Preparation method and properties of series of organometallic host-guest composite materials

A technology of metal-organic and composite materials, applied in the field of material chemistry, can solve the problems of instability, damage, and harsh conditions of materials with high specific surface area, and achieve the effects of easy operation, mild processing conditions, and simple characterization methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment the present invention is described in further detail.

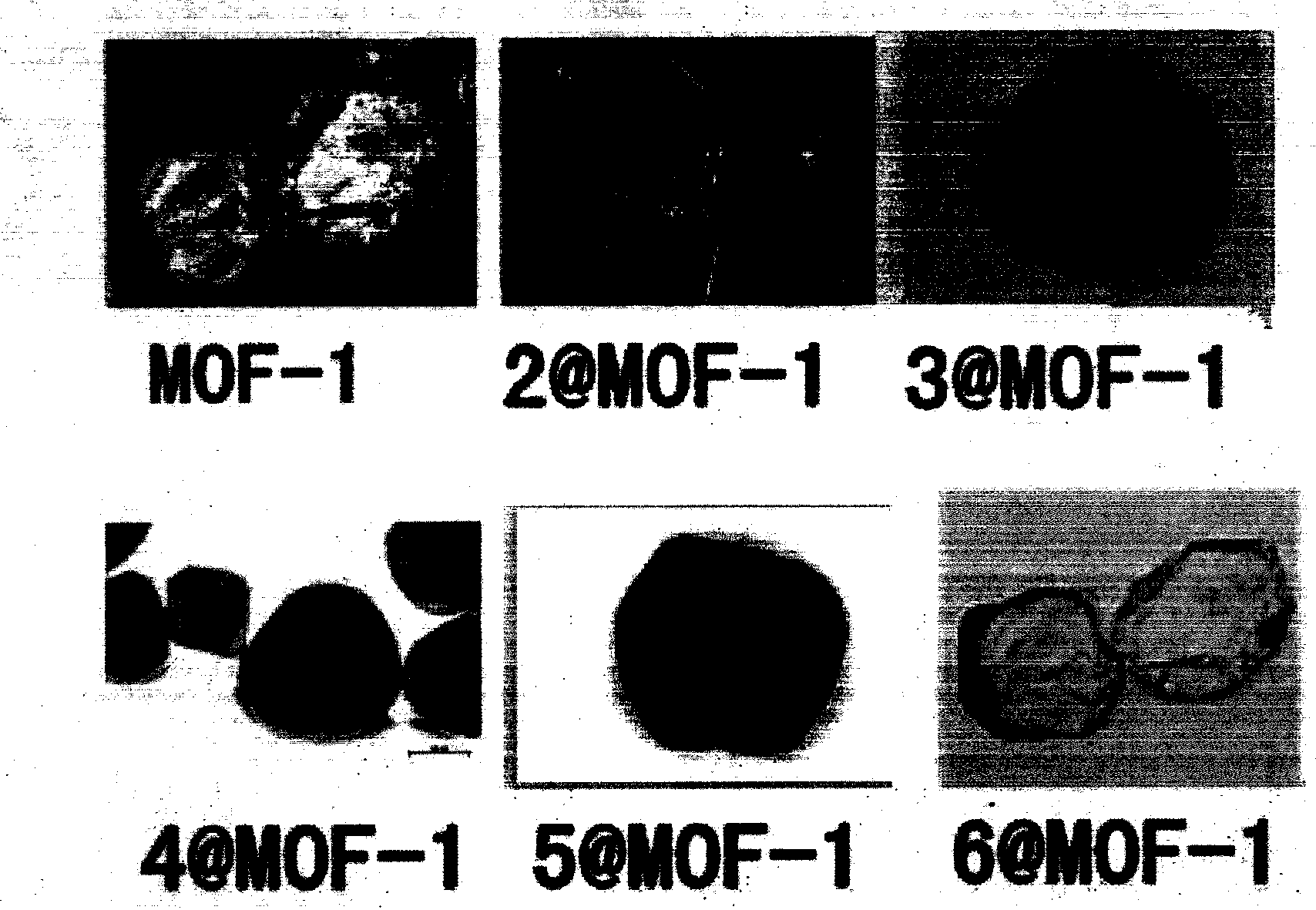

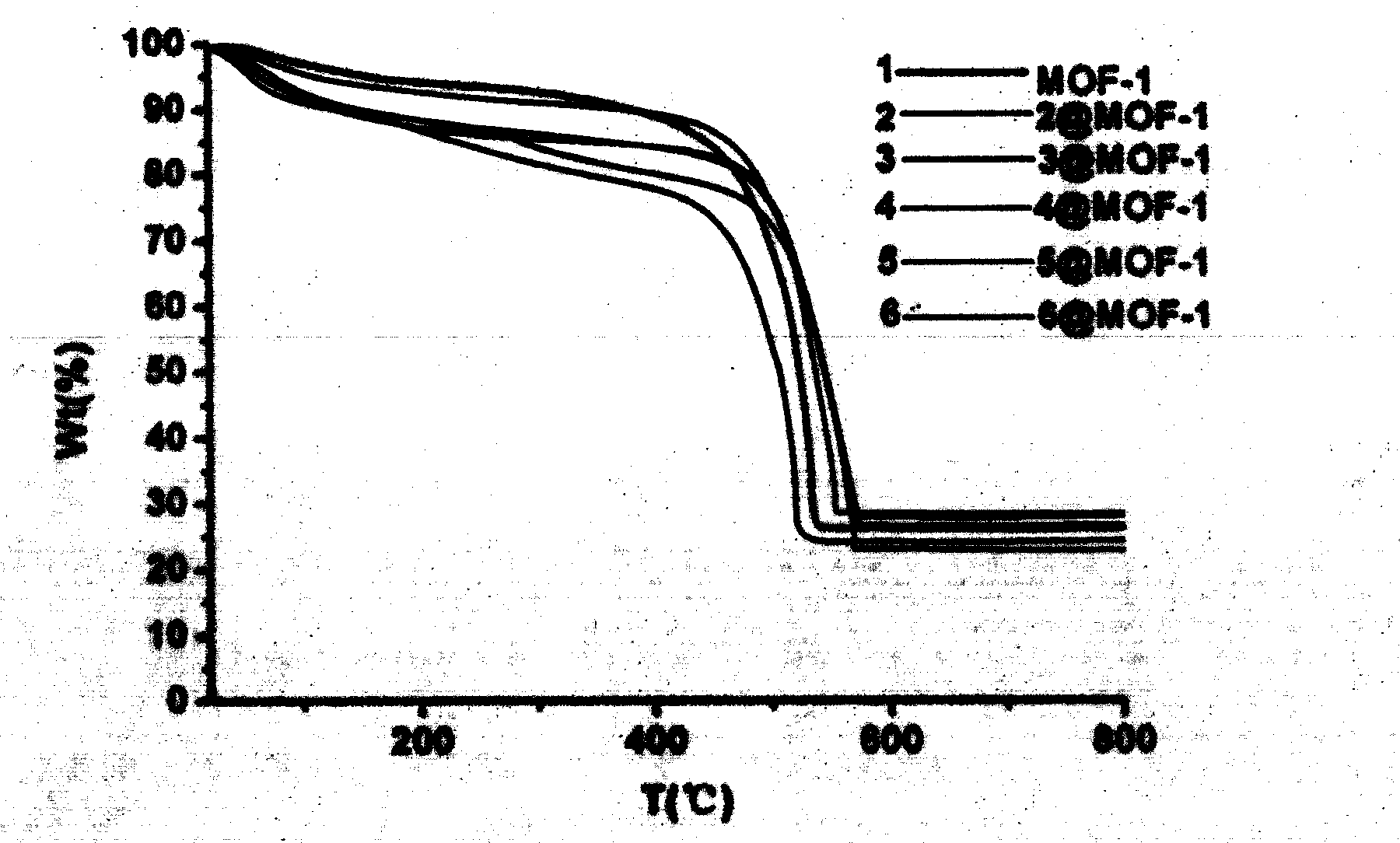

[0018] Using the large-porous material of the metal that has been reported in the literature as a raw material, divide it into several parts with an amount of 9mg-15mg, pretreat it with 5-10ml methanol for 3-5 days, dry under reduced pressure to remove methanol molecules, and then A certain amount of guest molecules tetrathiafulvalene (TTF), 7,7,8,8-tetracyanoquinoline methane (TCNQ), 1,1'-dimethyl-4,4'-dichloride Bipyridinium (MV 2+ ), N, N, N, N-tetramethyl-p-phenylenediamine (TMPD) and azobenzene (ABZ) and the processed raw material were put into 5~10ml dichloromethane for 10-20 days, to the obtained material Perform reduced pressure drying treatment for 1-2 days to remove residual guest molecules on the surface of the material, and observe in the electron microscope that it is immersed in TTF, TCNQ, MV 2+ , TMPD, and the colorless materials of ABZ become red, green, gray, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com