Filling system of pressure differential liquefied natural gas filling station and method thereof

A technology of liquefied natural gas and filling system, which is applied in the field of liquefied natural gas filling facilities, can solve the problems of long time liquefied natural gas, increased BOG generation, easy generation of more BOG, etc., and achieves low daily operation cost and BOG generation. volume reduction, the effect of reducing flash steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

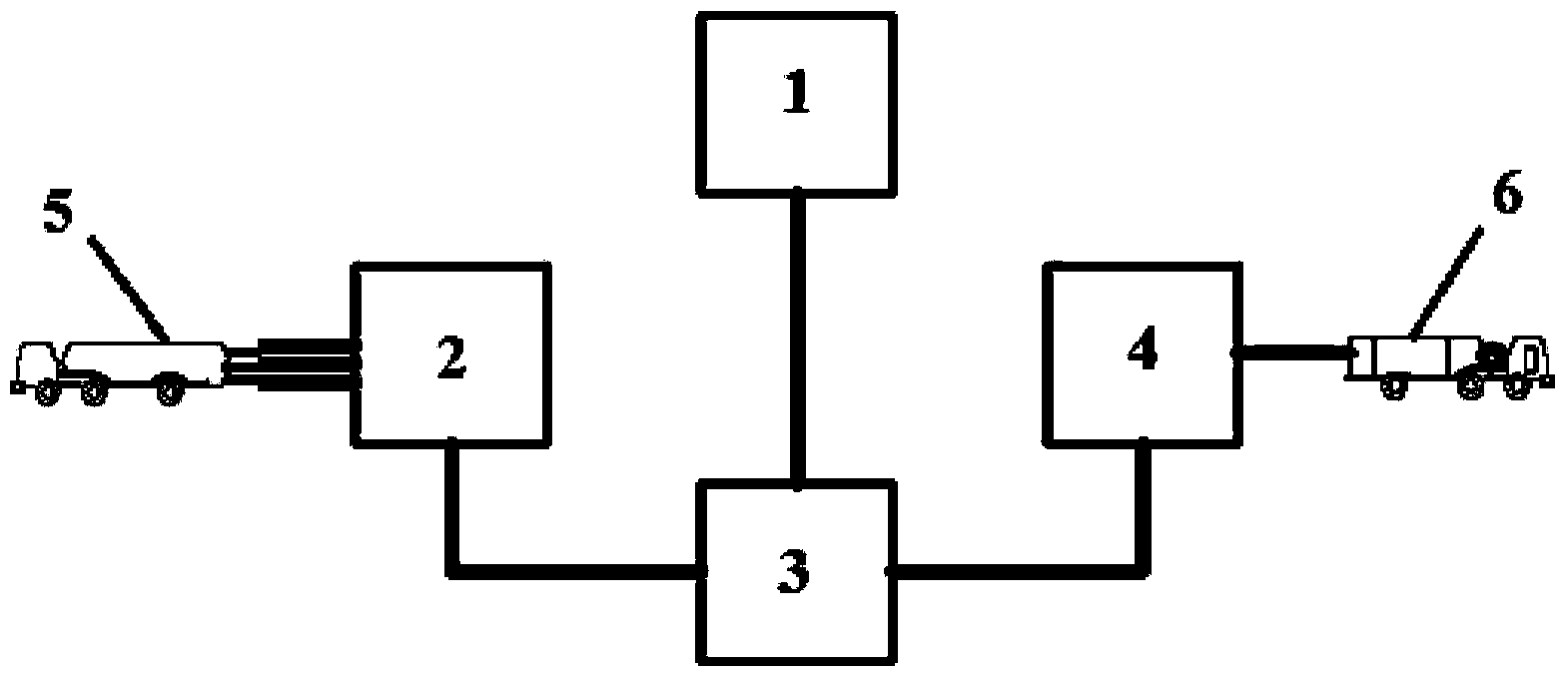

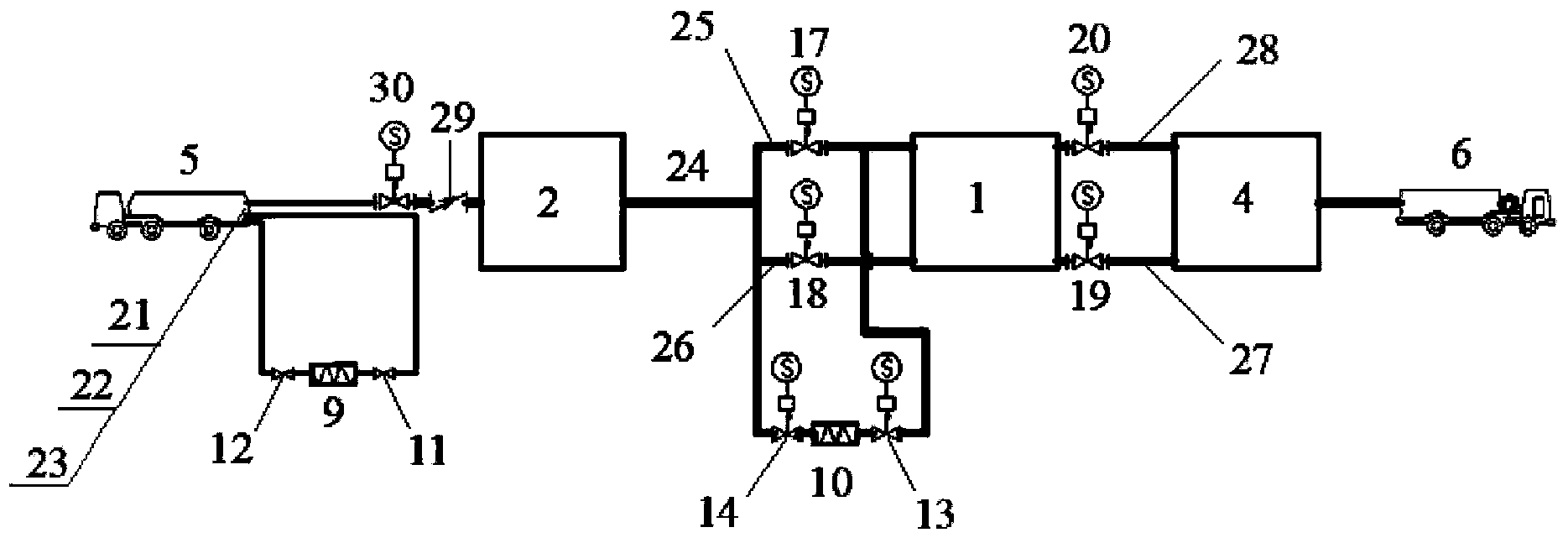

[0037] Such as figure 2 The pressure differential LNG refueling station filling system shown includes storage tank system 1, unloading system 2, gas filling system 4 and valve components, and unloading system 2 is installed on storage tank system 1 and the tank car of the gas filling station 5; the gas filling system 4 is set between the storage tank system 1 and the gas vehicle 6 to be filled.

[0038] The valve assembly includes the valves on both sides of the unloading carburetor 9, the pneumatic valve 17 of the upper liquid inlet pipe, the pneumatic valve 18 of the lower liquid inlet pipe, the pneumatic valve 19 of the liquid outlet pipe, the pneumatic valve 20 of the air return pipe, and the pneumatic valves on the front and rear sides of the booster carburetor 10 ,in:

[0039] The tank car 5 is provided with an unloading port 21, a gas phase port 22 and a booster port 23, an unloading carburetor 9 is arranged between the gas phase port 22 and the booster port 23, and a f...

