Exterior wall, slope and flat roofing insulation board manufacturing method and insulation board

An external wall insulation board and a technology for its production method, which are applied in the field of building construction materials, can solve the problems of low thermal insulation performance and poor hydrophobic performance of the thermal insulation layer, and achieve the effects of good moisture drainage and waterproof, non-waterproof, and good fire prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The invention utilizes high-quality thermal insulation materials and thermal insulation materials to effectively compound into a paste, and its mechanism of action is to skillfully integrate contradictory functions into one organic whole.

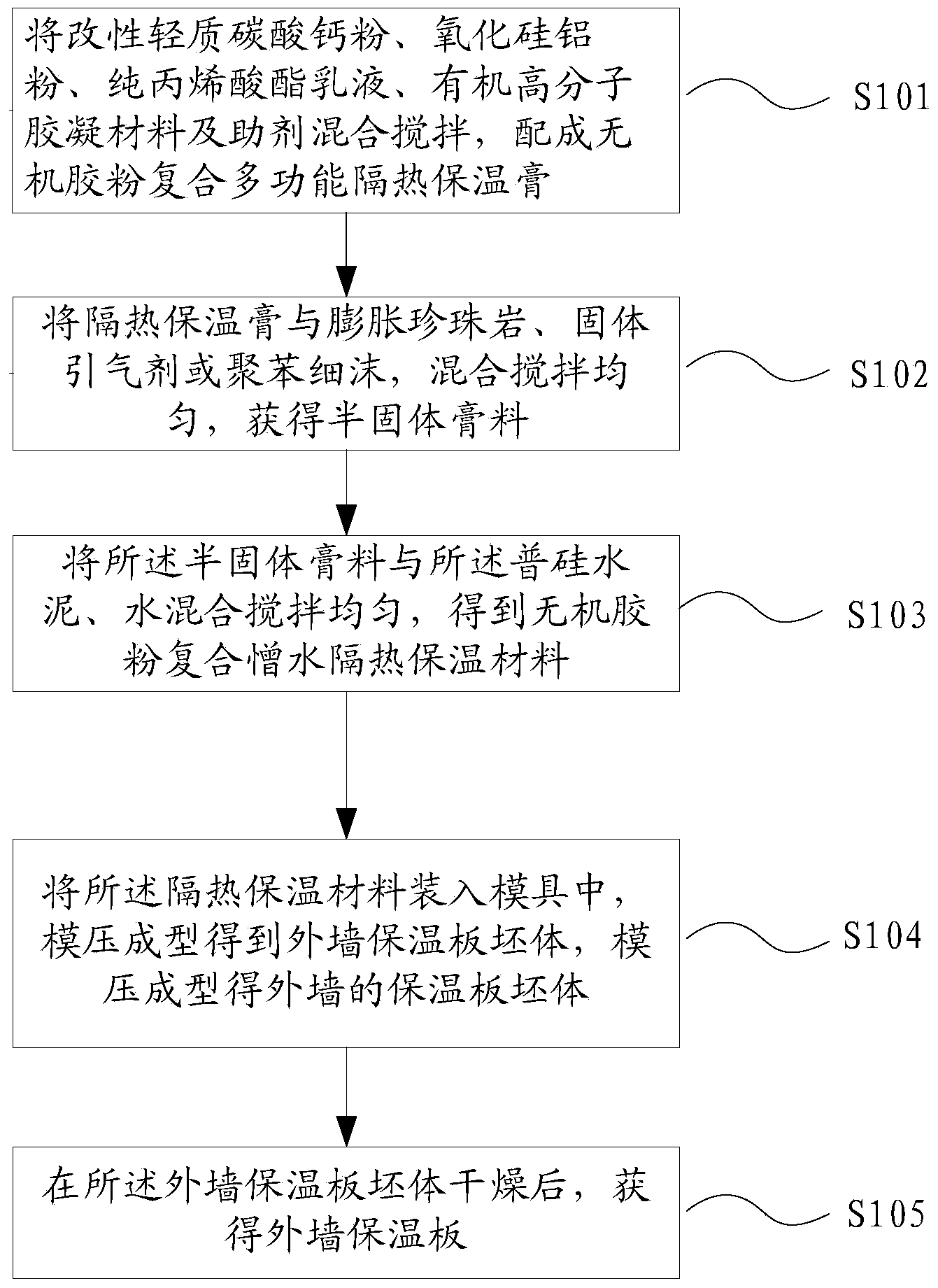

