Method for directly preparing zirconium deuteride by using high temperature direct method

A technology of zirconium deuteride and direct method, which is applied in the interdisciplinary field of material science and nuclear science, can solve the problems of unfavorable industrial scale production of zirconium deuteride, and achieve simple and easy-to-purchase preparation equipment, good product stability, and harmless to human body and environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

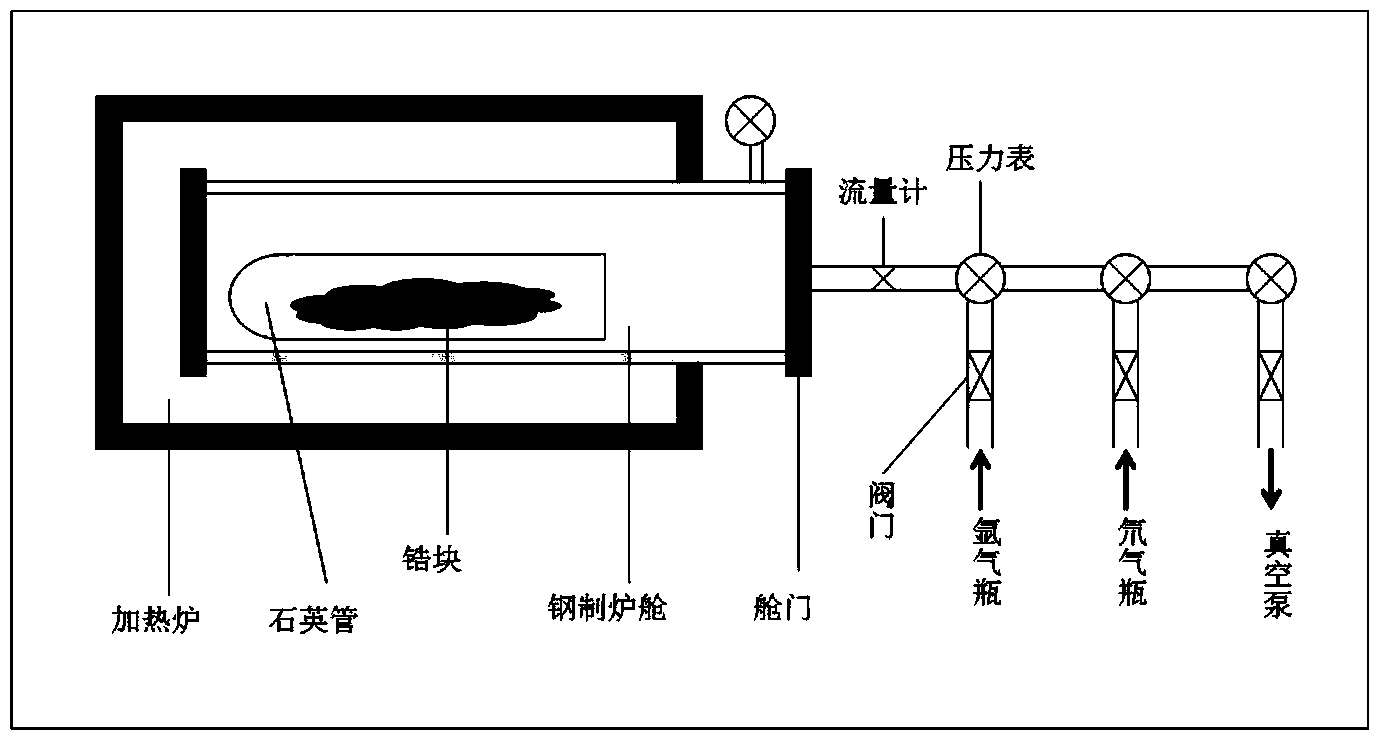

[0023] Metal zirconium with a purity of 99.4% was cut into small pieces with a particle size of 2 mm, weighed 503 g, and packed into a quartz glass tube. Under the protection of argon, place the quartz tube in the high-temperature heating furnace cabin, and close the furnace cabin, such as figure 1 shown. Introduce argon gas to replace the gas in the furnace chamber, and pump the pressure in the chamber to a negative pressure of 0.025MPa, then pass in deuterium gas with a purity of 99.999% to replace the argon in the chamber, and pump it again to a negative pressure of 0.018MPa, Repeat the operation 3 times; quickly raise the temperature to 567°C at a heating rate of 30°C / min, pass in deuterium gas, control the flow rate at 903ml / min, and heat at a rate of 10°C / min for 43 minutes to 890°C to stop heating , constant temperature and deuterium gas flow rate, and continue to react for 122min. At this time, the deuterium pressure gauge and the pressure in the heating reaction furn...

Embodiment 2

[0025] Metal zirconium with a purity of 99.99% is cut into small pieces with a particle size of 8mm, weighed 1400g of the zirconium piece, put it into a quartz glass tube, put the quartz tube in a high-temperature heating furnace cabin, and close the furnace cabin. Control the ventilation valve, and after argon gas is introduced into the furnace cabin, the pressure in the cabin is pumped to a negative pressure of 0.019MPa, and then high-purity deuterium gas is introduced. After repeated operations 4 times, all valves are closed. Rapidly raise the temperature to 586°C at a heating rate of 20°C / min, open the deuterium gas valve, and introduce deuterium gas with a purity of 99.999%, control the flow rate at 1994ml / min, and raise the temperature at a rate of 15°C / min for 36 minutes Stop heating at 867°C, keep the temperature and deuterium flow rate constant, and continue to react for 164 minutes. At this time, the deuterium pressure gauge and the pressure in the heating reaction fu...

Embodiment 3

[0027] Metal zirconium pieces with a purity of 99.99% and a particle size of 15mm were stirred in aqua regia at 5°C for 10 minutes under the protection of argon, washed 4 times with deionized water, and dried in vacuum; under the protection of argon, weigh the above-mentioned Put 2802g of zirconium block into the quartz glass tube, and plug the nozzle with a rubber stopper; under the protection of argon, place the quartz tube in the high-temperature heating furnace cabin, quickly pull out the rubber stopper and quickly close the furnace cabin; After replacing the gas in the furnace chamber with gas, the pressure in the chamber is pumped to a negative pressure of 0.022MPa, and then 99.999% deuterium gas is introduced, and the operation is repeated 3 times; Deuterium gas, control the flow rate at 4499ml / min, and at the same time raise the temperature at a rate of 10°C / min for 52min to 862°C to stop heating, keep the temperature and deuterium flow rate constant, and continue to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com