Method for making pottery brick material by modifying gold ore tailings with weakly acidic clay

A technology of gold mine tailings and weak acidity, applied in the field of tailings resource utilization technology and materials, to reduce production costs and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

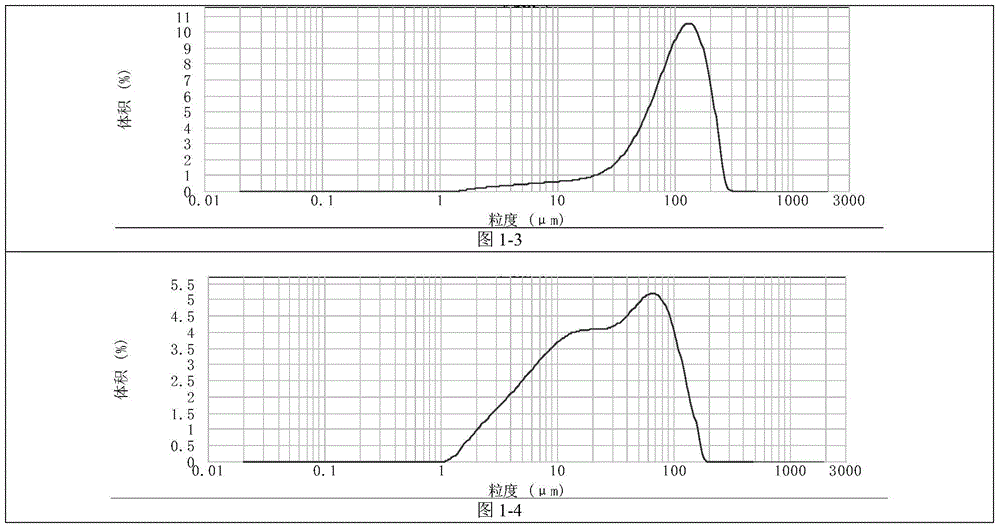

Image

Examples

Embodiment 1

[0059] First put an appropriate amount of water into the mixer, start the mixer, then add red weak acid clay, the mass ratio of weak acid clay to water is 25:4, and stir at a constant speed with the mixer to form a solid-liquid mixture of weak acid clay and water System, that is, the modified initial solution; let the modified initial solution stand at room temperature for 3-5 hours to obtain a weakly acidic modified initial solution with pH=6~7; put the weakly acidic modified initial solution into the mixer, and start the mixer , slowly add skarn-type gold tailings into the weakly acidic modified initial solution at a uniform rate, the mass ratio of gold tailings to weakly acidic clay is 1:1, stir at a constant speed with a mixer, and use weakly acidic modified initial solution to The gold tailings are modified to obtain a mixed system of "modified tailings-modified initial liquid"; the stirring process of the mixer runs through the whole process. Put the "modified tailings-m...

Embodiment 2

[0062] First put an appropriate amount of water into the mixer, start the mixer, then add red weak acid clay, the mass ratio of weak acid clay to water is 5:2, stir at a constant speed with the mixer to form a solid-liquid mixture of weak acid clay and water System, that is, the modified initial solution; let the modified initial solution stand at room temperature for 3-5 hours to obtain a weakly acidic modified initial solution with pH=6~7; put the weakly acidic modified initial solution into the mixer, and start the mixer , slowly add skarn-type gold tailings into the weakly acidic modified initial solution at a uniform rate. The gold tailings are modified to obtain a mixed system of "modified tailings-modified initial liquid"; the stirring process of the mixer runs through the whole process. Put the "modified tailings-modified initial liquid" mixed system for standing maintenance at room temperature, and when the system has a certain plasticity, the curing is completed, and...

Embodiment 3

[0065] First put an appropriate amount of water into the mixer, start the mixer, then add cyan weak acid clay, the mass ratio of weak acid clay to water is 2:1, stir at a constant speed with the mixer to form a solid-liquid mixture of weak acid clay and water System, that is, the modified initial solution; let the modified initial solution stand at room temperature for 3-5 hours to obtain a weakly acidic modified initial solution with pH=6~7; put the weakly acidic modified initial solution into the mixer, and start the mixer , slowly add ductile shear band type gold tailings into the weakly acidic modified initial solution at a uniform rate, the mass ratio of gold tailings to weakly acidic clay is 4:1, stir at a constant speed with a mixer, and use weakly acidic modified initial solution The gold tailings are modified to obtain a "modified tailings-modified initial liquid" mixed system; the stirring process of the mixer runs through the whole process. Put the "modified tailing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com