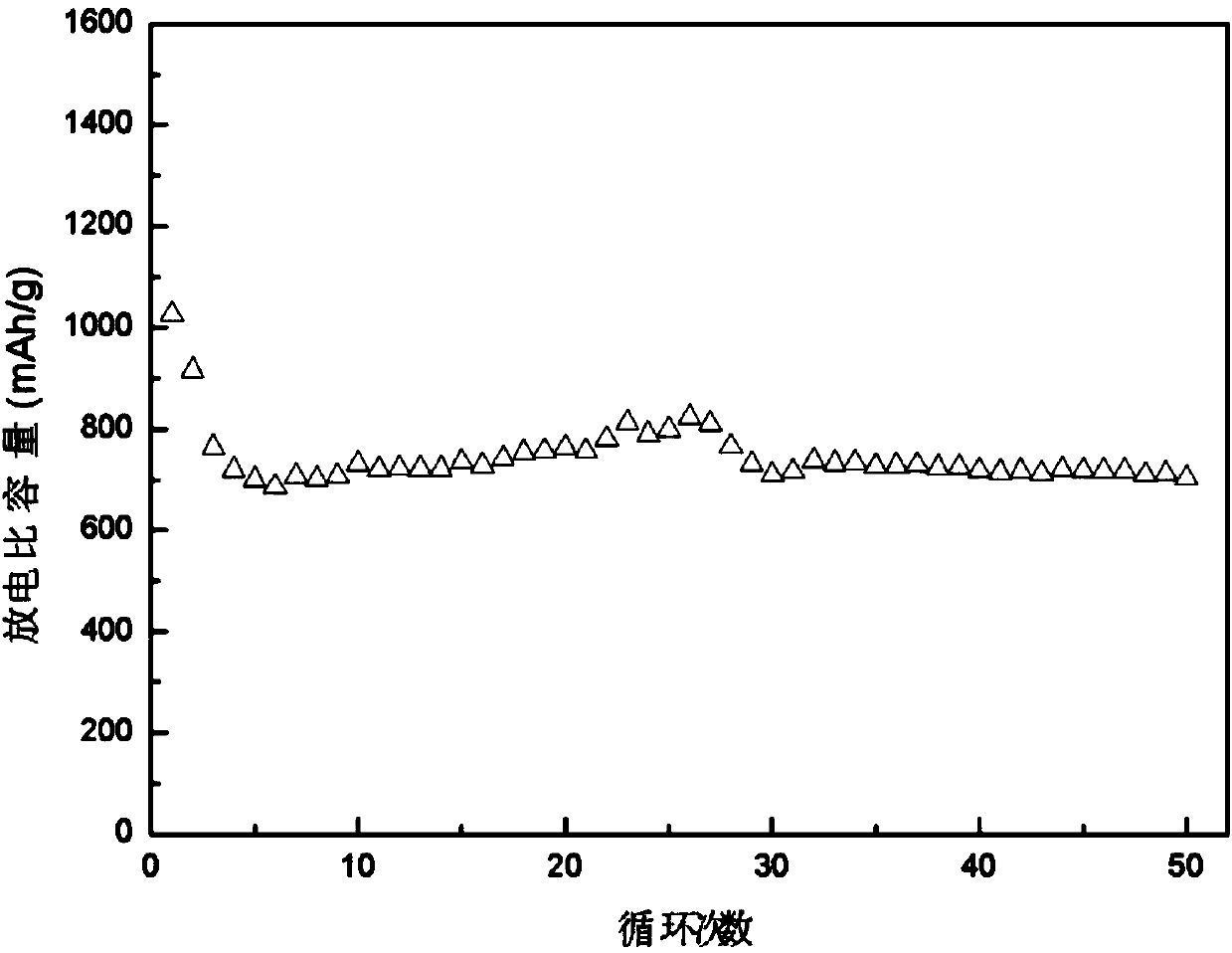

Embodiment 2

[0049] The positive electrode composite material for lithium-sulfur batteries in this embodiment includes the following components by weight: 4 g of lithium-based bentonite, and 3.0 g of sublimed sulfur (the mass ratio of lithium-based bentonite to sublimed sulfur is 4:3).

[0050] The preparation method of the lithium-sulfur battery positive electrode composite material of the present embodiment comprises the following steps:

[0051] 1) Pretreatment of matrix materials: take lithium-based bentonite and place it in a vacuum drying oven, dry it at 60°C for 8 hours, take it out, and ball mill it for 6 hours under the conditions of ball-to-material ratio (volume ratio) of 1:3 and rotational speed of 300r / min to obtain Lithium bentonite fine powder;

[0052] 2) Preparation of composite materials (mechanical ball milling method): Accurately weigh 4.0g of lithium-based bentonite fine powder and 3.0g of sublimated sulfur obtained in step 1) in a machine with a ball-to-material ratio...

Embodiment 3

[0056] The positive electrode composite material for lithium-sulfur batteries in this embodiment includes the following components by weight: 2.0 g of calcium-based bentonite and 3.0 g of sublimed sulfur (the mass ratio of calcium-based bentonite to sublimed sulfur is 4:6).

[0057] The preparation method of the lithium-sulfur battery positive electrode composite material of the present embodiment comprises the following steps:

[0058] 1) Pretreatment of matrix materials: take calcium-based bentonite and place it in a vacuum drying oven, dry it at 50°C for 10 hours, take it out, and ball mill it for 2.5 hours at a ball-to-material ratio (volume ratio) of 1:5 and a speed of 600r / min. Get calcium-based bentonite fine powder;

[0059] 2) Preparation of composite materials (liquid phase method): the specific operation process is as follows:

[0060] a. Dissolve 3.0g of sublimed sulfur in 12ml of toluene at 100°C to obtain elemental sulfur-toluene solution;

[0061] b. Accuratel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com