Embodiment 2

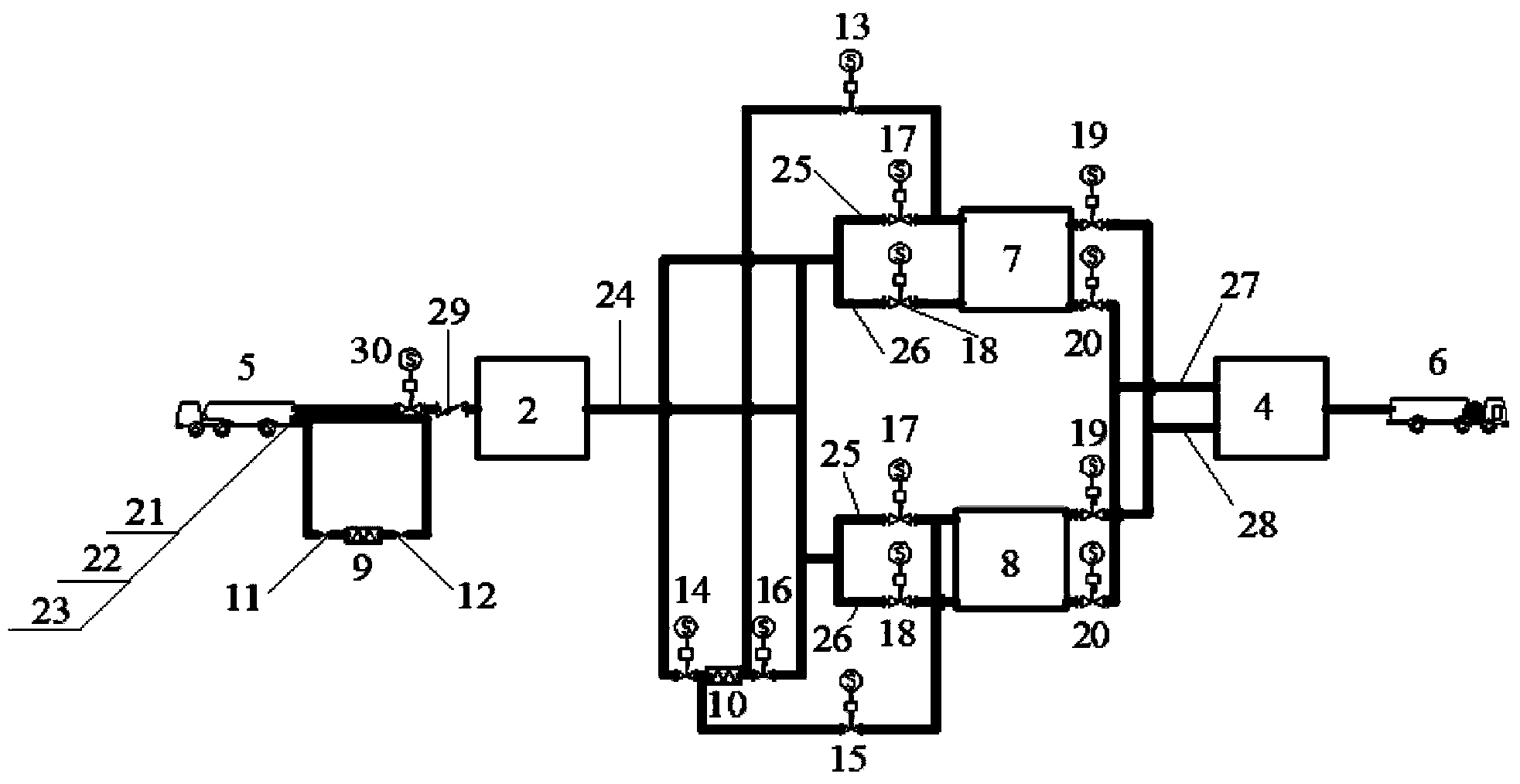

[0053] Such as image 3 As shown in the filling system of the differential pressure liquefied natural gas filling station, the storage tank system 1 of this embodiment adds a storage tank on the basis of embodiment 1, that is, two storage tanks (storage tank A7 or storage tank B8), one of them is used as a filling tank, and the other is used as a gas return tank for a gas cylinder of a gas vehicle. At the same time, the two tanks can be switched. When the storage tank A7 is used as a filling tank, the storage tank B8 is used as a return tank. Gas storage tank, after the LNG in storage tank A7 is filled, the system is converted to storage tank B8 for filling, and storage tank A7 is converted to a gas return tank; it is guaranteed that LNG fuel can be filled while unloading, without affecting daily operations .

[0054] At this time, a booster carburetor 10 is arranged between the storage tank A7 and the storage tank B8, and two sets of pneumatic valve groups are respectively a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com