Preparation method of carbon cloth with wet chemical modified surface

A technology of wet chemistry and carbon cloth, which is applied in the fields of carbon fiber, textiles, papermaking, fiber treatment, etc. It can solve the problems of difficult control of surface uniformity and limited number of functional groups on the surface of carbon fiber, and achieve controllable conditions, low cost and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

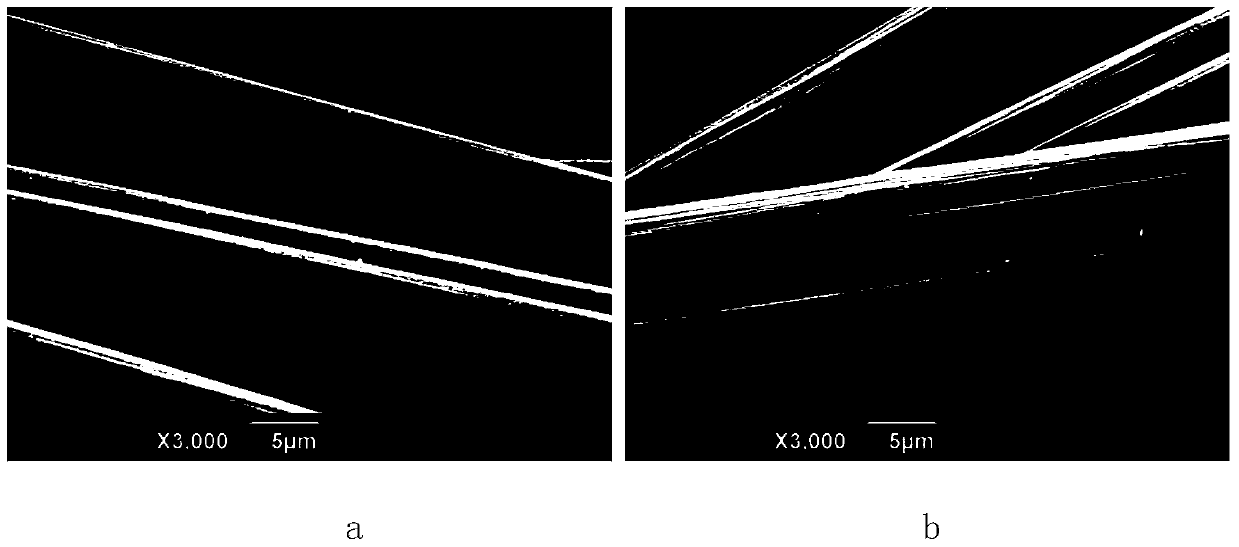

Image

Examples

Embodiment 1

[0017] 1) Cut the carbon cloth into a rectangular shape of 5cm×7cm, soak it in acetone solution for 24 hours to make it soak, then take it out and dry it under natural conditions to obtain sample A;

