High-pressure gas oil injection device

An oil injection device and high-pressure gas technology, applied in the field of aerated concrete block production equipment, can solve the problems of increased oil consumption, blockage of oil injection holes, insufficient uniformity of oil injection, etc., and achieve the effect of reducing the probability of blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The content of the present invention will be described below in conjunction with specific embodiments.

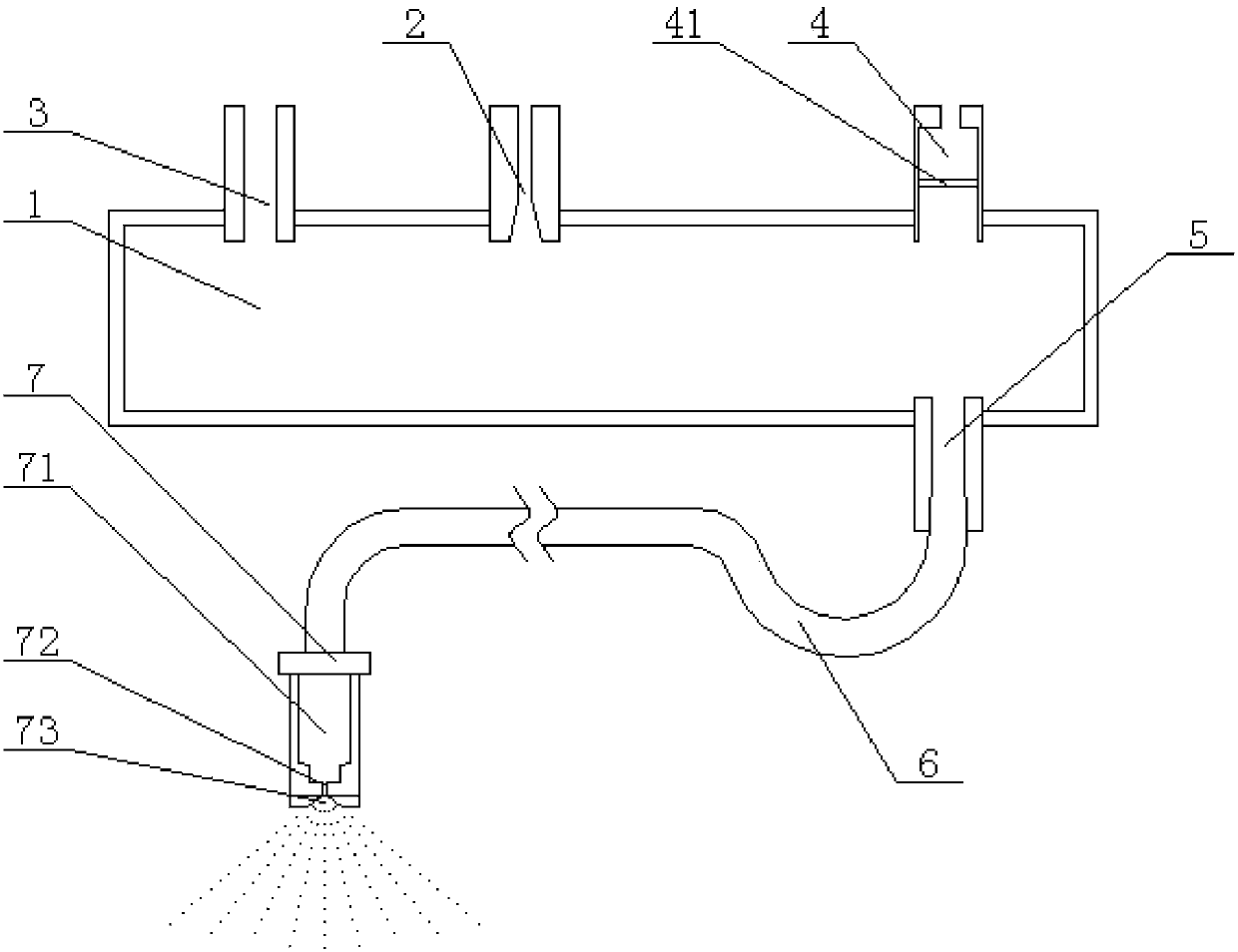

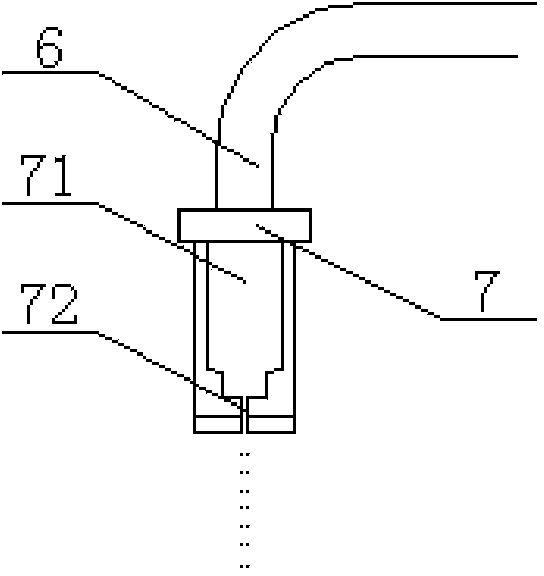

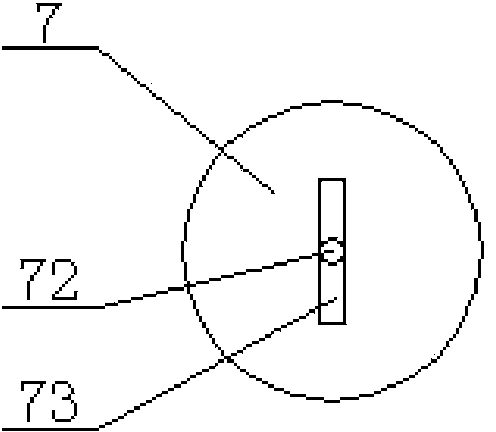

[0014] Such as Figure 1 to Figure 3 As shown, it is a structural schematic diagram of a high-pressure gas fuel injection device according to the present invention. A high-pressure gas fuel injection device according to the present invention includes: a mixing cylinder 1, an air inlet 3 is provided on the top wall of one end of the mixing cylinder 1, and an air outlet 4 is provided on the top wall of the other end of the mixing cylinder 1, so that The air outlet 4 is provided with an oil-repellent gas-permeable film 41, and the top wall of the mixing cylinder 1 is also provided with an oil inlet 2, and the oil inlet 2 is located between the air inlet 3 and the air outlet 4 , the bottom of the mixing cylinder 1 is provided with an oil outlet 5, and the oil outlet 5 and the air outlet 4 are located at the same end of the mixing cylinder 1; the connecting hose 6 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com