Preparation method of sweet-taste tipping paper

A technology for tipping paper and sweetness, applied in papermaking, paper coatings, textiles and papermaking, etc., can solve the problem of inconspicuous sweetness, achieve obvious sweetness, reduce flavor loss, and increase features and highlights.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

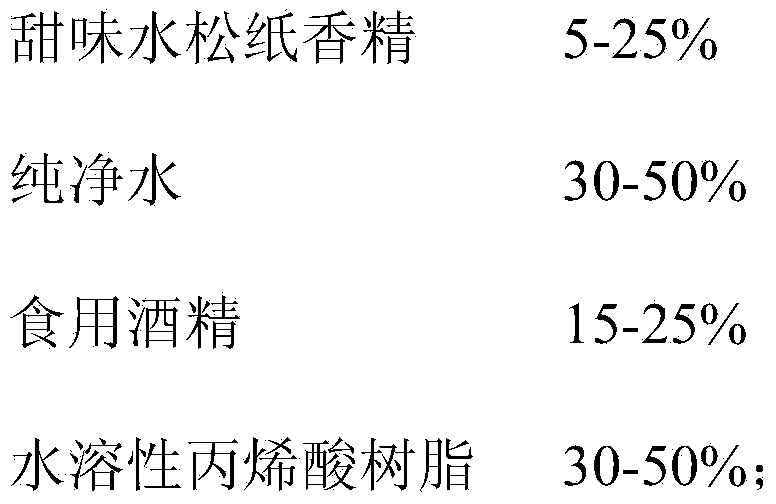

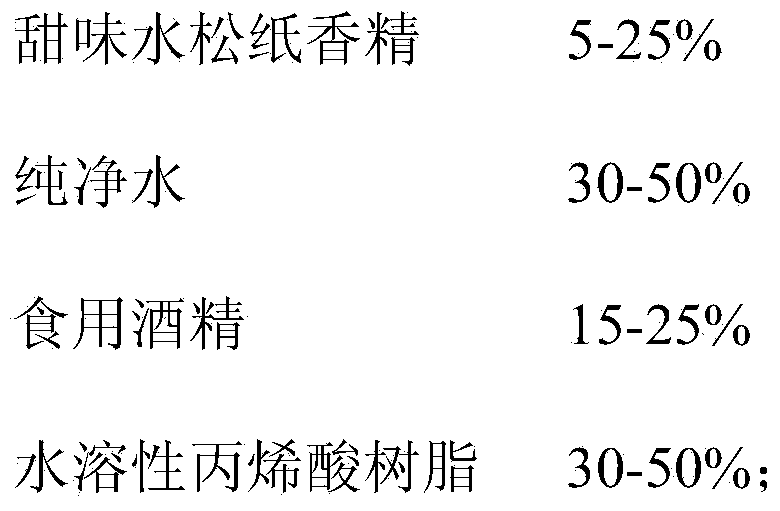

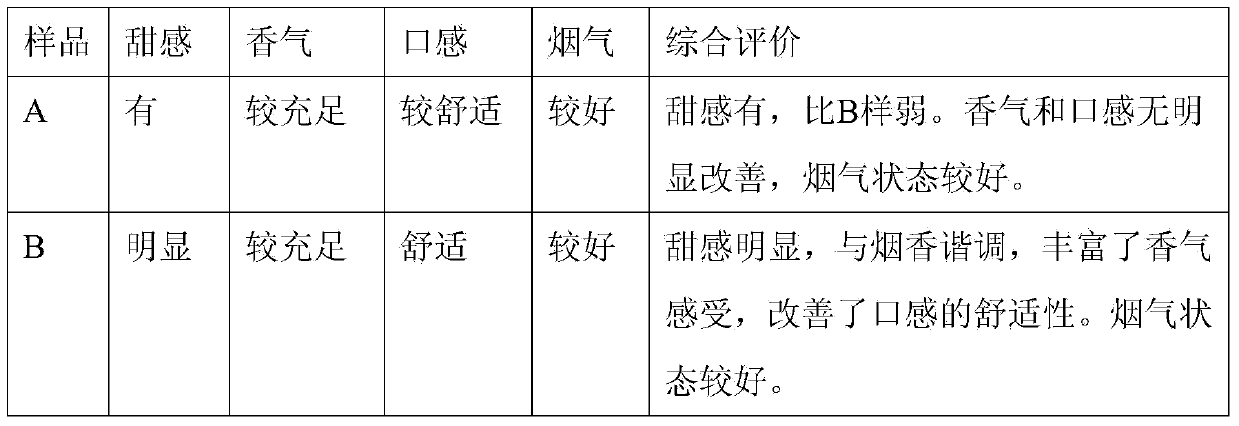

Embodiment 1

[0022] Weigh the following raw materials in parts by weight: grape juice: 10 parts, sucrose: 10 parts, apple cider vinegar: 5 parts, sodium saccharin: 2 parts, honey: 1 part, claret oil: 1 part, raspberry ketone : 1 part, clove oil: 0.5 part, 95% alcohol: 30 parts, purified water: 39.5 parts, mix uniformly and make sweet tipping paper essence; take sweet tipping paper essence: 10 parts, purified water: 40 parts, edible alcohol: 15 parts, water-soluble acrylic resin: 35 parts, mix evenly, make sweet coating liquid, apply to the surface of cigarette tipping paper, coating amount is controlled at 1.0 g / square meter, then After drying, bronzing and other processes, the sweet tipping paper for tobacco is obtained.

Embodiment 2

[0024] Weigh the following raw materials in parts by weight: grape juice: 5 parts, sucrose: 5 parts, apple cider vinegar: 8 parts, sodium saccharin: 2 parts, honey: 2 parts, claret oil: 2 parts, raspberry ketone : 2 parts, clove oil: 1 part, 95% alcohol: 35 parts, purified water: 38 parts, mix uniformly and make sweet tipping paper essence; take sweet tipping paper essence: 15 parts, purified water: 35 parts, edible alcohol: 20 parts, water-soluble acrylic resin: 30 parts, mix evenly, make sweet coating liquid, apply to the surface of cigarette tipping paper, coating amount is controlled at 1.2 grams / square meter, then After drying, bronzing and other processes, the sweet tipping paper for tobacco is obtained.

Embodiment 3

[0026] Weigh the following raw materials in parts by weight: grape juice: 15 parts, sucrose: 10 parts, apple cider vinegar: 6 parts, sodium saccharin: 4 parts, honey: 2 parts, claret oil: 2 parts, raspberry ketone : 2 parts, clove oil: 1 part, 95% alcohol: 30 parts, purified water: 22 parts, mix uniformly and make sweet tipping paper essence; take sweet tipping paper essence: 15 parts, purified water: 45 parts, edible alcohol: 20 parts, water-soluble acrylic resin: 20 parts, mix evenly, make sweet coating liquid, apply to the surface of cigarette tipping paper, coating amount is controlled at 1.0 g / square meter, then After drying, bronzing and other processes, the sweet tipping paper for tobacco is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com