Dynamic regulating system of mix proportion of concrete mixing plant

A dynamic adjustment and concrete technology, which is applied in the direction of mixing operation control, mixing operation control device, batching and batching instrument, etc., can solve the problems of unreachable concrete water consumption, concrete deviation from the target mix ratio, and lack of prior control, etc., to reduce personnel The effect of allocation and resource allocation, improvement of production quality and management level, and improvement of labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

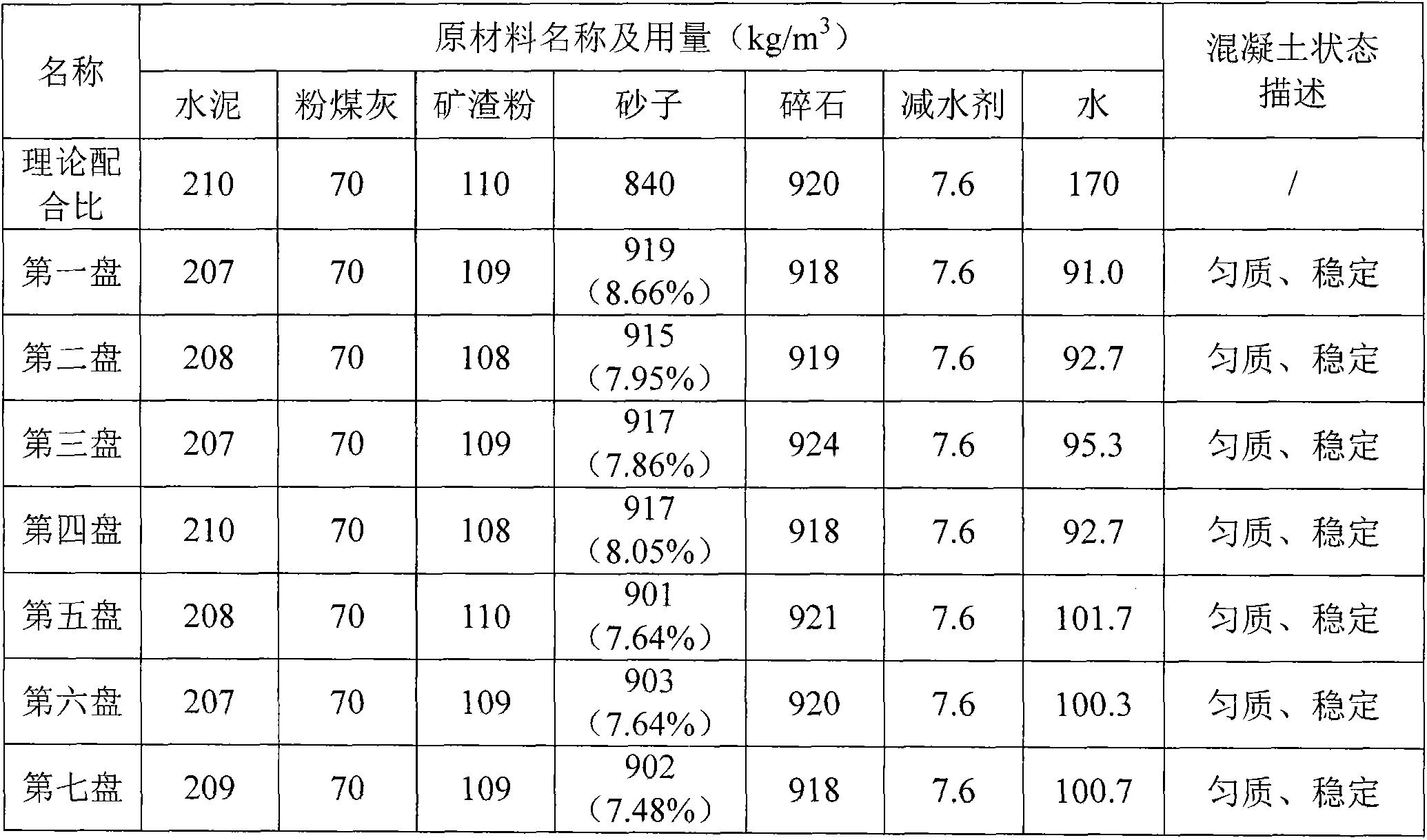

Examples

Embodiment 1

[0019] Embodiment 1, the present invention is described further in conjunction with accompanying drawing:

