Preparation method of superparamagnetic bentonite-based water treatment agent

A superparamagnetic, water treatment agent technology, applied in adsorption water/sewage treatment, chemical instruments and methods, other chemical processes, etc., can solve the problems of difficult separation of liquid and solid, poor adsorption and purification of industrial wastewater, and inconvenient use. , to achieve the effect of facilitating solid-liquid separation and good adsorption and purification of industrial wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]Embodiment 1 (co-precipitation method): the preparation method of this kind of superparamagnetic bentonite-based water treatment agent, its specific production steps are: Step 1: put 1.5g of calcium-based bentonite into a 250ml flask, add 40ml of Ionized water was mechanically stirred for 1.5h.

[0034] Step 2: Prepare FeCl containing 1.39g respectively 2 ﹒ 4H 2 O and 3.77 g FeCl 3 ·6H 2 20 mL of acidic mixed solution of O and 2 g of NH 4 HCO 3 , 10 g of Na 2 CO 3 , an alkaline mixed solution of 40 mL of hydrazine hydrate of 5 grams;

[0035] Step 3: Fill the flask with N 2 Finally, with the ratio of acidic solution: alkaline solution = 1:2, the acidic solution and the alkaline solution were added to the flask containing the bentonite suspension at a simultaneous drop rate, and heated in a water bath for 2 hours.

[0036] Step 4: stop heating and cool to room temperature, perform magnetic separation and wash with absolute ethanol for 3 to 5 times.

[0037] Ste...

Embodiment 2

[0040] Example 2 (co-precipitation method): the preparation method of superparamagnetic bentonite-based water treatment agent, its specific production steps are: Step 1: Add 30mL of deionized water to a 250mL flask containing 1g of calcium-based bentonite, and mechanically stir for 1h for later use.

[0041] Step 2: prepare FeSO containing 1.94g respectively 4 ·7H 2 O and 3.77 g FeCl 3 ·6H 2 20mL acidic mixed solution of O and 8.0g of Na 2 CO 3 , 40mL alkaline mixed solution of 0.5g NaOH;

[0042] Step 3: Fill the flask with N 2 Finally, the acid-base solution was simultaneously added to the flask containing the bentonite suspension at a rate of 1:2, while heating in a water bath for 2 hours.

[0043] Step 4: stop heating and cool to room temperature, perform magnetic separation and wash with absolute ethanol for 3 to 5 times.

[0044] Step 5: After washing, vacuum-dry at 60° C. for 3-6 hours, grind and pass through a 120-mesh sieve to obtain a superparamagnetic benton...

Embodiment 3

[0047] Embodiment three (thermal decomposition method): the preparation method of superparamagnetic bentonite-based water treatment agent, its specific preparation steps are:

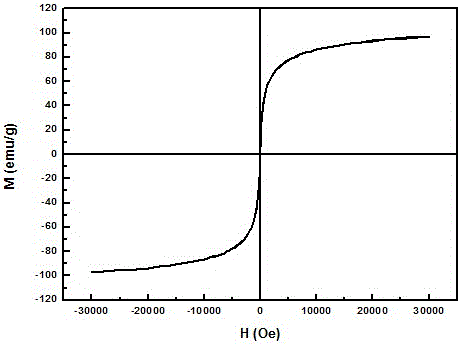

[0048] Weigh 4.0g of Fe(NO 3 ) 3 ﹒ 9H 2 O joins N 2 Dissolve 20mL of absolute ethanol in a protected autoclave, add 3.6g of urea, stir for 20min, add 0.5g of oleic acid, heat up to 100°C, then add 0.5g of calcium-based bentonite, take it out and dry it in vacuum at 60°C for 6h , then heated up to 200°C for 5 hours, cooled to room temperature, washed with absolute ethanol for 3 to 5 times, and then subjected to magnetic separation. Vacuum dry at 60°C for 3-6 hours, grind and pass through a 120-mesh sieve to obtain a superparamagnetic bentonite-based water treatment agent with a saturation magnetization of about 88emu / g.

[0049] Taking methylene blue as the simulated wastewater, the concentration of methylene blue is 4.0mg / L. Add 0.5g of magnetic bentonite sample to 50mL of wastewater, shake it bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com