Soybean sauce brewing process

A soy sauce and process technology, applied in the field of soy sauce brewing technology, can solve the problems of insufficient product flavor, weak ability to produce free amino acids, singleness and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation plan

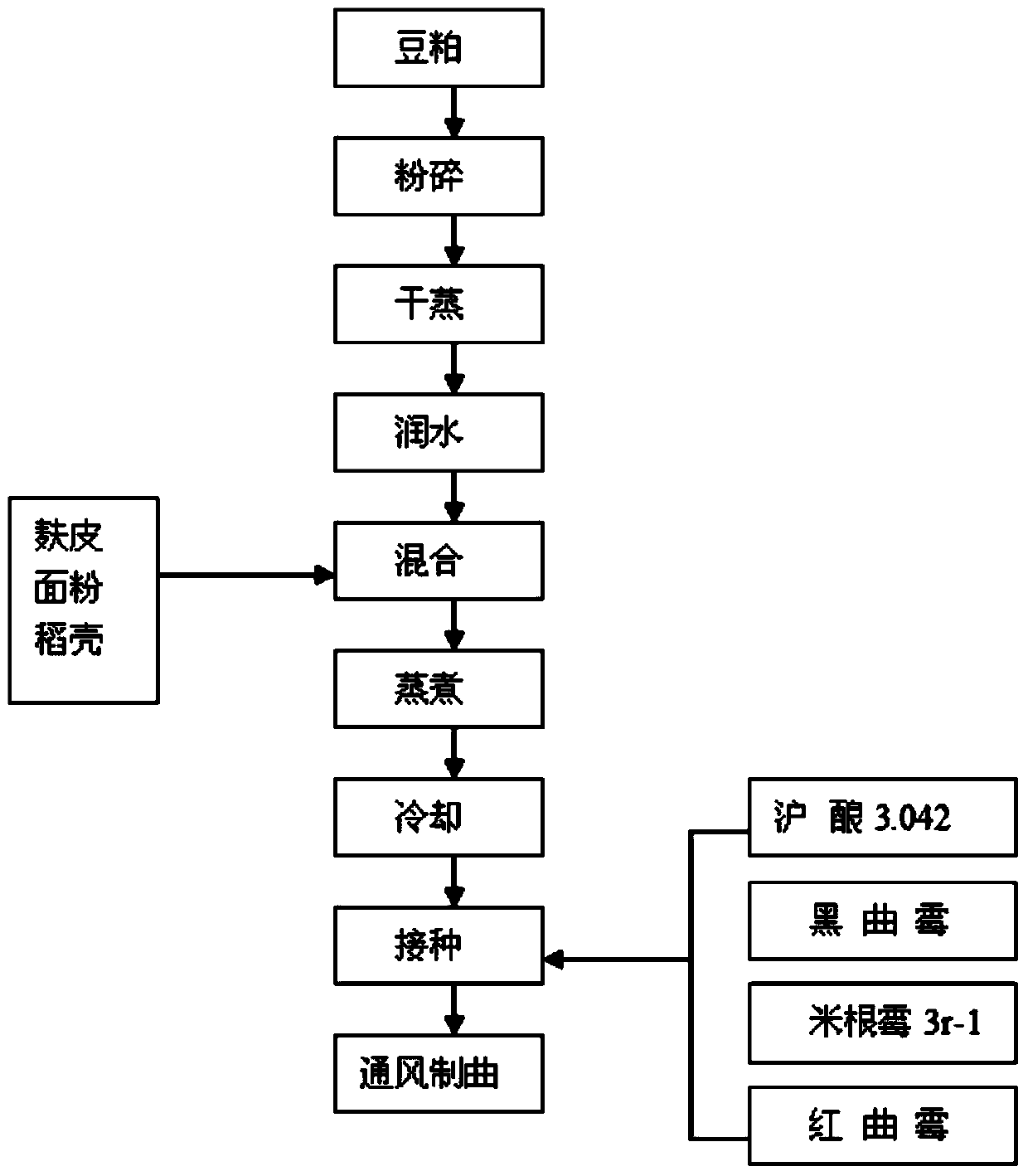

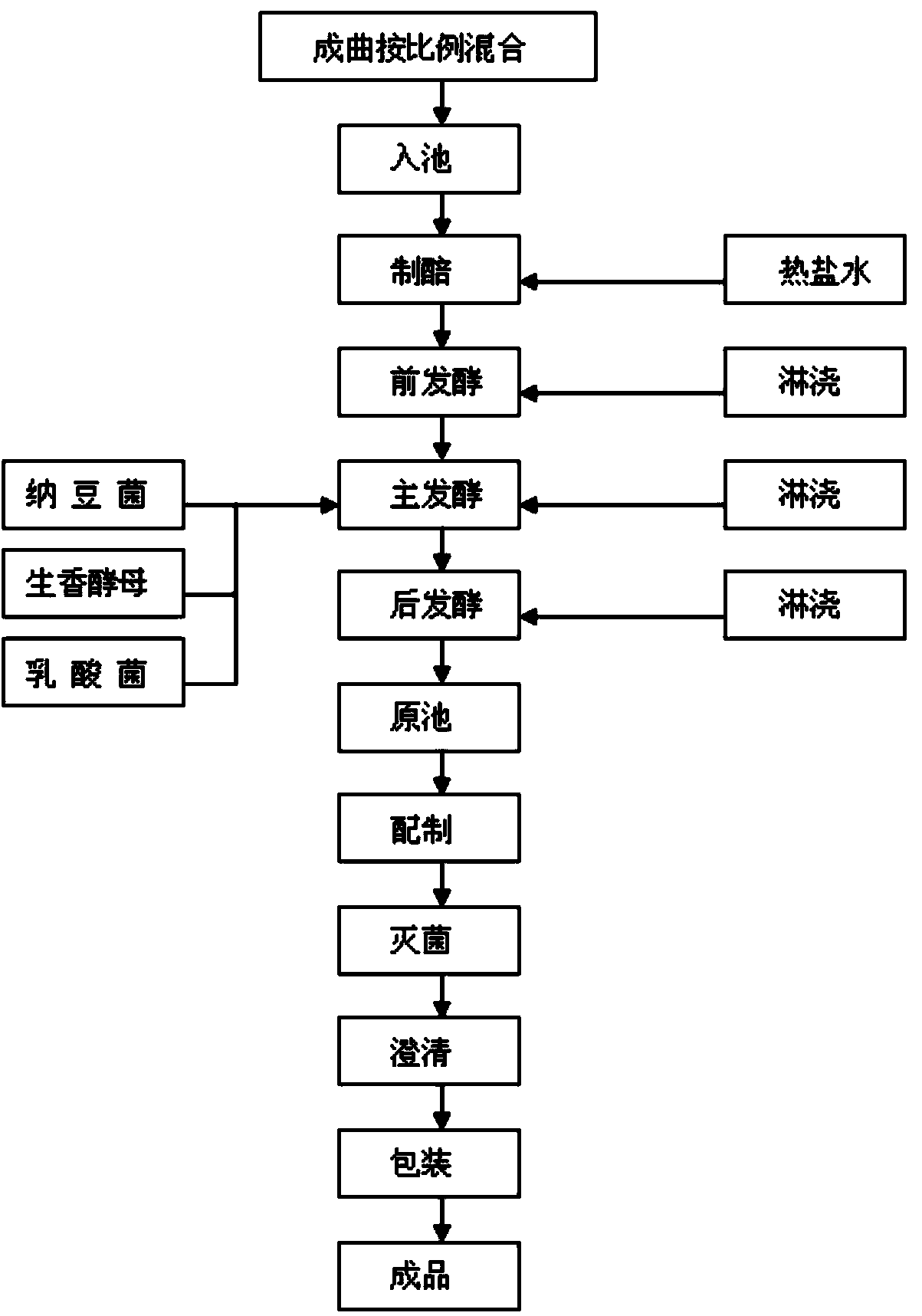

[0028] A soy sauce brewing process, comprising the following steps:

[0029] (1) Kind of song making: use the kind of song making machine to make the kind of song

[0030] a. Preparation of raw materials

[0031] Stir the flour and bran evenly at a mass ratio of 3:1 and put them on a plate with a thickness of 1.5-2.0cm;

[0032] b. Steam sterilization

[0033] After loading the koji material into the machine, adjust the upper limit of the koji material temperature to 130°C, open the steam valve, and when the pressure gauge rises to 0.1Mpa, close the steam valve, open the steam exhaust valve and the drain valve, and then close; reopen the steam valve, the pressure rises When the temperature reaches 0.15-0.18Mpa, the temperature is 120-122°C. After steaming for 25 minutes, open the exhaust valve and sewage valve to disinfect the inoculation nozzle;

[0034] c. Vaccination

[0035] Turn on the hydraulic ejector and vacuumize it to cool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com