Flame-retardant and slow-rebounded ethylene-propylene-diene-terpolymer rubber porous foaming material and preparation method thereof

A technology of EPDM and foaming materials, applied in the field of foaming materials, can solve the problems of large compression deformation, poor flame retardant effect, limited use range, etc., and achieves strong shock absorption, small compression deformation, and simple and easy preparation method. row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: A preparation method of a flame-retardant slow-rebound EPDM rubber open-cell foam material is as follows:

[0054] (1) Internal mixing: first put 100 parts of EPDM rubber, 70 parts of butyl rubber, 10 parts of carbon black, and 10 parts of petroleum resin into the internal mixer for 5 minutes under pressure, and then add 3 parts of dispersant, 5 parts of flow agent, 5 parts of anti-aging agent, 10 parts of flame retardant, 10 parts of smoke suppressant, 50 parts of kaolin, 15 parts of foaming aid, 20 parts of foaming agent, 50 parts of processing oil, put into internal mixer and pressurize Knead for 15 minutes; finally, put 5 parts of accelerator and 6 parts of vulcanizing agent into the internal mixer and knead for 3 minutes under pressure to remove the glue. During mixing, the temperature in the internal mixer is controlled at 120°C.

[0055](2) Automatic thermal refining, hanging and parking: Put the mixed rubber into the open mill for thermal refining,...

Embodiment 2

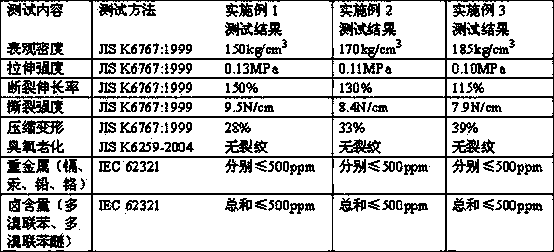

[0060] The preparation method of embodiment 2 and embodiment 3 is the same as embodiment 1, and the only difference is that the weight ratio of each raw material is different, and the ratio of raw material weight parts in embodiment 1-3 is shown in Table 1:

[0061]

[0062] Table 1, the proportioning table of each raw material weight part of embodiment 1-3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com