Lushan color vitreous enamel of Tang Dynasty, and production method thereof

A production method and flower glaze technology, applied in Tanglushan flower glaze porcelain and its production field, can solve the problems of poor color and texture of flower porcelain, no strong bursting, flow and three-dimensional effect, etc., and achieve natural color on the glaze surface , strong three-dimensional effect, and obvious effect of liquid-liquid phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

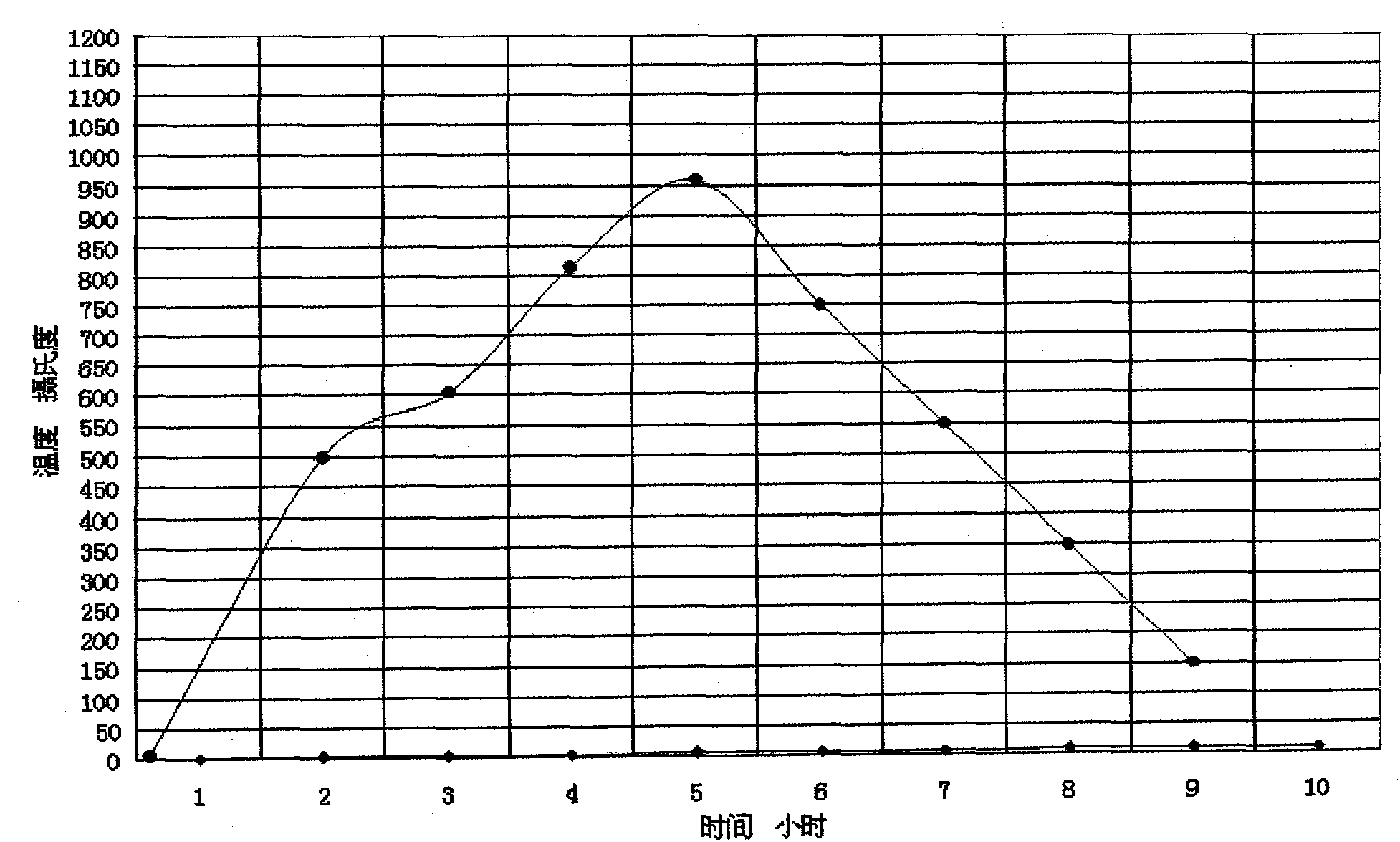

