Onboard device suitable for sowing job of unmanned aerial vehicle and sowing method

A technology for airborne devices and unmanned aerial vehicles, which is applied to launch devices, aircraft parts, transportation and packaging, etc., can solve the problems of strict requirements for operators, large size, poor flexibility, etc., and achieves good dissemination effect, small size and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

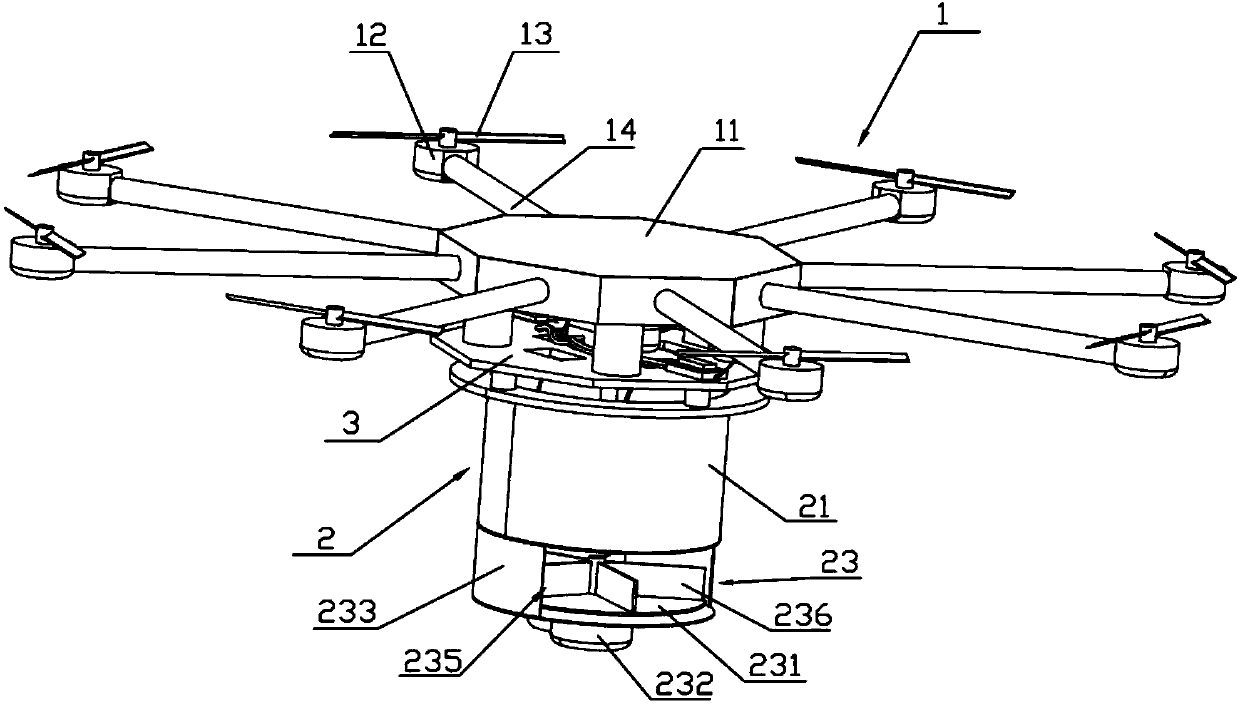

[0046] see figure 1 , the airborne device suitable for unmanned aerial vehicle sowing operations in this embodiment includes a spreading device 2 arranged under the unmanned aerial vehicle 1 .

