A contour fillet automatic control deburring device

A deburring and filleting technology, applied in the direction of manufacturing tools, grinding feed movement, grinding workpiece support, etc., can solve the problems of low grinding accuracy, affect the use of workpieces, affect the accuracy of parts and use requirements, and achieve grinding accuracy High, prevent left and right tilt, uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

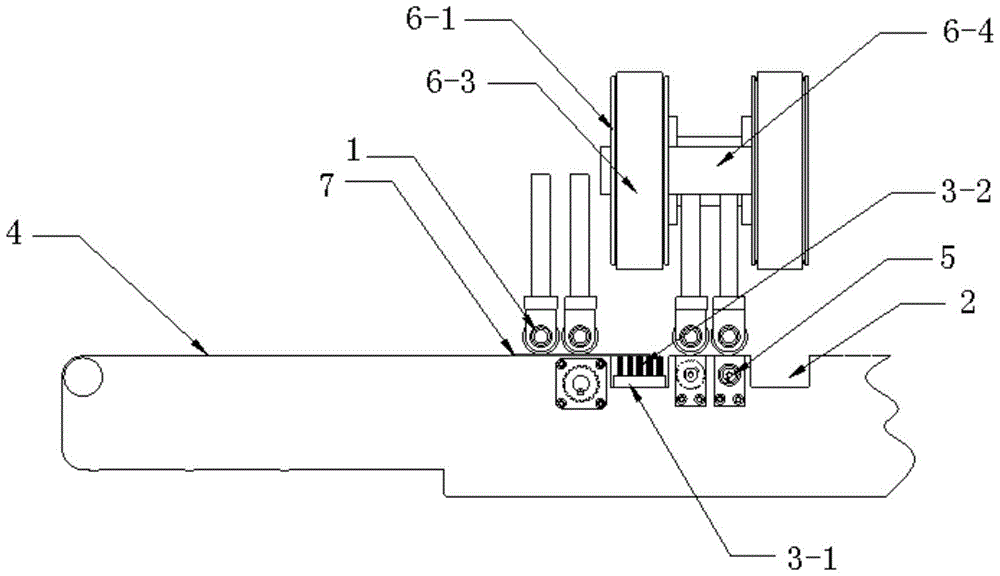

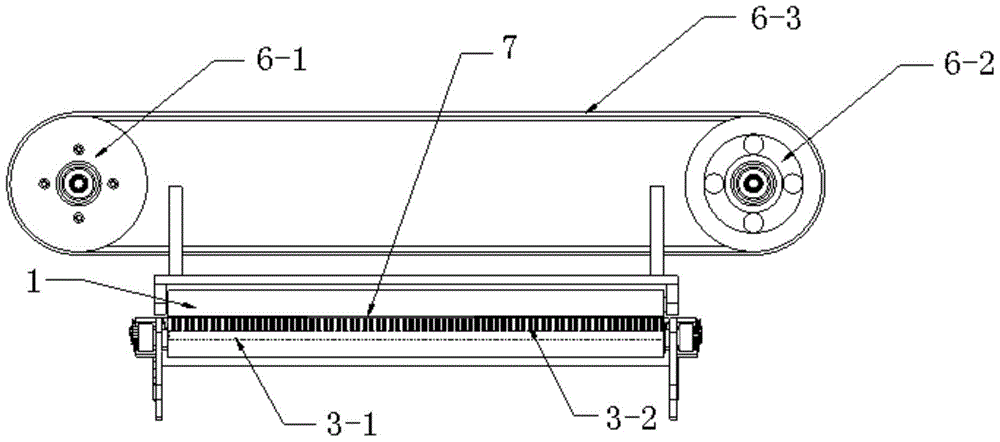

[0019] Example: refer to figure 1 , 2 As shown, a contour fillet automatic control deburring device includes a workpiece transmission mechanism and a burr grinding mechanism. roller wheel) and a grinding device corresponding to the rear side of each group of pressing roller device 1 and whose grinding direction is perpendicular to the conveying direction of the workpiece conveying mechanism. A strip-shaped grinding groove 2 is provided directly below each grinding device. At the same time, a support component is provided in the bar-shaped grinding groove 2 .

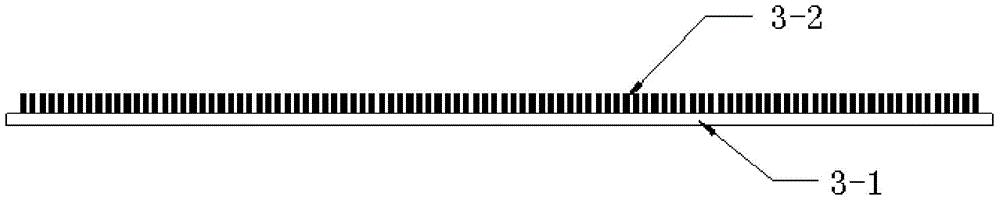

[0020] refer to image 3 As shown, the support member of the present invention includes a fixed base 3-1 located at the bottom of the bar-shaped grinding groove 2, and a support brush 3-2 evenly arranged on the fixed base 3-1, and the top of the support brush 3-2 is connected to the bar. The top of the grinding groove 2 is parallel to the top, and the support brush 3-2 cooperates with the grinding brush (not shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com