Cantilever-type slidable anti-collision connection device for ship berthing platform

A technology for connecting devices and platforms, applied in shipping equipment, climate change adaptation, etc., can solve problems such as height difference, distance, relative rotation, damage of connectors, and damage to marine platforms that rarely consider anti-collision objects, so as to ensure convenience. and safety, reduce the possibility of impact damage, and ensure the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

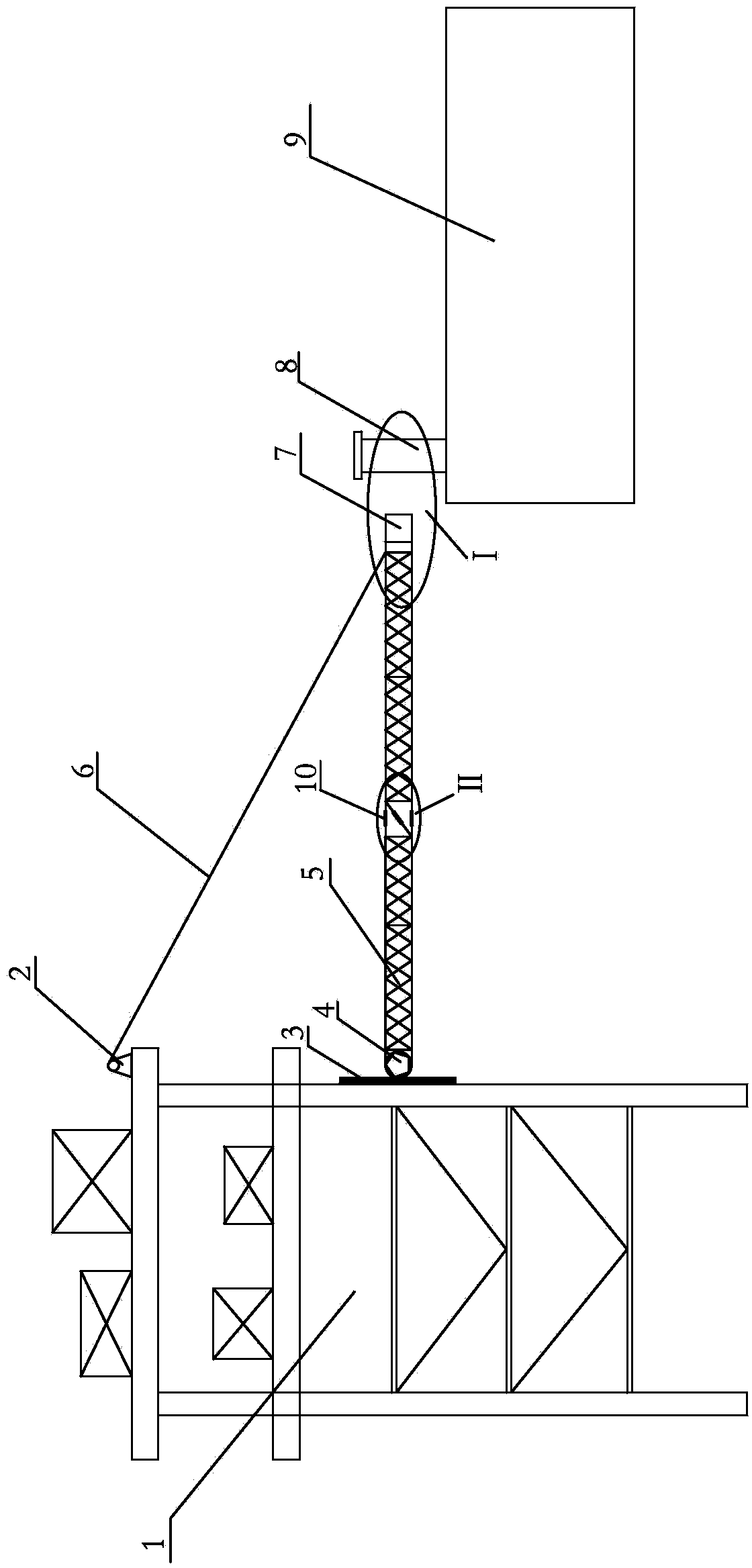

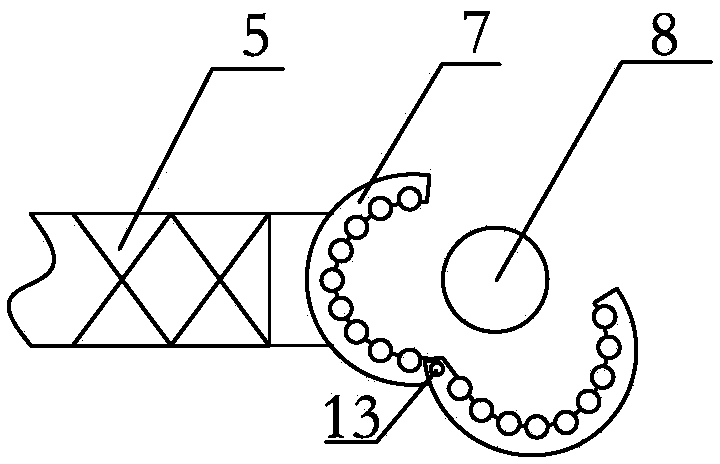

[0013] Such as figure 1 As shown, when the outrigger type slidable anti-collision connection device of the ship docked by the platform of the present invention is in the working state (that is, when the work boat 9 is docked), the bidirectional shaft 4 (which can switch directions in both vertical and horizontal directions) fixed on the platform 1 device) operation, the telescopic truss arm 5 becomes horizontal, the winch 2 releases the cable 6, and the staff fixes one end of the cable to the end of the truss arm 5, and then the hydraulic device works, and the truss arm 5 extends outward to keep the cable tight. Stretching, the manipulator 7 at the end is opened to search for the ship pillar 8, when the manipulator 7 touches the pillar 8, close the manipulator 7, and complete the connection with the connection end 8 of the working ship 9. The working diagram of manipulator 7 is shown in image 3 , it is connected by hinge 13 by two semicircular claws. The inner sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com