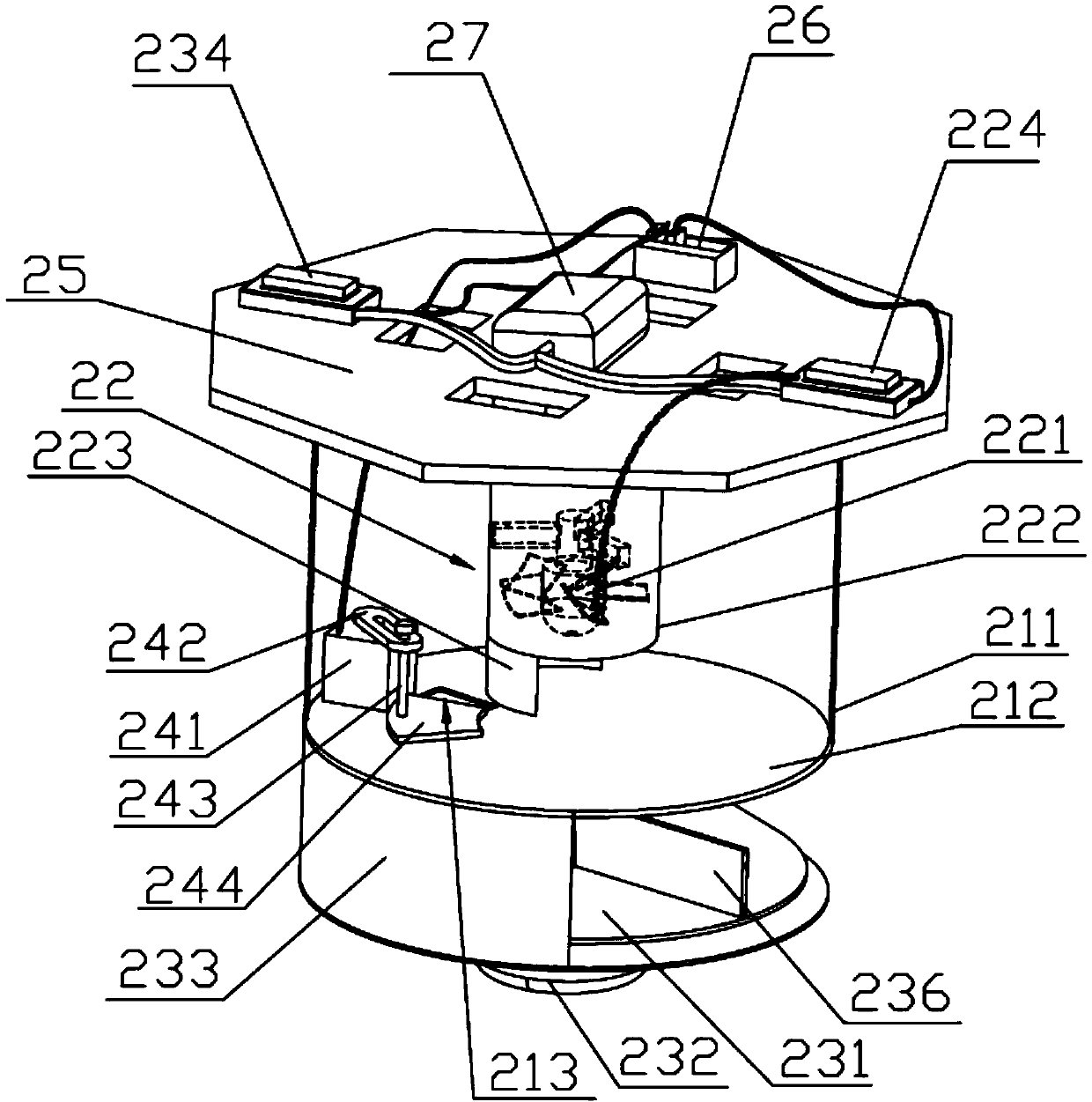

[0047] see figure 1 and figure 2 , the spreading device 2 includes a material box 21, a material stirring mechanism 22, a discharge adjustment mechanism 24, a material spreading mechanism 23 and a load plate 25, wherein the material stirring mechanism 22 is arranged in the material box 21, and the material spreading The mechanism 23 is arranged under the material box 21 , and the load plate 25 is arranged at the upper end of the material box 21 .

