Medical gasket

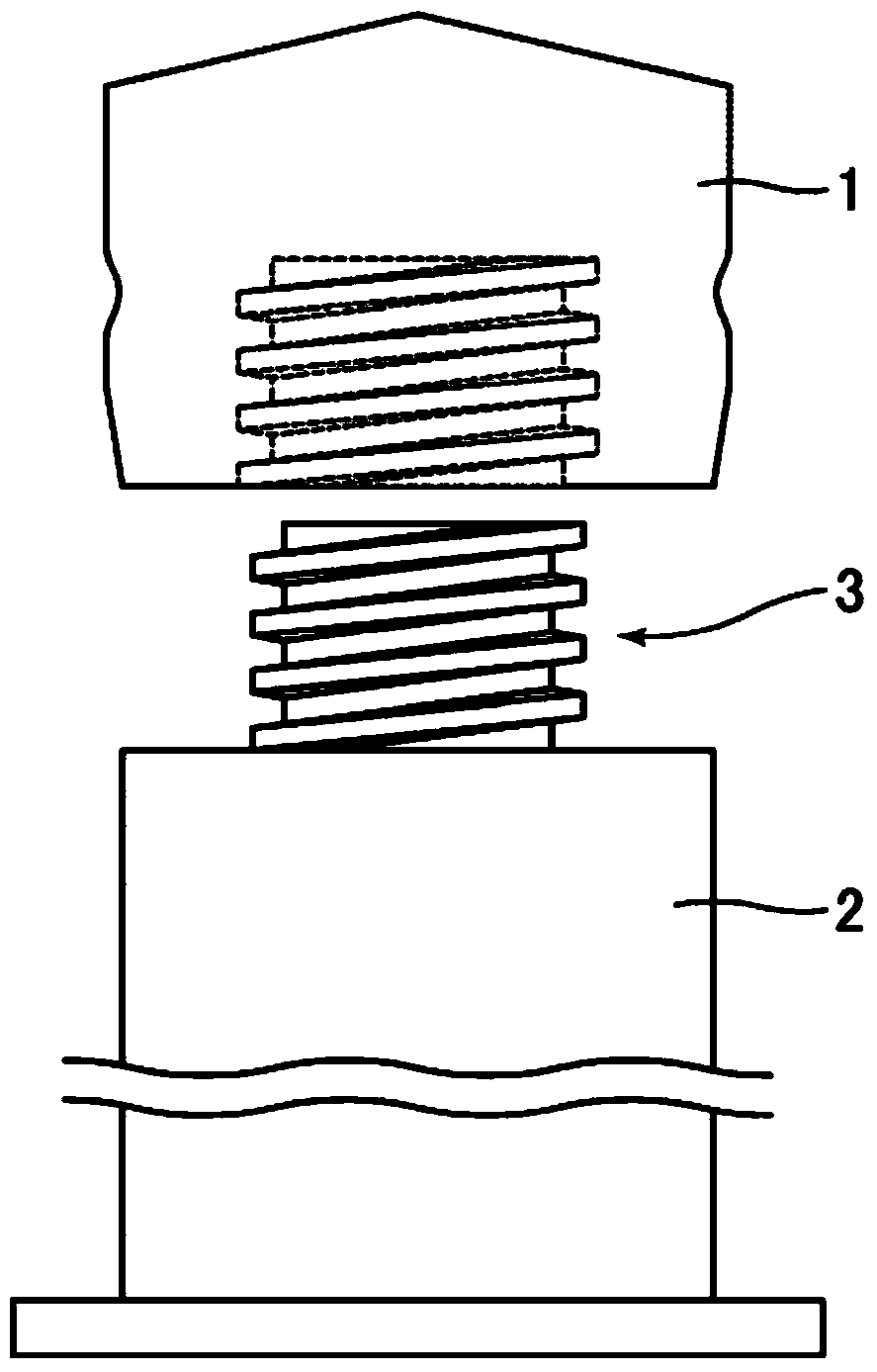

A sealing gasket and medical technology, applied in the direction of infusion sets, syringes, hypodermic injection equipment, etc., can solve the problems of increased friction between the sealing gasket and the syringe barrel, pressing in, difficult sealing gaskets, etc., and achieve the goal of reducing the fastening force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2 and comparative example 1