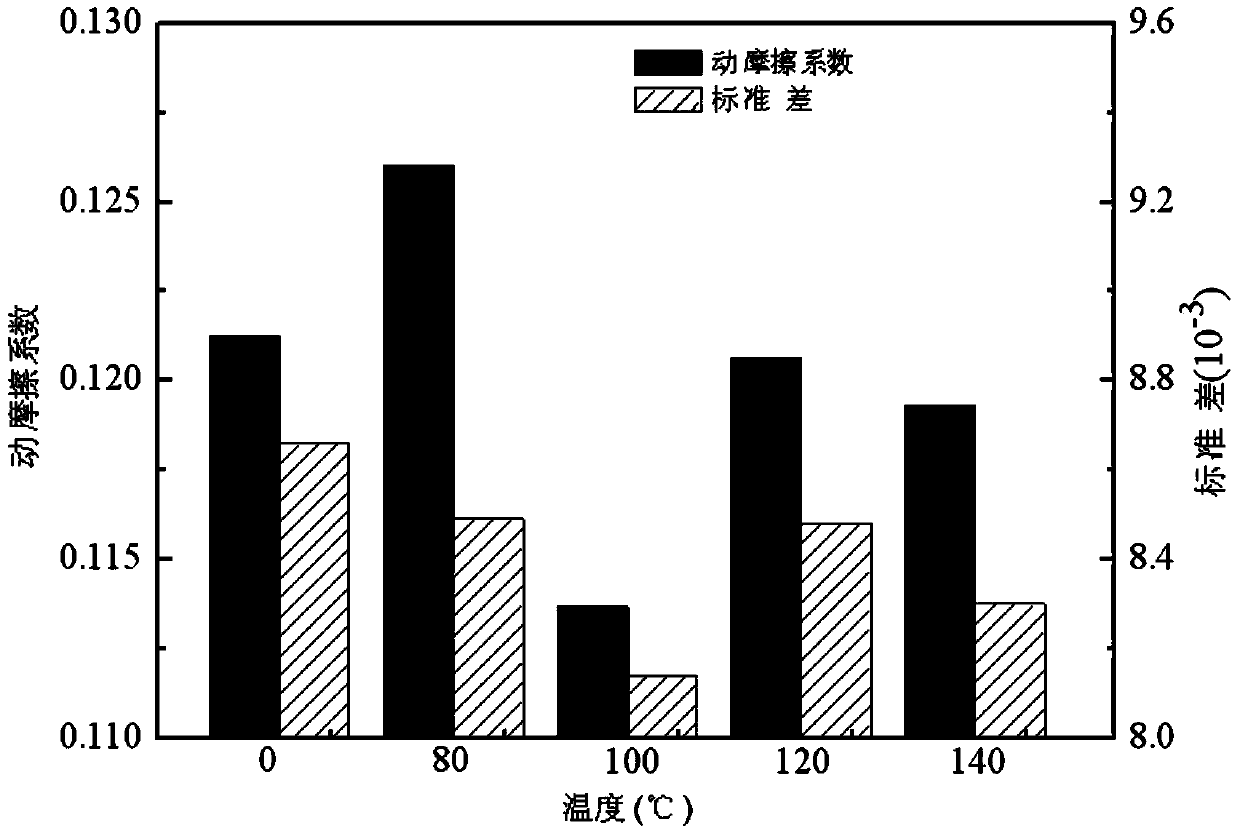

[0018] 2) Put sample A and concentrated nitric acid into a hydrothermal reaction kettle, then put the hydrothermal reaction kettle into a homogeneous reactor at 140°C for 1 hour, take out the carbon cloth after the reaction, and clean it with deionized water , and finally vacuum-dried at 80°C to obtain a carbon cloth whose surface has undergone wet chemical modification; wherein, the volume content of concentrated nitric acid in the hydrothermal reaction kettle is 30%.

Embodiment 2

[0020] 1) Cut the carbon cloth into a rectangular shape of 5cm×7cm, soak it in acetone solution for 24 hours to make it soak, then take it out and dry it under natural conditions to obtain sample A;

[0021] 2) Put sample A and concentrated nitric acid into a hydrothermal reaction kettle, then put the hydrothermal reaction kettle into a homogeneous reactor at 120°C for 2 hours, take out the carbon cloth after the reaction, and clean it with deionized water , and finally vacuum-dried at 80°C to obtain a carbon cloth whose surface has undergone wet chemical modification; wherein, the volume content of concentrated nitric acid in the hydrothermal reaction kettle is 40%.

Embodiment 3

[0023] 1) Cut the carbon cloth into a rectangular shape of 5cm×7cm, soak it in acetone solution for 24 hours to make it soak, then take it out and dry it under natural conditions to obtain sample A;

[0024] 2) Put sample A and concentrated nitric acid into a hydrothermal reaction kettle, then put the hydrothermal reaction kettle into a homogeneous reactor at 100°C for 3 hours, take out the carbon cloth after the reaction, and clean it with deionized water , and finally vacuum-dried at 80°C to obtain a carbon cloth whose surface has undergone wet chemical modification; wherein, the volume content of concentrated nitric acid in the hydrothermal reaction kettle is 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com