Integrated LED element with epitaxial structure and packaging substrate integrated and manufacturing method

An epitaxial structure, packaging substrate technology, applied in the direction of electrical components, semiconductor devices, electric solid devices, etc., to achieve high power density and reduced thermal resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] Therefore, an integrated LED element combined with an epitaxial structure and a packaging substrate of the present invention and its manufacturing method can effectively reduce the manufacturing process of LED elements, save materials, reduce costs, and effectively reduce the layer-by-layer heat conduction of LED elements. resistance, improve the characteristics of the LED element, and solve the problems of the prior art.

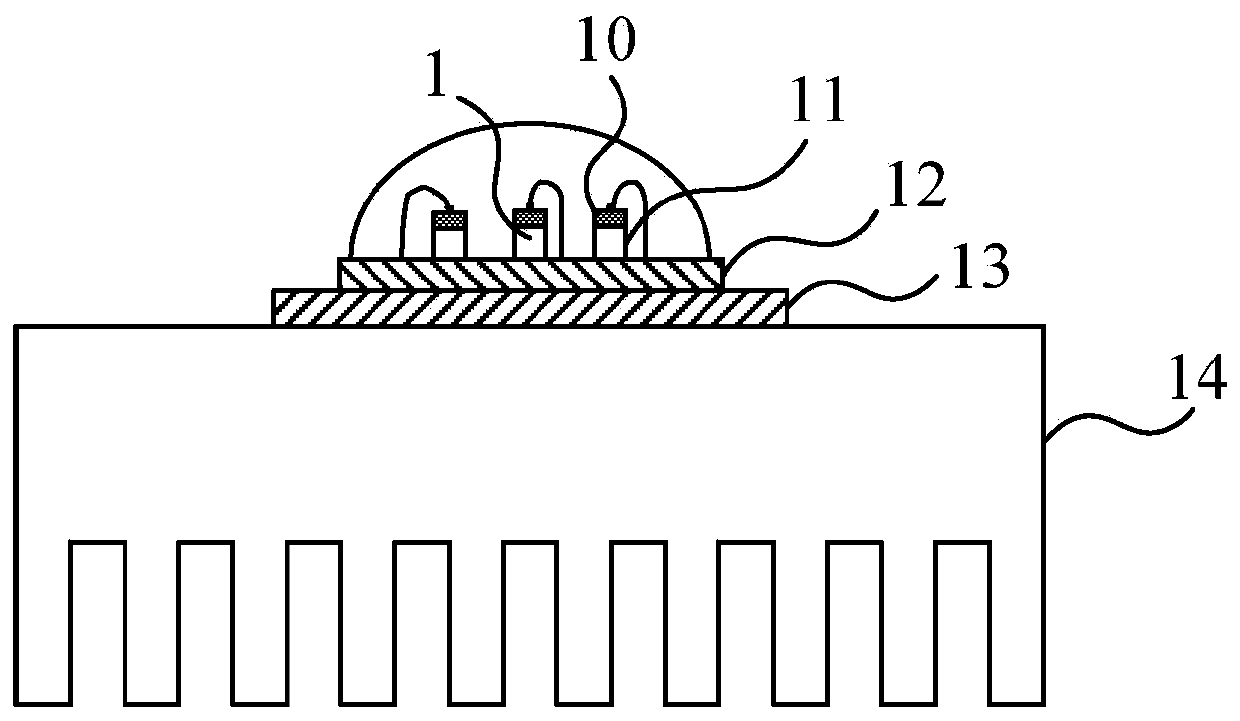

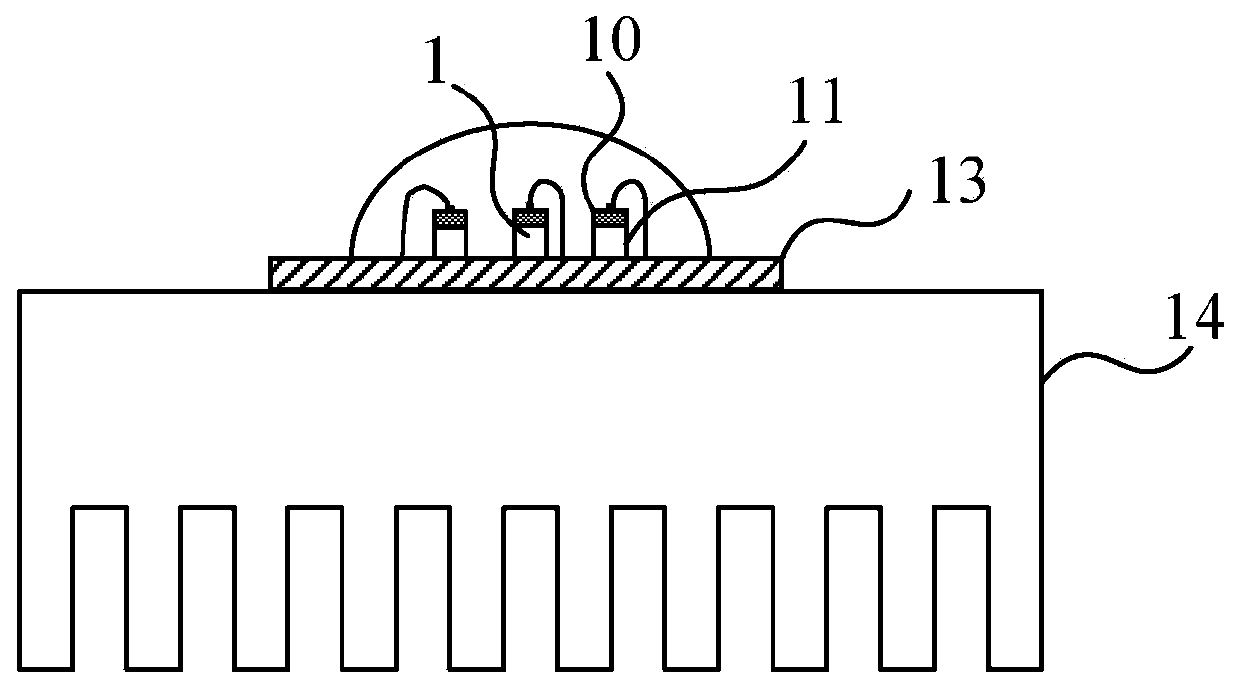

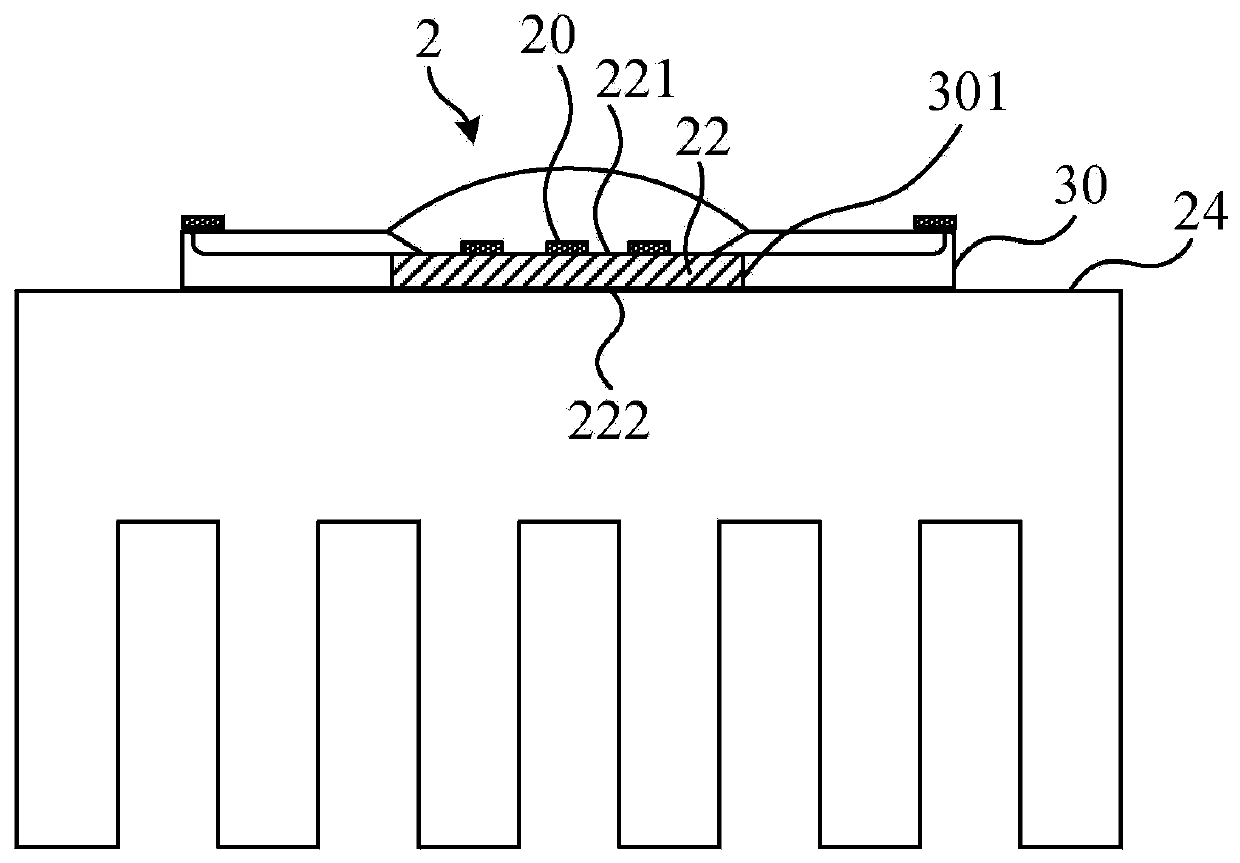

[0090] see Figure 2A and Figure 2B , Figure 2A as well as Figure 2B The structure schematic diagrams of the LED epitaxial structure, the LED package and its arrangement on the bare empty carrier and the LED heat dissipation and heat conduction elements shown in the integrated LED element of the present invention are respectively shown. According to a specific embodiment, the LED element 2 integrated with the epitaxial structure and the packaging substrate of the present invention can be embedded in a bare empty area 301 of a bare empty carrier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com