Electrolyte vacuum stirring bubble-removal device with self-cleaning function

A technology of vacuum stirring and automatic cleaning, which is used in the manufacture of electrical components, non-aqueous electrolyte batteries, and electrolyte batteries, etc. It can solve the problems of unstable injection accuracy, poor equipment injection process, and unsatisfactory treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

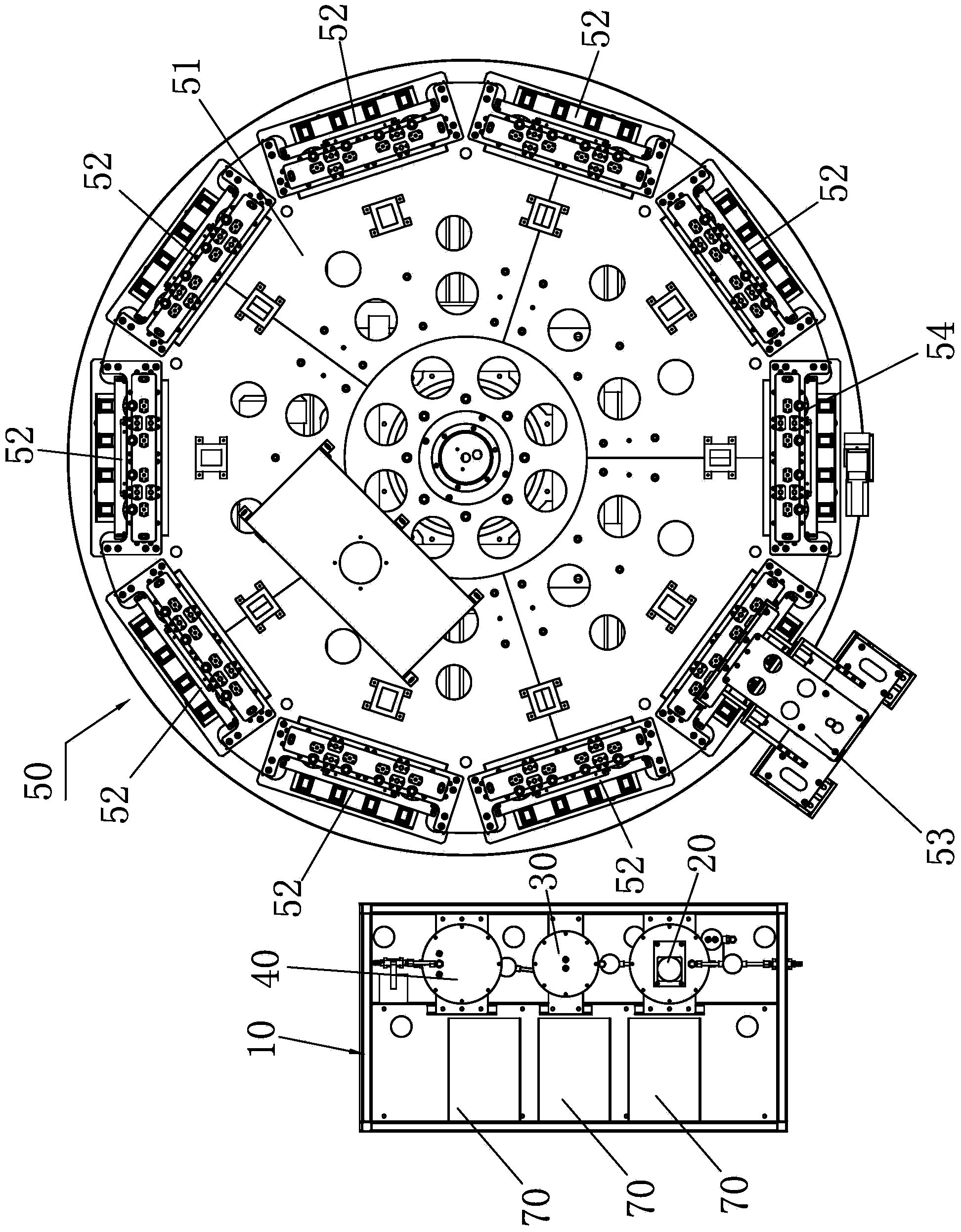

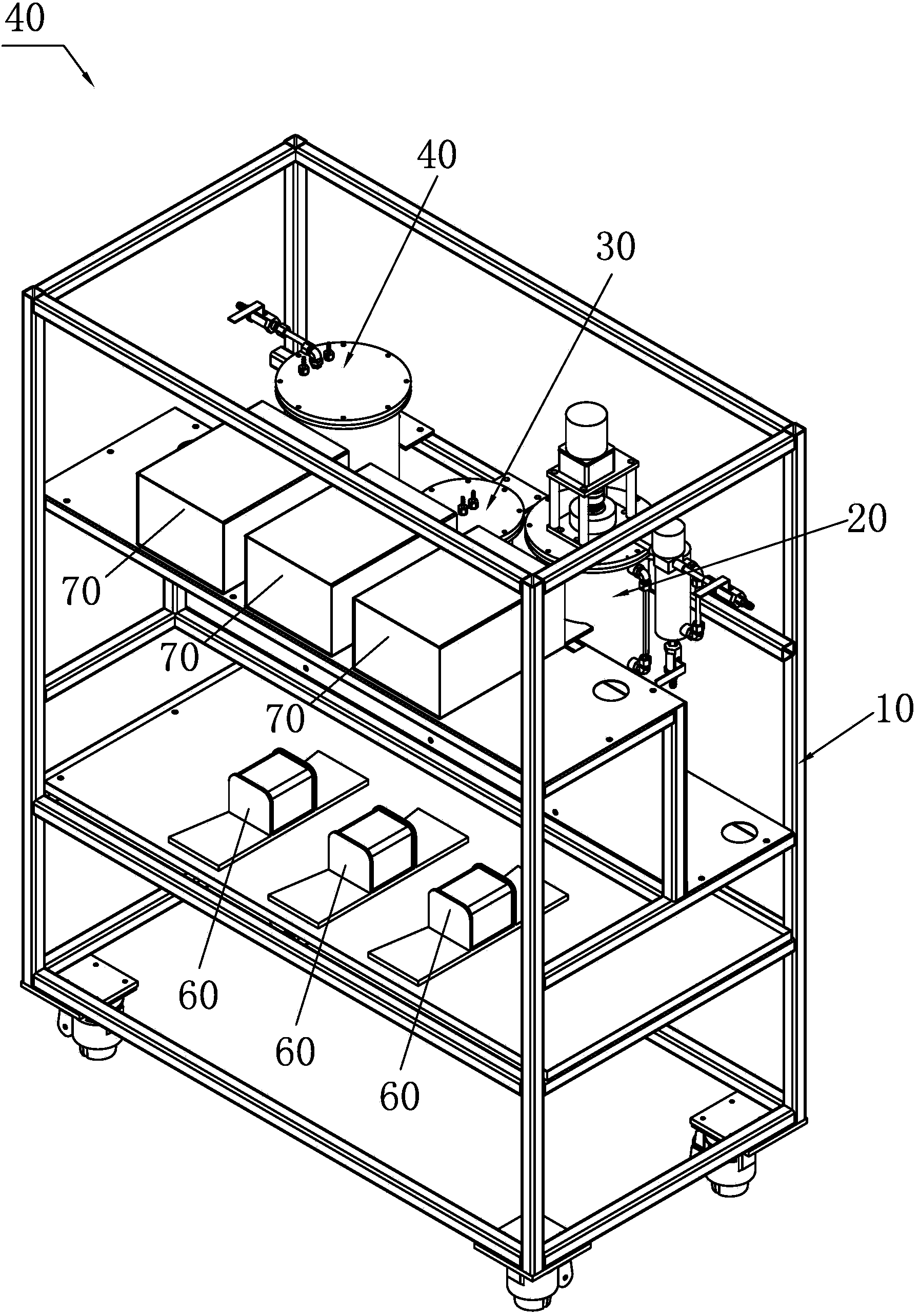