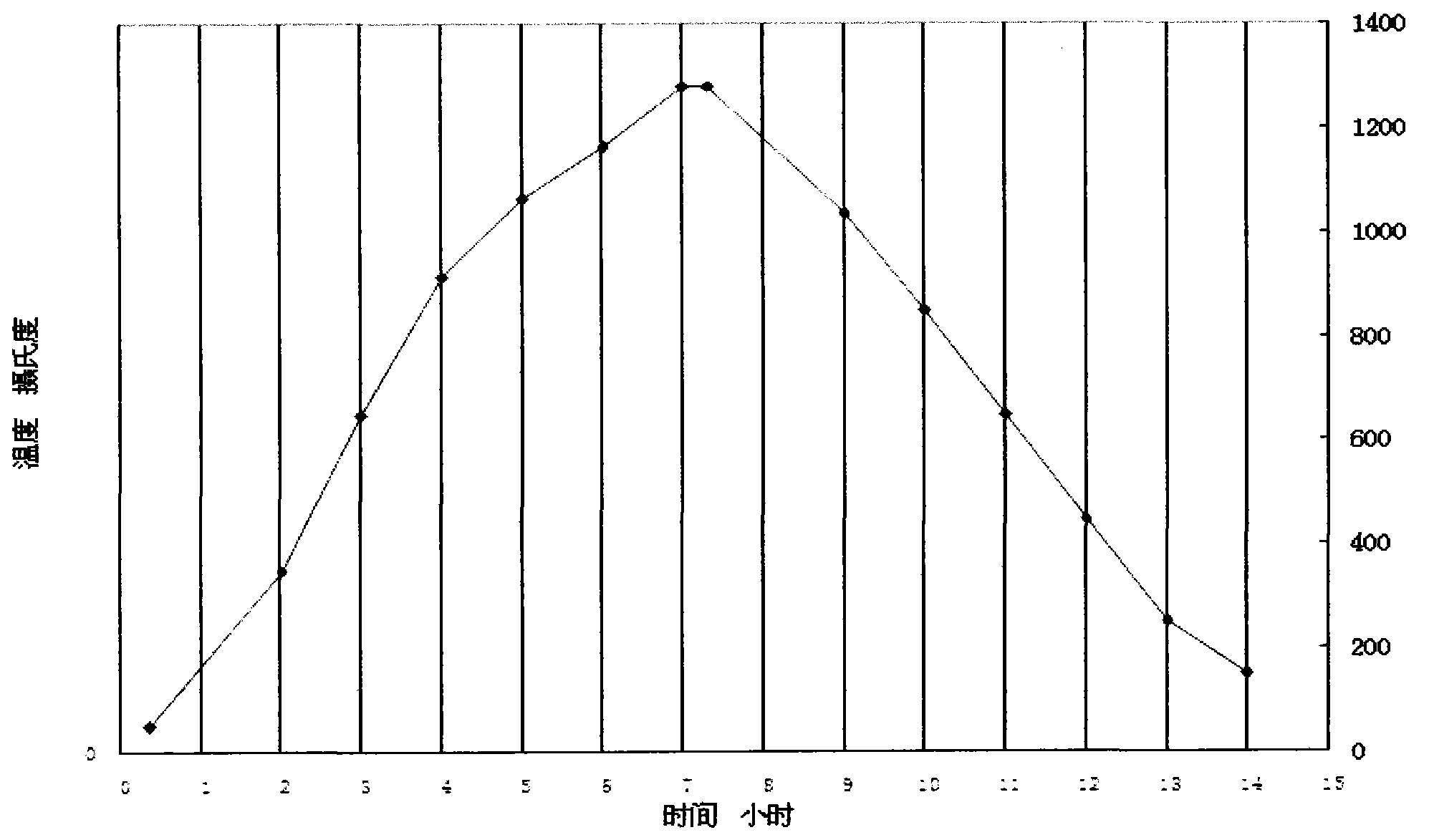

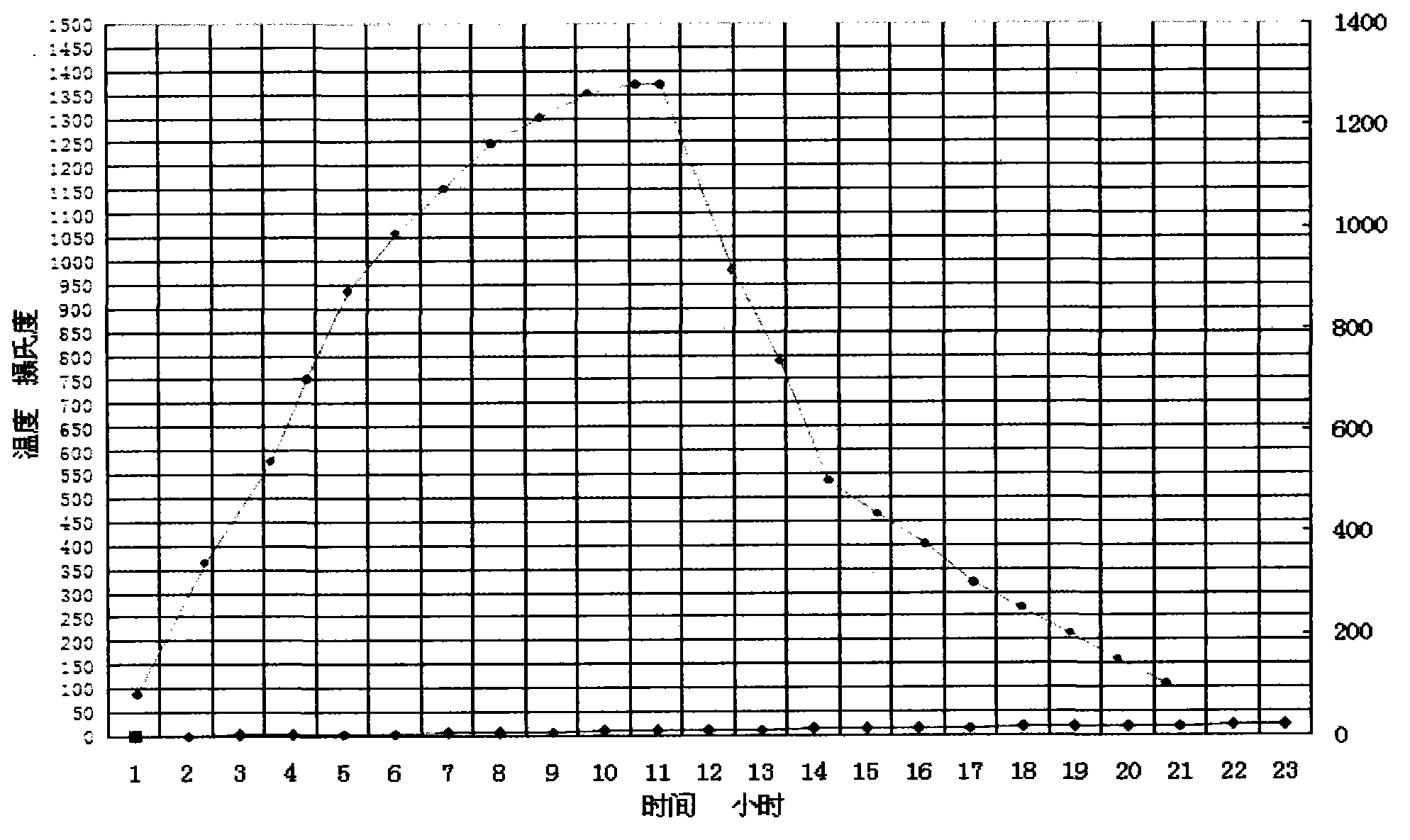

[0025] The present invention will be specifically described below in conjunction with the accompanying drawings.

[0026] Step 1. Calcining, crushing and grinding the body glaze: Lushan flower glaze porcelain is a kind of high-temperature kiln-transformed glaze porcelain with milky white and blue spots on a black ground, which is composed of a porcelain body, bottom glaze and spotted glaze. Among them; the formula of the porcelain body is: white clay 70%; leather sandstone 30%. The processing method is to mix white clay and leather sand into a ball mill to form tire material; then form ball milling balls with a water volume ratio of 1:1.3:0.7; after ball milling, the mud passed through a 100-120 mesh sieve is stale and stored or filtered Then add the mud training machine to practice mud for later use. Wherein; the formula of black base glaze is 70% by weight of black medicine; 30% by weight of black glaze stone. First, the black glaze stone is crushed into powder and passed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com