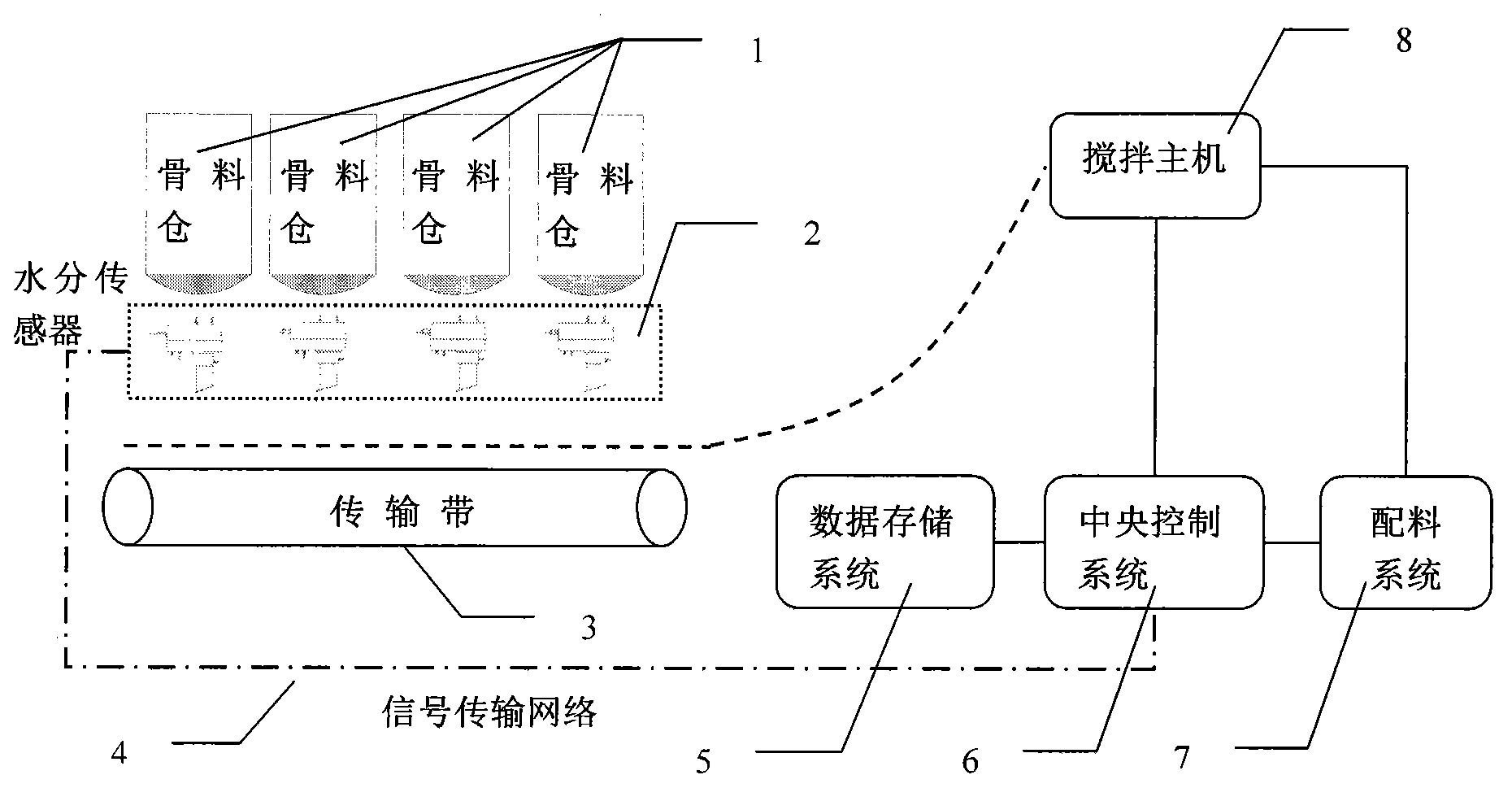

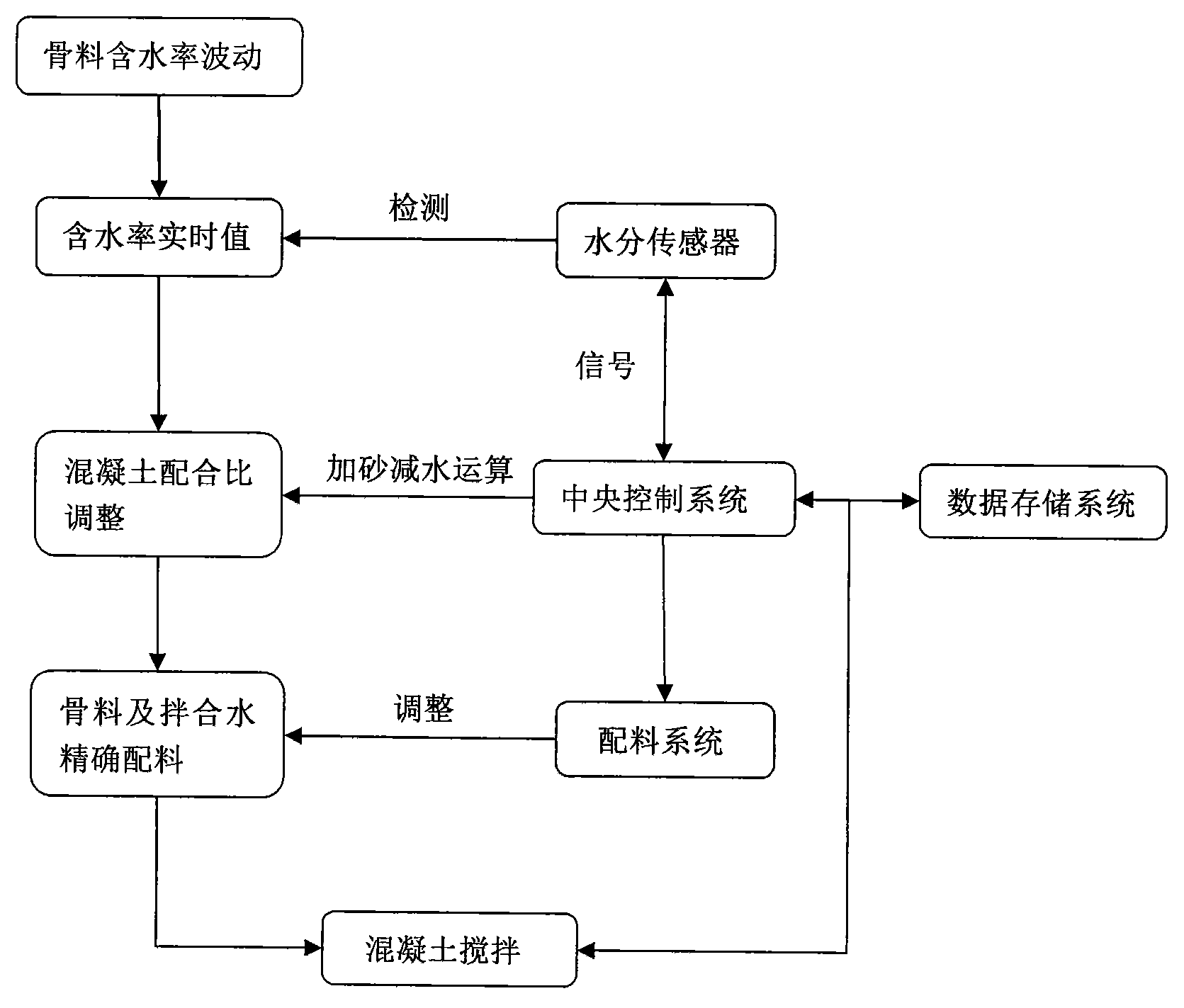

[0020] The system of the present invention comprises moisture sensor 2, signal transmission network 4, data storage system 5 and central control system 6 and is composed of four parts, specifically, moisture sensor 2 and central control system 6 are connected by signal transmission network 4; data storage system 5 and the central control system 6 are integrated with an industrial computer system, and the data storage system 5 is provided with an information interface, and data can be exchanged freely. When working, the moisture sensor 2 is installed at the discharge port of the aggregate bin 1, and multiple moisture sensors 2 can be connected to the grid; the central control system 6 automates the belt conveyor 3, the batching system 7 and the concrete mixing host 8 at the same time control.

[0021] Such as figure 1 As shown, the moisture sensor is installed below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com