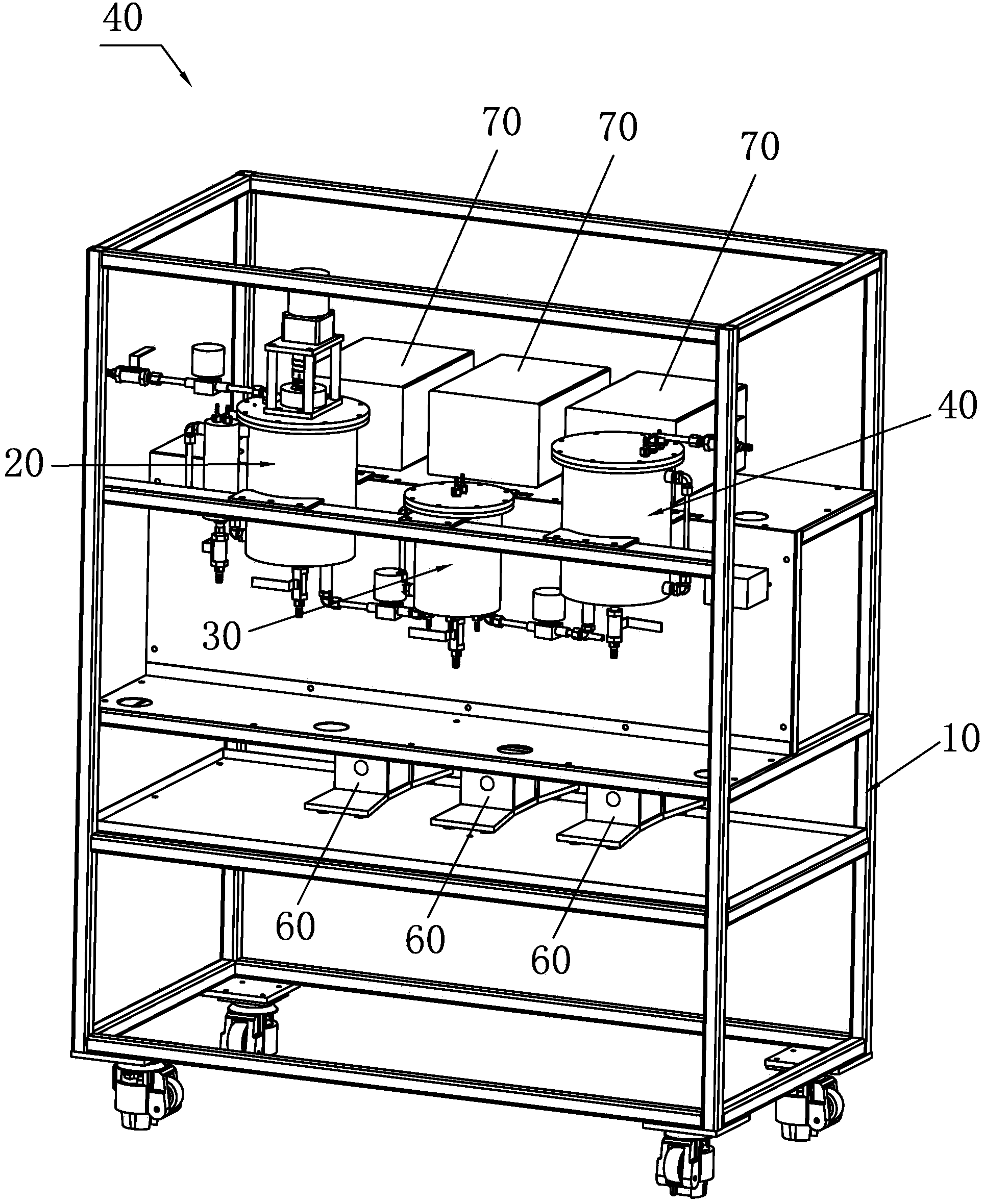

[0042] Please refer to Figure 1 to Figure 5 As shown, it has shown the specific structure of the preferred embodiment of the present invention, the electrolytic solution vacuum agitation degassing device with automatic cleaning function includes a main controller (not shown in the figure), a vacuum agitation device 20, The liquid storage device 30, the automatic cleaning device 40 and the liquid injection device 50 are equipped with a liquid injection pump 60 and a liquid injection pump 60 for controlling the liquid injection frequency and the liquid injection volume for the liquid storage device 30 toward the liquid injection device. pump controller 70 .

[0043] Wherein, the vacuum stirring device 20 includes an electrolyte degassing barrel 21, a vacuum stirring blade 22 and a vacuum stirring motor 23 for driving the vacuum stirring blade 22, the vacuum stirring motor 23 is located above the electrolyte debubbling barrel 21, the vacuum The stirring blade 22 is located insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com