Method for producing KCl from ground surface carnallite

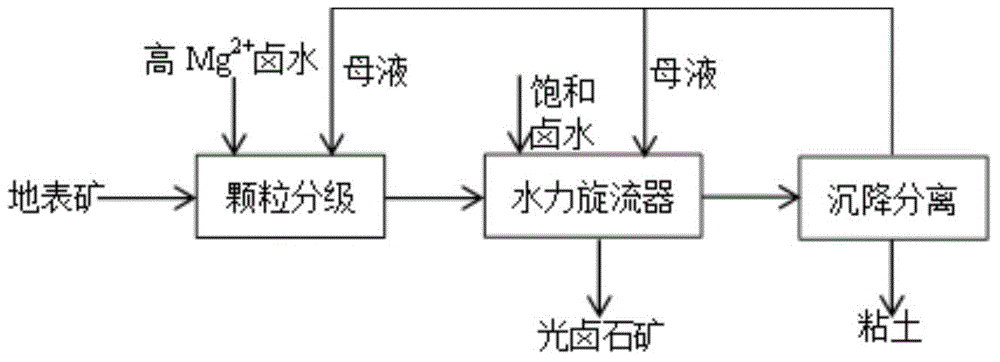

A carnallite mine and surface technology, which is applied in the direction of alkali metal chloride, etc., can solve the problems of high clay content, high clay surface carnallite mine being idle and unused, and no direct mining and utilization of mature technology, etc. The effect of adding amount, shortening the production process and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] According to the ore liquid ratio of 1:1.05, the surface carnallite ore and high Mg 2+ Brine (Mg 2+ The mass concentration is 7.0%) mixing, stirring at room temperature for 2.5h, the rotating speed is controlled at 350r / min, then the slurry is sent into the spiral particle classifier and the hydrocyclone successively, and the inlet pressure of the hydrocyclone is controlled to be 0.10~0.30Mpa , to complete the mineral conversion and desliming, the mineral composition is obtained as: K + 7.95%, Mg 2+ 6.12%, Cl - 35.57%, SO 4 2- 1.86%, Na + 7.71%, the carnallite ore and fresh water were stirred and decomposed by mass ratio 1:1.05 for 30min to obtain slurry, and the above-mentioned decomposed mother liquor was added according to the solid-to-liquid ratio of 1:2.5, and the flotation reagent (18 hydrochloric acid Amine), using two refining and sweeping procedures, to obtain KCl.

Embodiment 2

[0044] According to the ore liquid ratio of 1:1, the surface carnallite ore and high Mg 2+ Brine (Mg 2+ The mass concentration is 8.0%) mixing, stirring at room temperature for 3h, the rotating speed is controlled at 350r / min, then the slurry is sent into the spiral particle classifier and the hydrocyclone successively, and the inlet pressure of the hydrocyclone is controlled to be 0.10~0.30Mpa, Mineral conversion and desliming are completed, and the mineral composition is obtained as: K + 7.95%, Mg 2+ 6.12%, Cl-35.57%, SO 4 2- 1.86%, Na + 7.71%, the carnallite ore is ball milled to Taylor sieve 20 mesh sieve, then stirred and decomposed with fresh water at a mass ratio of 1:1.25 for 30 minutes to obtain a slurry, and the above-mentioned decomposed mother liquor is added according to a solid-to-liquid ratio of 1:2. t KCl proportional flotation agent (octadecylamine hydrochloride), using two refining and one sweeping procedures to obtain KCl.

Embodiment 3

[0046] According to the ore liquid ratio of 1:1.2, the surface carnallite ore and high Mg 2+ Brine (Mg 2+ The mass concentration is 9.0%) mixing, stirring at room temperature for 2.8h, the rotating speed is controlled at 380r / min, then the slurry is sent into the spiral particle classifier and the hydrocyclone successively, and the inlet pressure of the hydrocyclone is controlled to be 0.10~0.30Mpa , to complete the mineral conversion and desliming, the mineral composition is obtained as: K + 9.23%, Mg 2+ 6.23%, Cl - 35.48%, SO 4 2- 1.35%, Na + 6.45%, the carnallite ore is ball milled to Taylor sieve 20 mesh sieve, then stirred and decomposed with fresh water at a mass ratio of 1:1.15 for 30 minutes to obtain a slurry, and the above-mentioned decomposed mother liquor is added according to a solid-to-liquid ratio of 1:2.5, by 420g / t KCl proportional flotation agent (octadecylamine hydrochloride), using two refining and one sweeping procedures to obtain KCl.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com