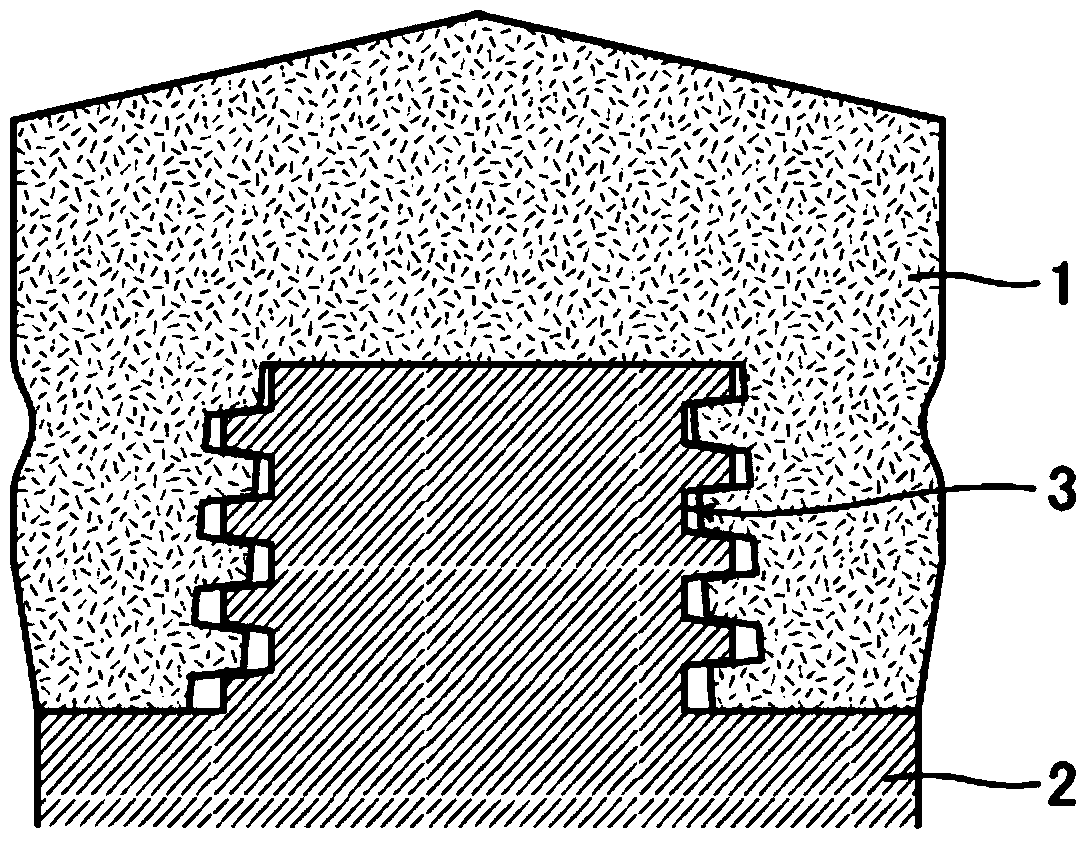

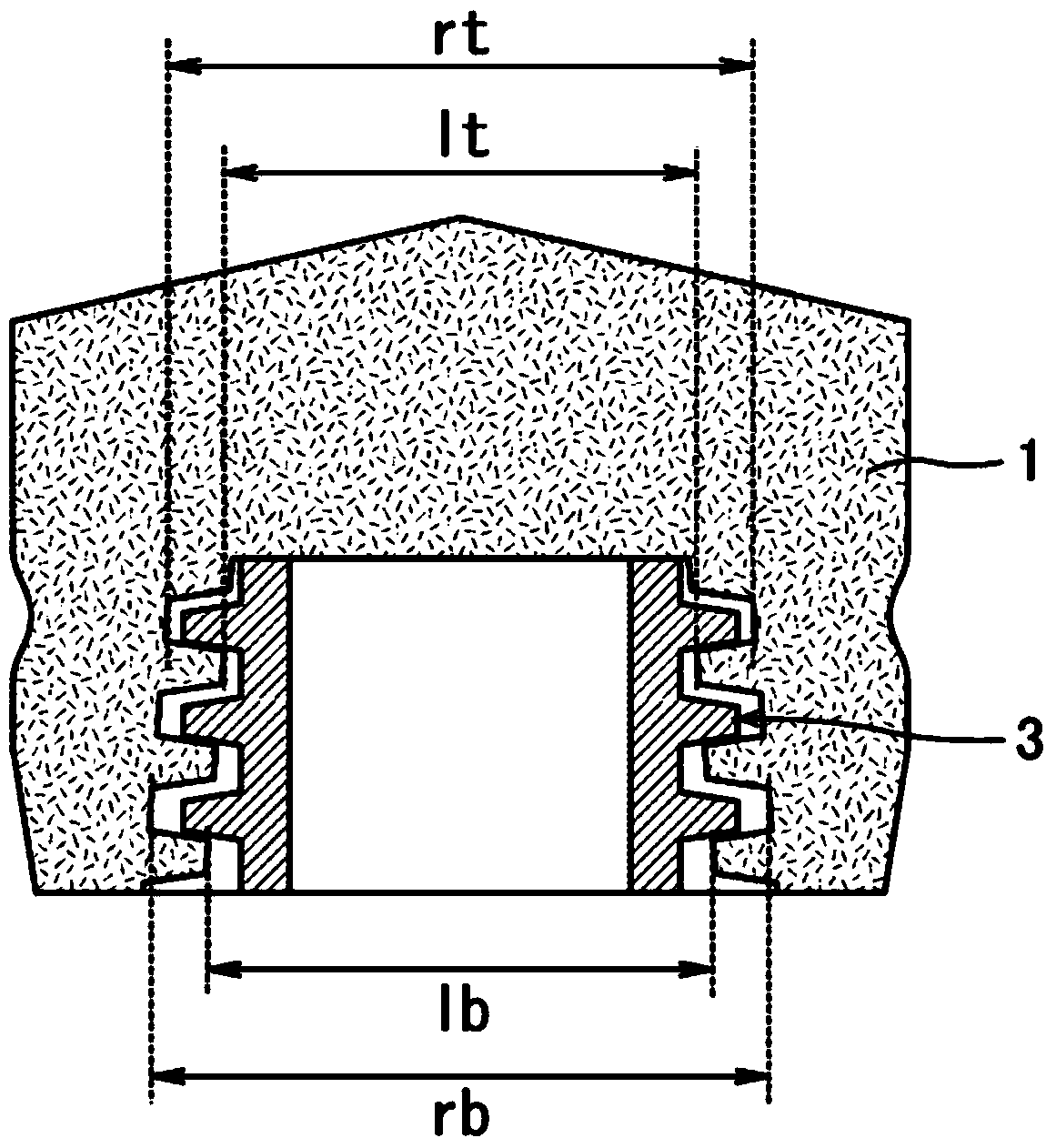

[0036] Gaskets of Examples in which the groove diameter of the female thread part of the gasket gradually increases from the side in contact with the chemical solution toward the opposite side of the gasket, and gaskets of Comparative Example in which the groove diameter is the same were produced. The unvulcanized rubber sheet was placed on a forming mold, and formed by vacuum pressing under the conditions of 180° C., 8 minutes, and a processing pressure of 20 MPa to make it vulcanized and bonded.

[0037] The outer diameter of the largest portion of the gasket was 20.0 mm, and Table 1 shows the groove diameter and thread diameter of the female thread portion of the obtained gasket. In addition, the length (depth) of the threaded portion was set to 7.0 mm, and the number of pitches was set to 17 pitches relative to 25.4 mm.

[0038]

[0039] Use a torque wrench (Tohnichi Seisakusho Co., Ltd., BTG60CN) to fit the plunger rod (made of polypropylene resin, the diameter of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com