Two-stage four-drum forming machine for all-steel truck radical tires

A technology for radial tires and building machines, which can be applied to tires, other household appliances, household appliances, etc., and can solve problems that affect the service life of tires, the safety of drivers and passengers, the high cost of tire repair or recycling, and poor tread wear resistance. , to achieve the effect of low installation and manufacturing precision requirements, simple structure, and improved molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

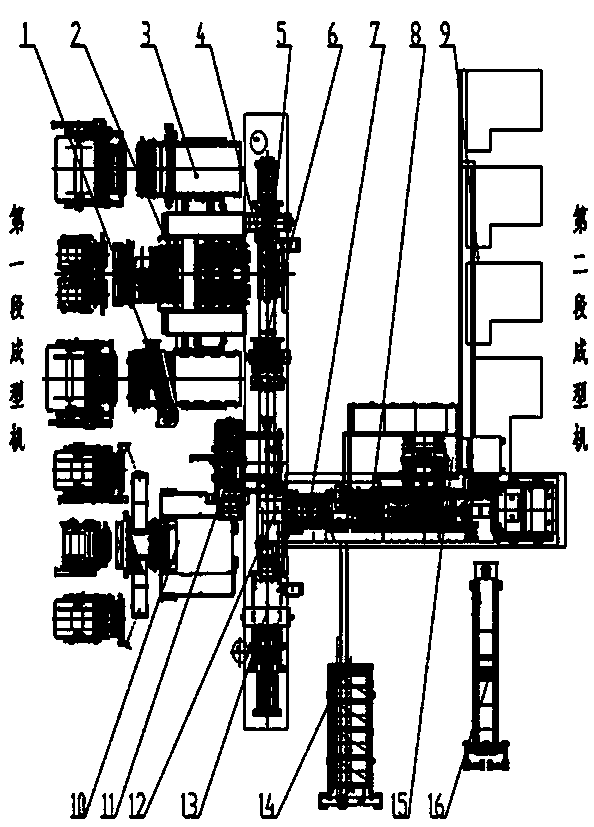

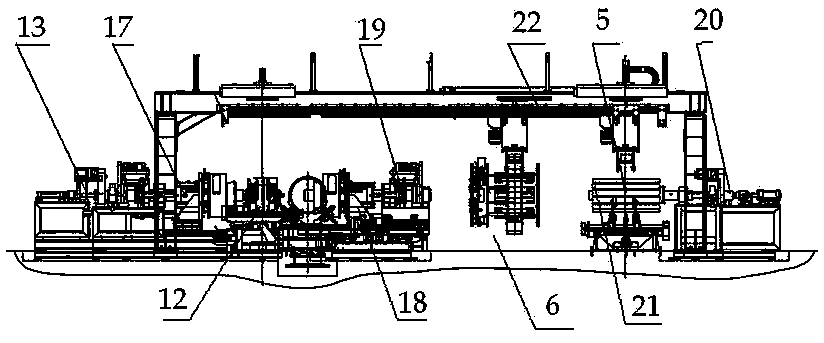

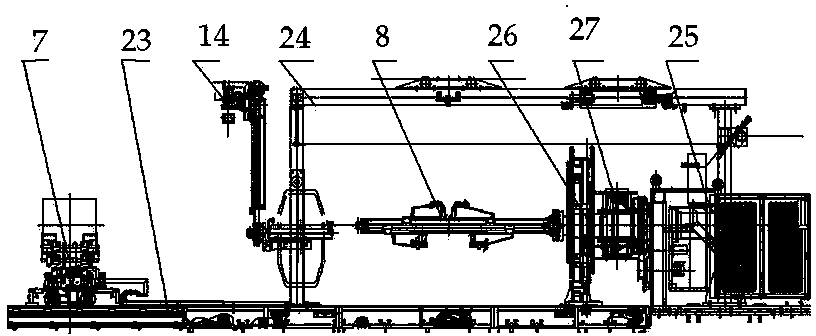

[0031] see Figure 1 to Figure 3 As shown, the present invention is composed of a one-stage forming machine and a two-stage forming machine. The one-stage forming machine includes a truss 22, a one-stage carcass fitting drum 5, a feeding rack mechanism, a carcass transfer ring 6, a one-stage forming drum host 13 and a carcass Tube transfer trolley 7; the truss 22 is an inverted U-shaped structure, and the first section of carcass fitting drum 5 and the carcass transfer ring 6 are sequentially arranged on the beam above the truss 22, and a section of carcass fitting drum 5 There is a carcass fitting drum transmission box and a set of carcass rolling device inside, the rear pressure roller 21 is located under a section of the carcass fitting drum 5, and the carcass drum main engine 20 is located on one side of the rear pressure roller 21 and passes The mechanical transmission mechanism is connected with the rear pressure roller 21, and a section of forming drum host 13 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com