Rectangular butt-welded seam steel pipe for communication tower

A technology for butt welding seams and communication towers, which is applied in the field of communication towers, can solve the problems of high matching dimensional accuracy, complicated operation process, and high processing cost, and achieve the effects of low dimensional accuracy requirements, high overall strength, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

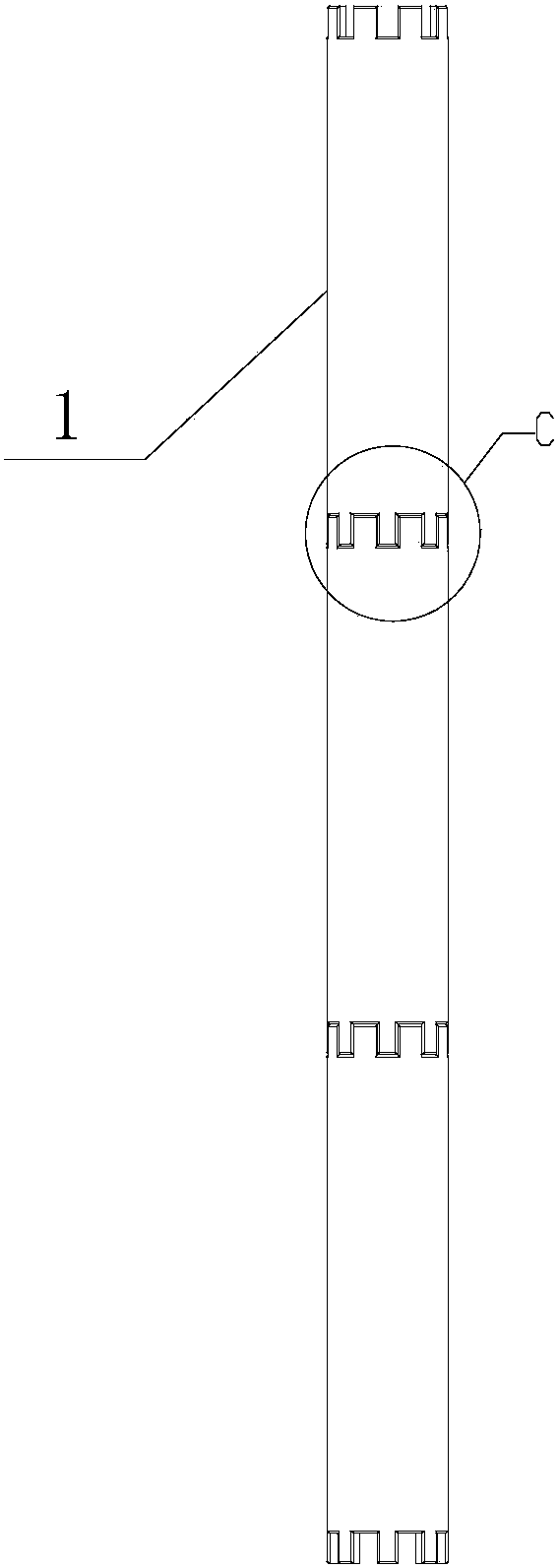

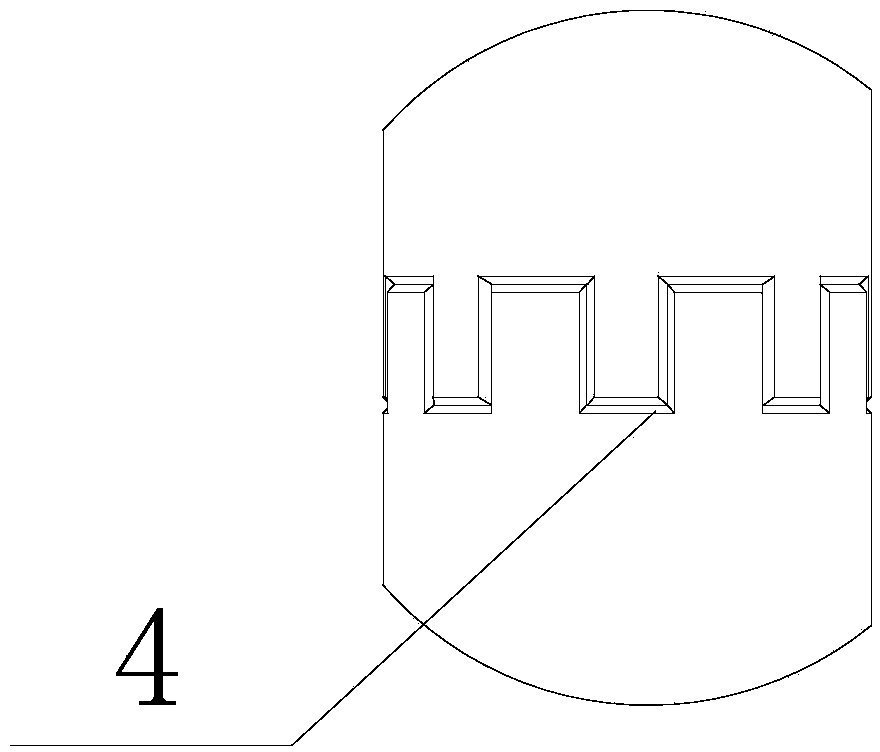

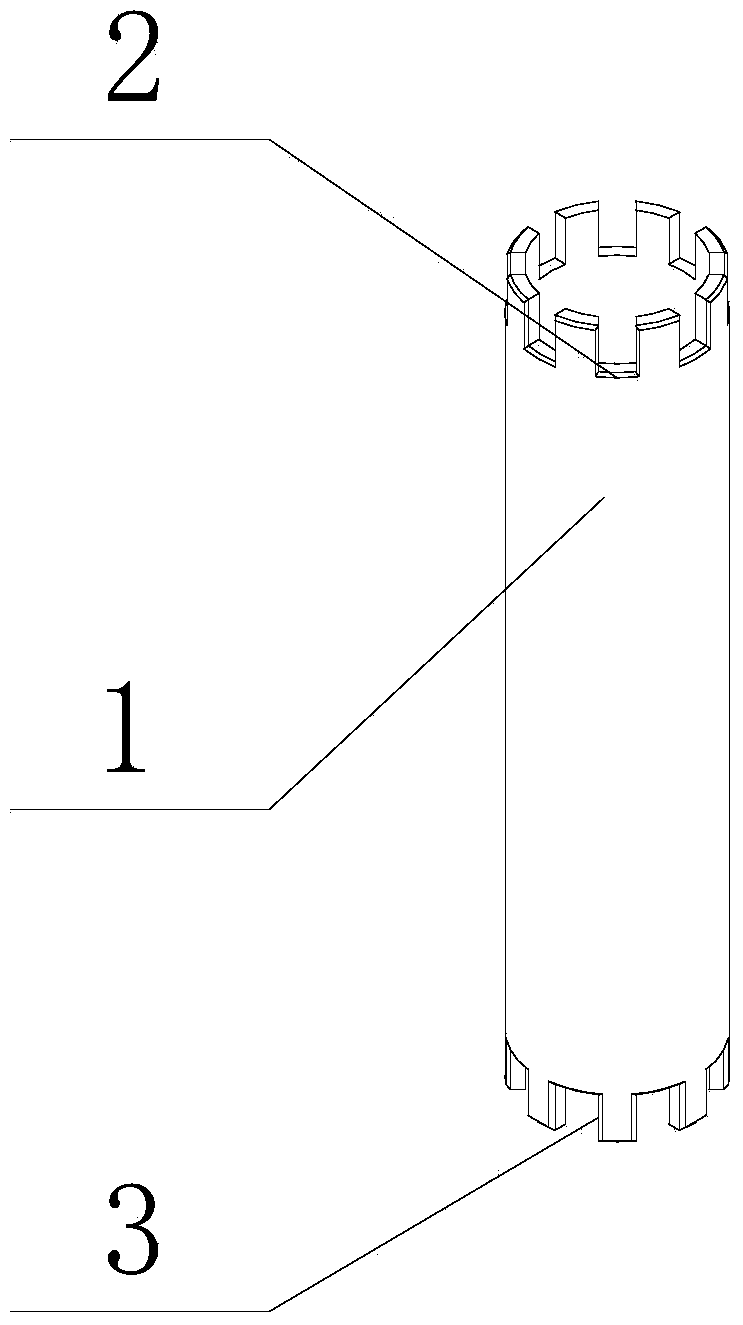

[0021] A rectangular butt welded steel pipe for communication towers provided in this embodiment includes three steel pipes 1, the steel pipes 1 are arranged in sequence along the axial direction, and the adjacent steel pipes 1 are welded at the butt joints, and one end of the steel pipes 1 is arranged along the axial direction. There is a rectangular groove 2, and the other end is provided with a rectangular boss 3, the number of the rectangular groove 2 and the rectangular boss 3 are equal and the number is eight, the number is set to eight, which is convenient for processing, easy to assemble and cooperate, and improves work efficiency , the rectangular groove 2 and the rectangular boss 3 are evenly distributed in the circumferential direction of the steel pipe 1, the rectangular boss 3 at the joint of any two adjacent steel pipes 1 can be inserted into the rectangular groove 2, the rectangular groove 2 and the rectangular boss 3 The dimensions are exactly the same, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com