SCR treatement of engine exhaust gases using temperature control

A technology of exhaust gas treatment and internal combustion engine, applied in the direction of exhaust gas treatment, electronic control of exhaust gas treatment device, diagnostic device of exhaust gas treatment device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

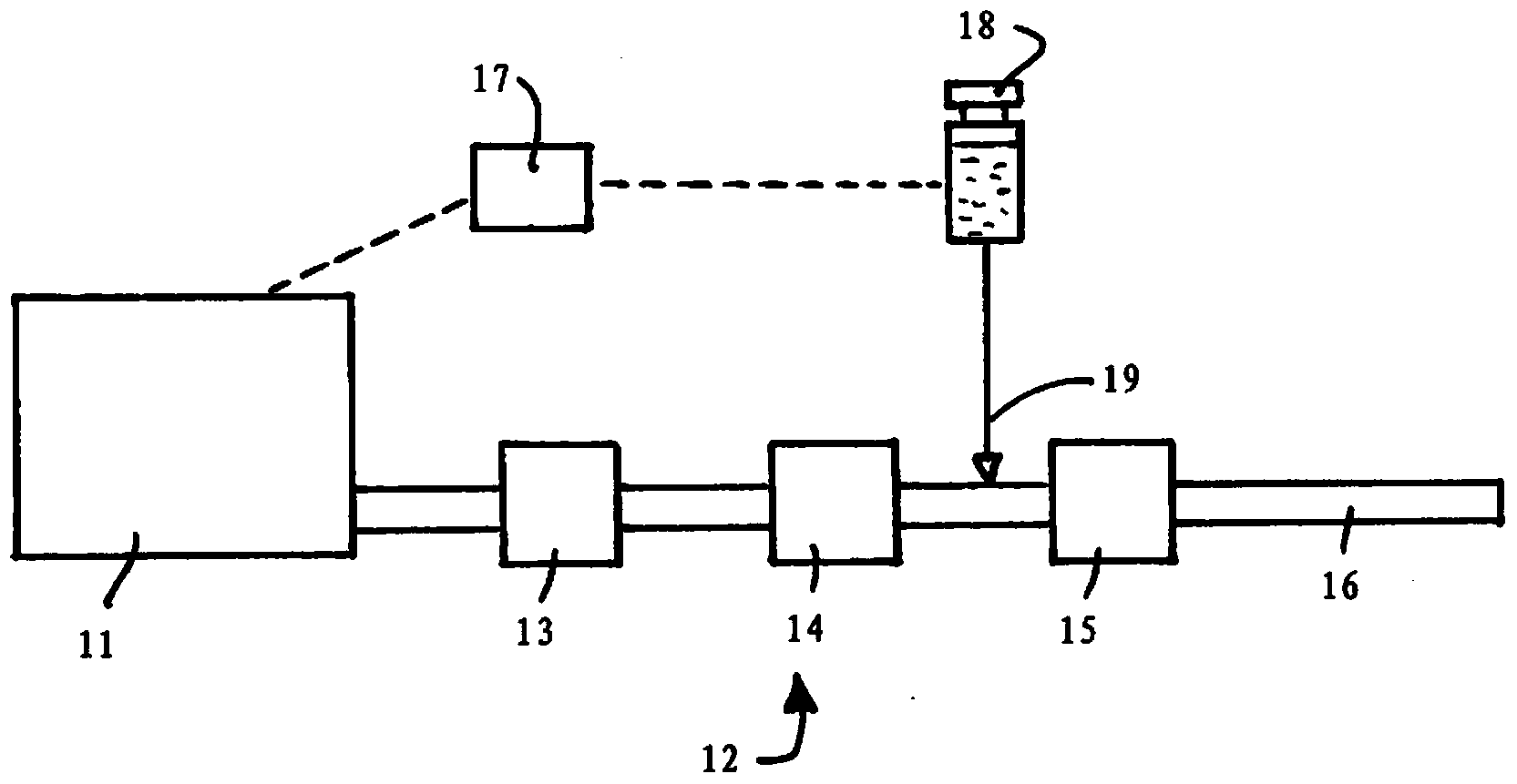

[0023] refer to figure 1 A diesel internal combustion engine 11 has an exhaust tract or system 12 comprising a diesel oxidation catalyst (DOC) 13 , a diesel particulate filter (DPF) 14 and a catalyst 15 for selective catalytic reduction. The exhaust duct ends with an open tailpipe 16 .

[0024] An engine management system (EMS) 17 electronically controls the operation of the engine, particularly the fueling of the engine, based on programmed information, real-time monitoring, and driver demand. Such engine management systems are well known and need not be further described here.

[0025] A container 18 of liquid urea is provided for periodic dosing of the exhaust tract as indicated by arrow 19 under the control of the EMS 17; as described above, the urea mixes with the exhaust gas to produce ammonia, which supplements the SCR catalyzed by the ammonia device. The mixing takes place in the region of the exhaust tract where urea is supplied, referred to herein as the make-up r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com