Preparation method and application of hybridization reverse osmosis membrane

A reverse osmosis membrane, hybrid technology, applied in chemical instruments and methods, osmosis/dialysis water/sewage treatment, reverse osmosis, etc., can solve problems such as the decline of desalination rate, the destruction of desalination layer, and the reduction of membrane service life. Ease of use, guaranteed longevity, good flux and salt rejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

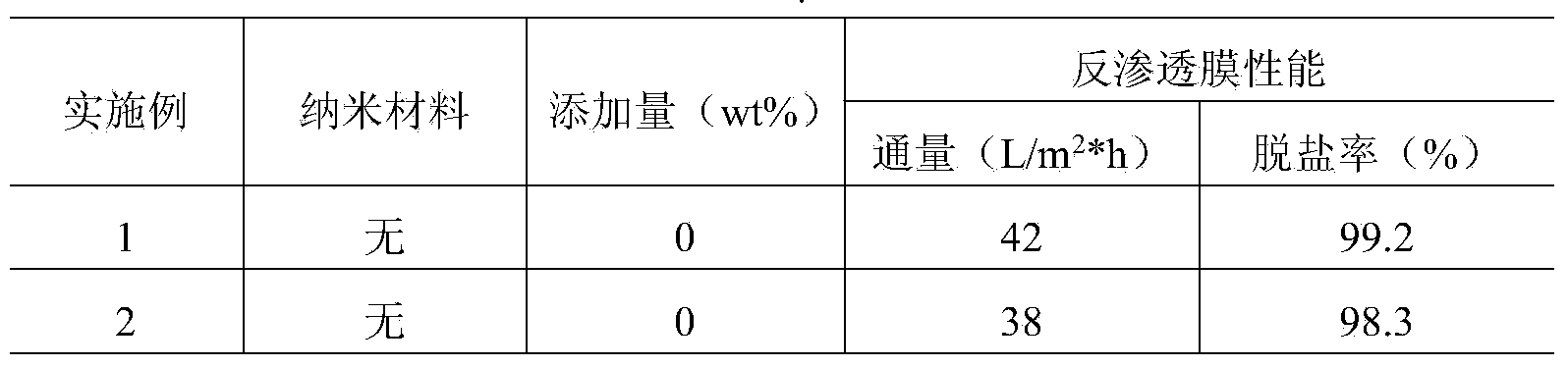

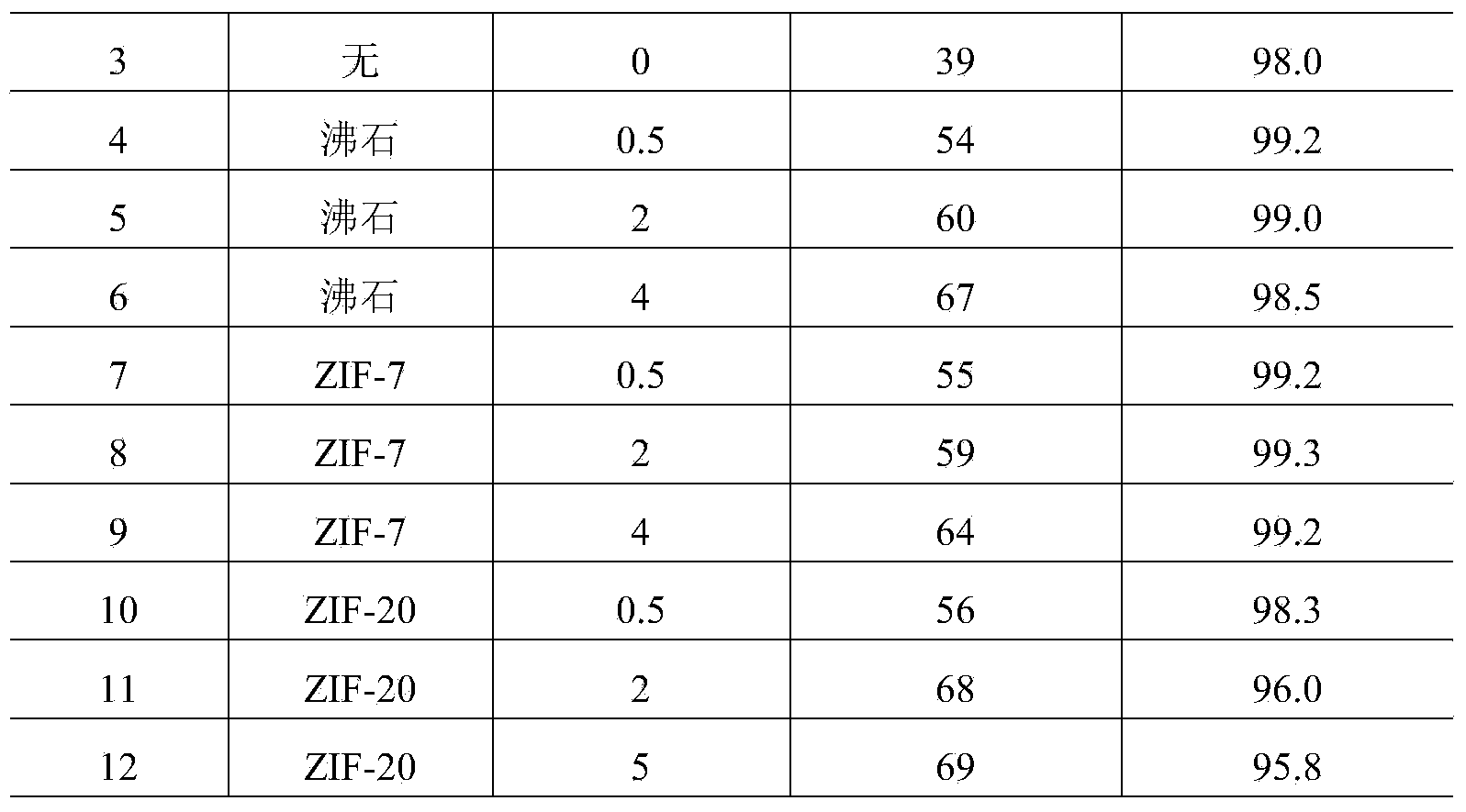

Examples

Embodiment 1

[0058] Take 18 parts of polysulfone, 6 parts of PEG4006 and DMF to make up to 100 parts, mix and stir to obtain a membrane-forming solution. The membrane-making solution is evenly coated on the non-woven support layer, and the excess membrane-making solution on the surface is scraped off to obtain a hybrid ultrafiltration base membrane.

[0059] The aqueous phase solution is 4 parts of m-phenylenediamine, 2 parts of triethylamine, and pure water to make up to 100 parts, and its pH value is measured to be 8. Soak the base film in the water phase solution for 60 seconds, remove excess water phase solution on the surface after taking it out.

[0060] The oil phase solution is a solution of trimesoyl chloride in ethylcyclohexane with a concentration of 0.09 wt%. Soak the above-mentioned basement membrane soaked in the aqueous phase solution in the oil phase solution for 20 seconds, then put it into an oven at 100° C. for 5 minutes, take it out, and rinse it with pure water for 20...

Embodiment 2