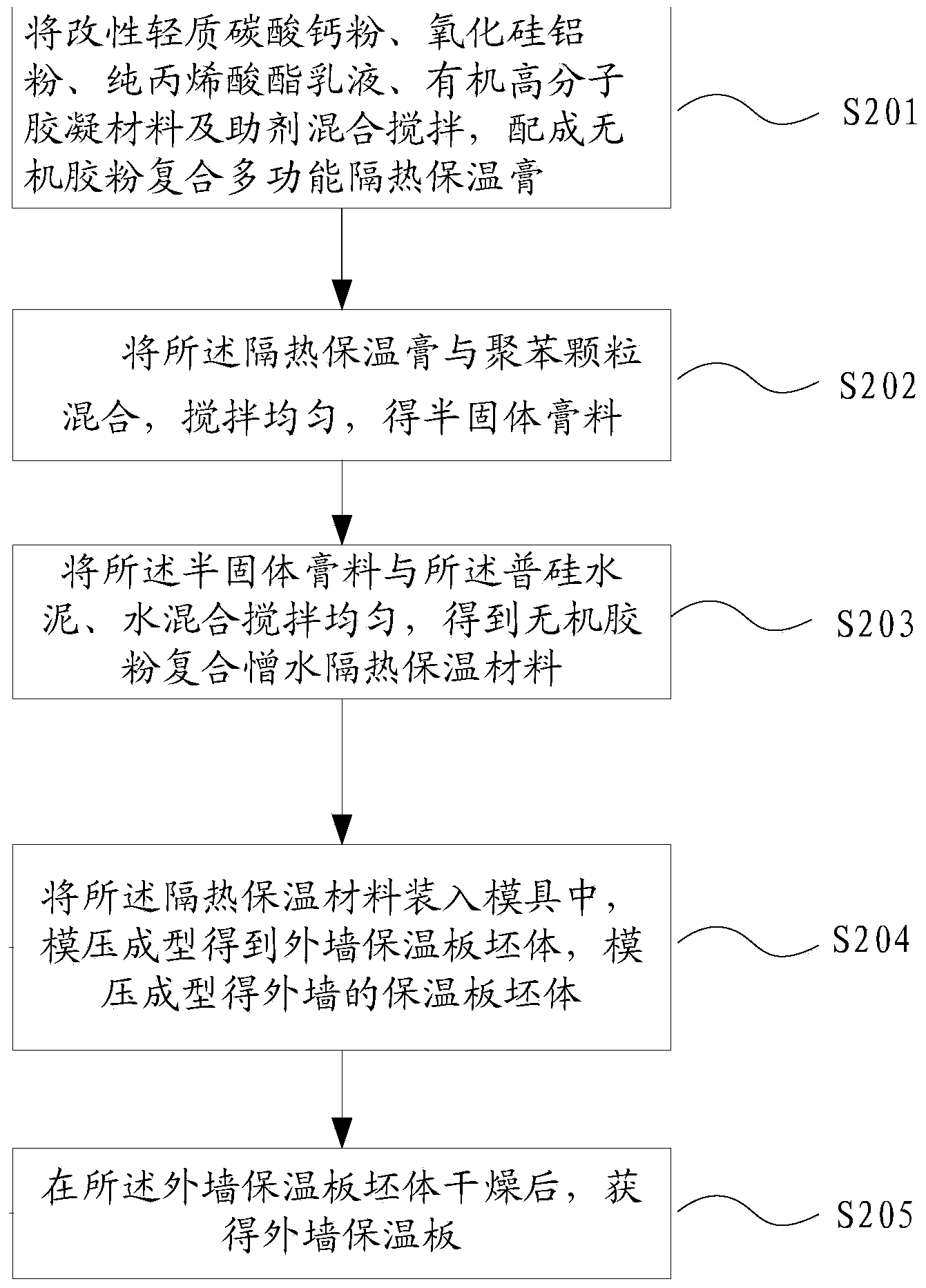

[0034] In one embodiment of the present invention, the manufacturing method of the external wall insulation board comprises the following steps:

[0035] Step S101, mixing and stirring modified light calcium carbonate powder, aluminum silica powder, pure acrylate emulsion, organic polymer gelling material and additives to prepare inorganic rubber powder composite multifunctional thermal insulation paste.

[0036] In this step, the organic polymer gelling material includes alginate, hydroxypropyl methylcellulose water retention agent and hydroxypropyl starch ether thickener, and the auxiliary agent includes polypropylene fiber and preservative. Among them, the weight percentage (%) of each component is: modified light calcium carbonat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com