A cutting tool that can control the cutting depth

A technology of cutting depth and cutting tool, which is applied in the direction of dismantling/armouring cable equipment, etc., can solve the problems of high force control requirements for production personnel, obvious peeling and cutting lines on the surface, and unsatisfactory results, so as to eliminate production quality problems, surface Smooth and improve the effect of electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0017] The specific embodiment: the specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

Embodiment

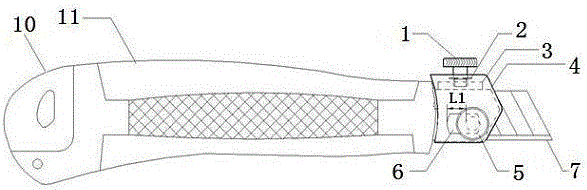

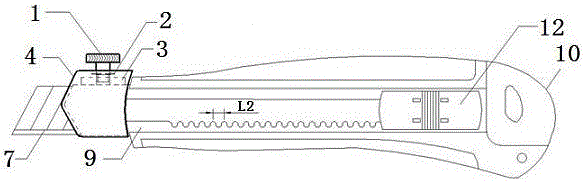

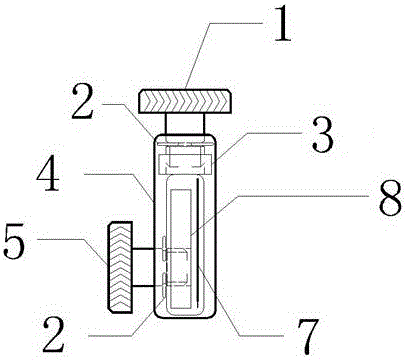

[0018] Embodiment: a kind of cutter that can control depth of cut (referring to Figure 1-Figure 3 ), which includes a knife handle 11, the rear end of the knife handle 11 is provided with a folder 10, the knife handle 11 is provided with a fixed knife rest 9, and the fixed knife rest 9 is provided with evenly distributed positioning teeth 13, and the fixed knife rest 9 A blade 7 is arranged inside, and the rear end of the blade 7 is connected with a fixed lock 12 . The front end of the fixed knife rest 9 is provided with a cutting depth control device, which is composed of a movable knife rest 4, a blade pressing plate 8, a blade fixing screw 5, a movable knife rest pressing plate 3, a movable knife rest fixing screw 1, and a spring clip 2. , the movable knife rest 4 is set outside the fixed knife rest 9, the movable knife rest 4 is provided with a movable knife rest moving groove 6, the movable knife rest 4 is provided with a blade pressure plate 8, and the blade fixing scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com