[0062] Take 10 parts of polysulfone, 1 part of PEG8001 and N-methylpyrrolidone to make up to 100 parts, mix and stir to obtain a membrane-forming solution. The membrane-making solution is evenly coated on the non-woven fabric support layer, and the excess membrane-making solution on the surface is scraped off with a scraper to obtain a hybrid ultrafiltration base membrane.

[0063] The aqueous phase solution is 5 parts of p-phenylenediamine, 0.5 part of sodium hydroxide, and pure water to make up to 100 parts, and the measured pH value is 10. Soak the base film in the water phase solution for 80 seconds, remove the excess water phase solution on the surface after taking it out.

[0064] The oil phase solution is a n-hexane solution of terephthaloyl chloride with a concentration of 0.2 wt%. Soak the above-mentioned basement membrane soaked in the aqueous phase solution in the oil phase solution for 40 seconds, then put it into an oven at 120° C. for 3 minutes, take it out, and...

Embodiment 3

[0066] The same process as in Example 1, except that the film-forming solution is 20 parts of polysulfone, 8 parts of polyvinylpyrrolidone, and dimethylacetamide to make up to 100 parts.

[0067] The aqueous phase solution is 0.1 part of 1,6-hexamethylenediamine, 2 parts of sodium phosphate, and pure water to make up to 100 parts, and the measured pH value is 9. Soak the base film in the water phase solution for 30 seconds, remove the excess water phase solution on the surface after taking it out.

[0068] The oil phase solution is an Isopar E solution of isophthaloyl dichloride with a concentration of 0.05 wt%. Soak the above-mentioned basement membrane soaked in the aqueous phase solution in the oil phase solution for 60 seconds, then put it into an oven at 50° C. for 10 minutes, take it out, and rinse it with pure water for 20 minutes to obtain a hybrid reverse osmosis membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com