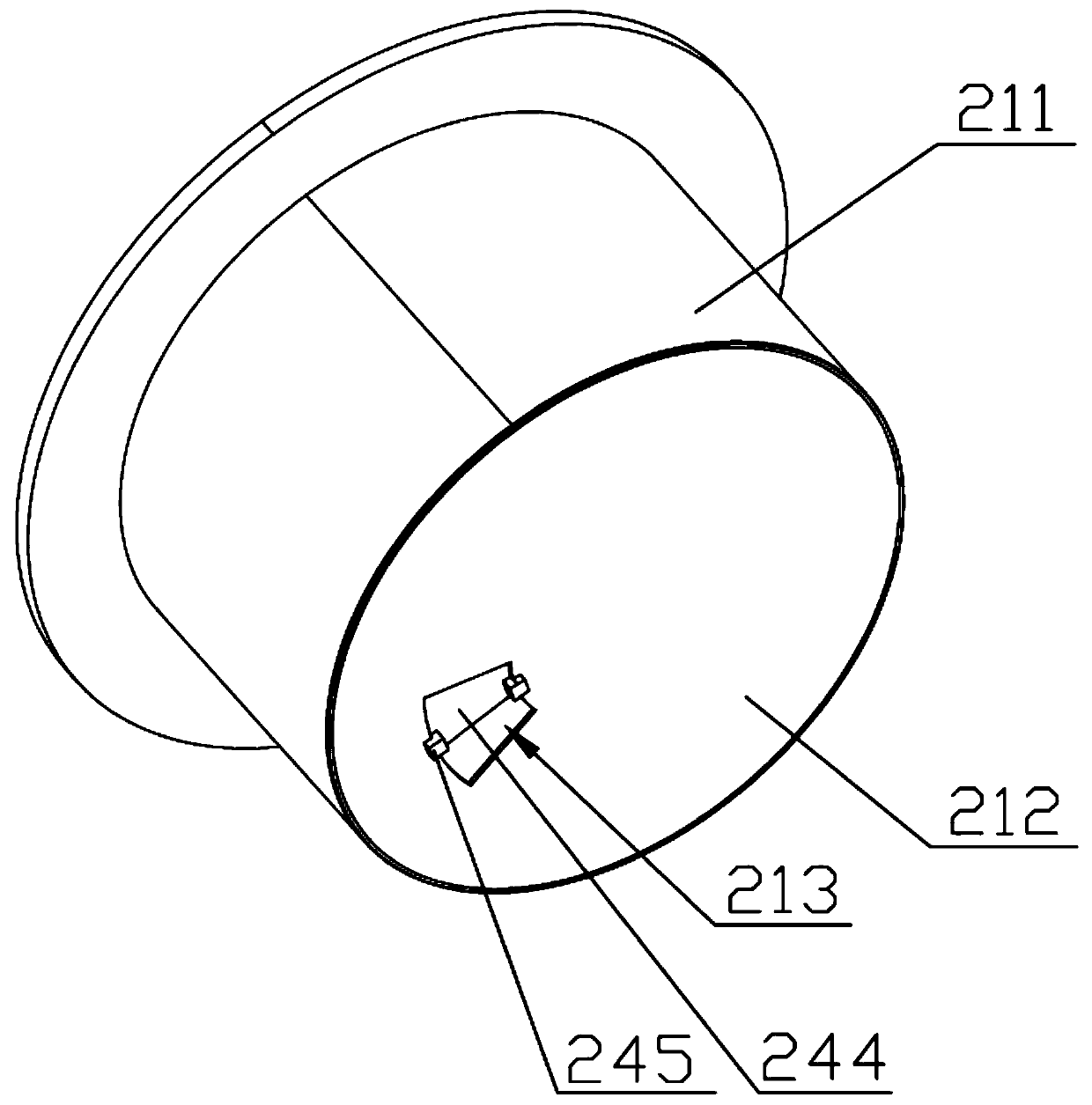

[0048] Figure 1 ~ Figure 3 , the material box 21 is composed of a box wall 211 with a circular cross section and a bottom plate 212, wherein the bottom plate 212 is provided with a leak 213 for dropping materials such as seeds or fertilizers. The material box 21 has a rigid body structure and is made of plastic light materials to reduc...

Embodiment 2

[0064] Referring to 4, the difference between this embodiment and Embodiment 1 is that in this embodiment, the material stirring mechanism 22 adopts a blade mechanism, and the blade mechanism includes a motor and a blade connected to the motor. Wherein, the motor is fixed on the load plate 25 through the connecting rod 243 ; the blade is arranged coaxially with the material box 21 , and its turning direction is opposite to that of the wheel disc 231 in the material spreading mechanism 23 . The material particles are directly agitated by the blades, so that the material particles are kept uniformly distributed in the material box 21 , thereby ensuring that the materials around the leak 213 can fall evenly.

Embodiment 3

[0066] The difference between this embodiment and Embodiment 1 is that in this embodiment, on the basis of one ducted fan mechanism in Embodiment 1, the material stirring mechanism is also provided with two other ducted fan mechanisms. The axial direction of the ducted fan of the first ducted fan mechanism is perpendicular to the axial direction of the ducted fan of the first ducted fan mechanism, and the rotation direction of the ducted fan in the two ducted fan mechanisms is opposite. This allows the material to be fully stirred in the material box, so that the intertwined material particles (such as sprouted seeds) are fully separated so that they can evenly fall from the leak.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com