A kind of preparation method of protein sauce

A production method and technology of seasoning sauce, applied in the functions of food ingredients, food science, application, etc., can solve problems such as disadvantages, achieve moderate price, large market potential, and increase the effect of flavor and texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

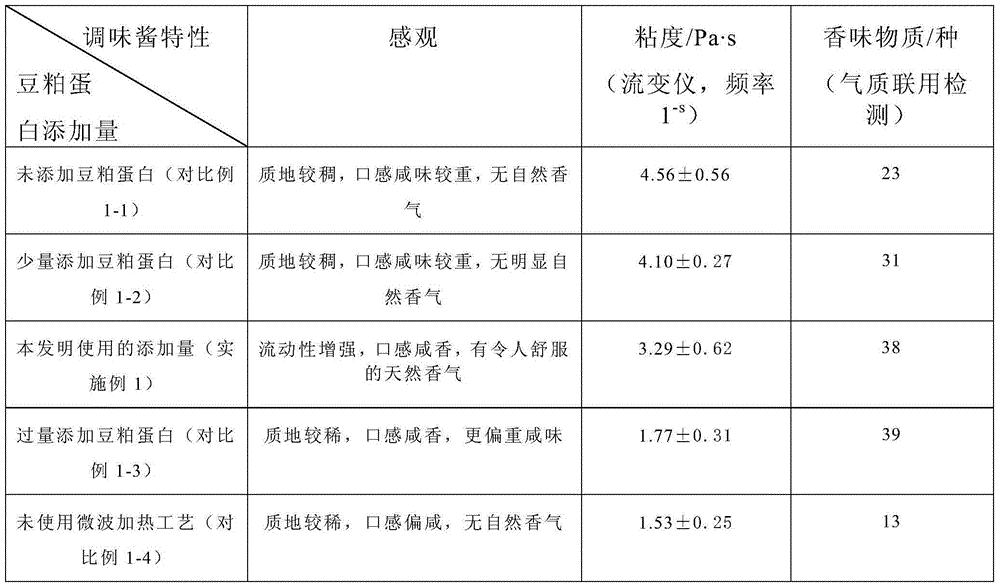

Embodiment 1

[0029] A preparation method of protein seasoning sauce, comprising the following steps:

[0030] (1) The high-temperature soybean meal is crushed into powder, 5 times the mass of purified water is added, and stirred evenly to obtain a soybean meal powder solution. Alkaline protease was added to the soybean meal powder solution, and placed in a 1.5kw ultrasonic wave for 20 minutes. The solution was placed in a constant temperature centrifuge at 20°C, centrifuged at 5000 rpm for 10 minutes, and the centrifuged supernatant was filtered through a 200-mesh screen, and then concentrated by heating at low temperature until the protein concentration in the supernatant reached 30%.

[0031] (2) Add 5% of rice starch, 10% of vegetable oil, 2% of salt and 2% of white granulated sugar to the protein solution finally obtained in step (1). The mixture is heated by microwaves to ripen raw materials such as protein and starch and produce aroma. The percentage described in this step is that ...

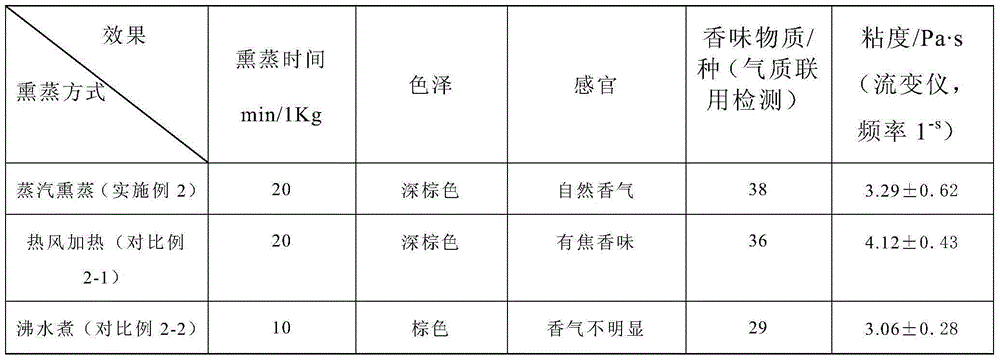

Embodiment 2

[0035] A preparation method of protein seasoning sauce, comprising the following steps:

[0036] (1) The high-temperature soybean meal is crushed into powder, 5 times the mass of purified water is added, and stirred evenly to obtain a soybean meal powder solution. Alkaline protease was added to the soybean meal powder solution, and placed in a 1.5kw ultrasonic wave for 20 minutes. The solution was placed in a constant temperature centrifuge at 20°C, centrifuged at 5000 rpm for 10 minutes, and the centrifuged supernatant was filtered through a 200-mesh screen, and then concentrated by heating at low temperature until the protein concentration in the supernatant reached 40%.

[0037] (2) Add 15% of rice starch, 5% of vegetable oil, 4% of salt and 2% of white granulated sugar to the protein solution finally obtained in step (1). The mixture is heated by microwaves to ripen raw materials such as protein and starch and produce aroma. The percentage described in this step is that ...

Embodiment 3

[0041] A preparation method of protein seasoning sauce, comprising the following steps:

[0042] (1) The high-temperature soybean meal is crushed into powder, 5 times the mass of purified water is added, and stirred evenly to obtain a soybean meal powder solution. Alkaline protease was added to the soybean meal powder solution, and placed in a 1.5kw ultrasonic wave for 20 minutes. Place the solution in a constant temperature centrifuge at 20°C, centrifuge at 5000 rpm for 10 minutes, filter the centrifuged supernatant through a 200-mesh screen, and then conduct low-temperature heating and concentration until the protein concentration in the supernatant reaches 50%.

[0043] (2) Add 10% of rice starch, 8% of vegetable oil, 5% of salt and 2% of white granulated sugar to the protein solution finally obtained in step (1). The mixture is heated by microwaves to ripen raw materials such as protein and starch and produce aroma. The percentage described in this step is that each raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com