Hand-push type hedge shearing machine

A hedge trimmer, hand-push technology, applied to hedge trimming equipment, etc., can solve the problems of increasing labor intensity of workers, restricting work efficiency, and difficulty in realization, and achieves flexible and convenient adjustment, good flatness, and simple and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings.

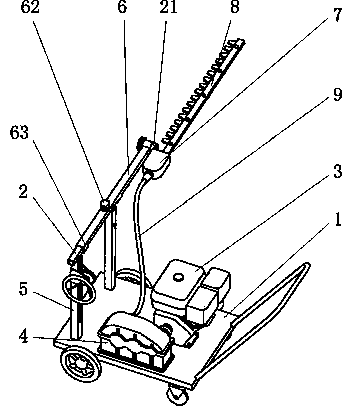

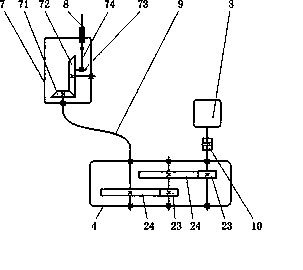

[0027] Such as figure 1 As shown, a kind of hand-push hedge trimmer of the present invention comprises cart 1, liftable support frame 2, and the gasoline engine 3 that is installed on the cart 1, reduction box 4 and fixed support frame 5, and described fixed The support frame 5 includes two steel pipes vertically installed on the surface of the trolley 1, and the liftable support frame 2 includes two vertical steel pipes 21 and a beam 22 connected to the top of the vertical steel pipes 21, and the vertical steel pipes 21 are respectively inserted and fixed Among the two steel pipes of the supporting frame 5, the crossbeam 22 is covered with a cantilever beam 6 that can move relative to the crossbeam 22. The overhang beam 6 is connected with an angle adjustment device, and the power conversion box 7 is connected through the angle adjustment dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com