Sludge treatment method

A sludge treatment and sludge technology, applied in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the problems such as the overall technical route of sludge treatment and disposal in the country is not clear enough, and achieve the restoration of nature Flavor, soil improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

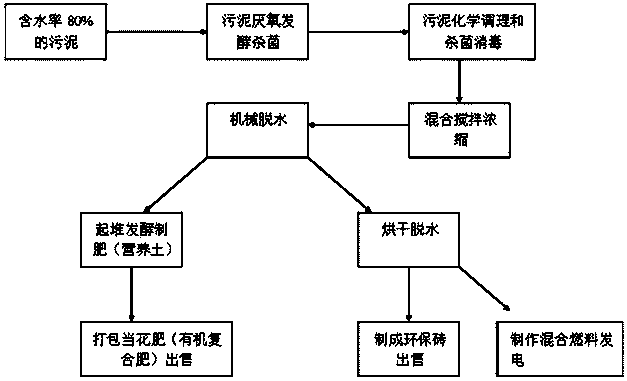

[0018] The present invention will be further explained below in conjunction with the drawings.

[0019] Such as figure 1 As shown, the sludge with a water content of 80% is stored in a sludge tank for anaerobic fermentation, and anaerobic fermentation is the waste that is stabilized by the metabolic activities of microorganisms under anaerobic conditions, accompanied by methane and CO 2 produce. The methane gas produced in this process is used as the main energy source for the drying of the sludge after dehydration. On the other hand, it can kill most of the harmful bacteria and viruses in the sludge. It can be stored for several days (mainly based on the amount of mud). Decide the storage time). Then use the sludge pump to pump the sludge into a circular stirring tank for chemical conditioning and sterilization. Add 4# additive to dehydrate the sludge for chemical conditioning. The 4# additive stabilizes the heavy metals and organics in the sludge. The effect of chemical treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com