Composite cooling device

A technology of heat dissipation device and heat dissipation unit, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problem of uneven heat dissipation of multiple LED chips, and achieve the effect of excellent heat transfer ability and good temperature uniformity and heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

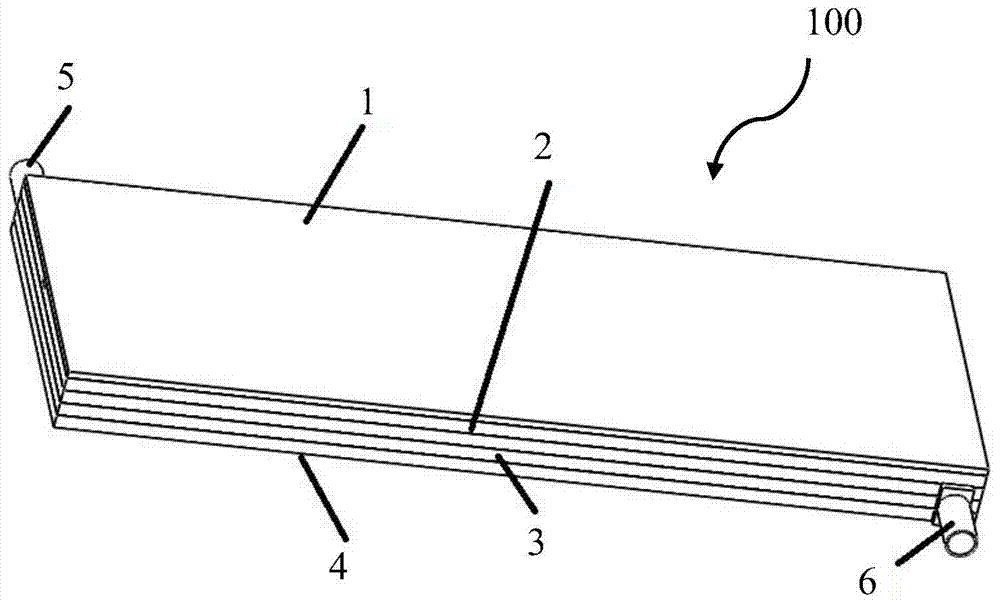

[0023] figure 1 It is a schematic diagram of the appearance structure of the composite heat sink in the embodiment.

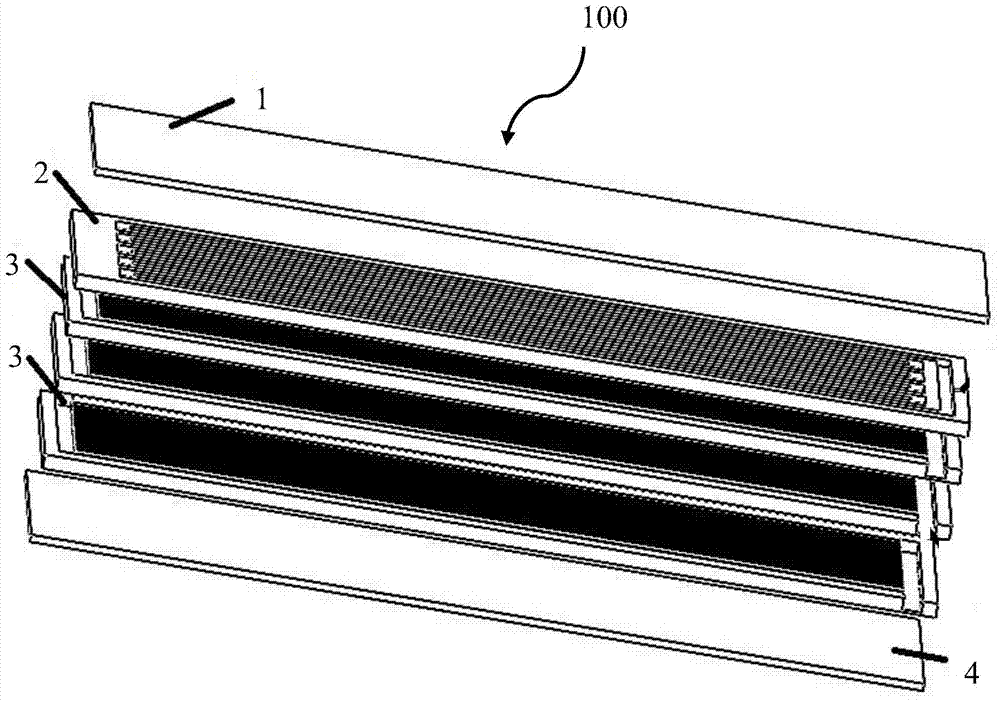

[0024] figure 2 It is a schematic diagram of the exploded structure of the composite heat sink in the embodiment.

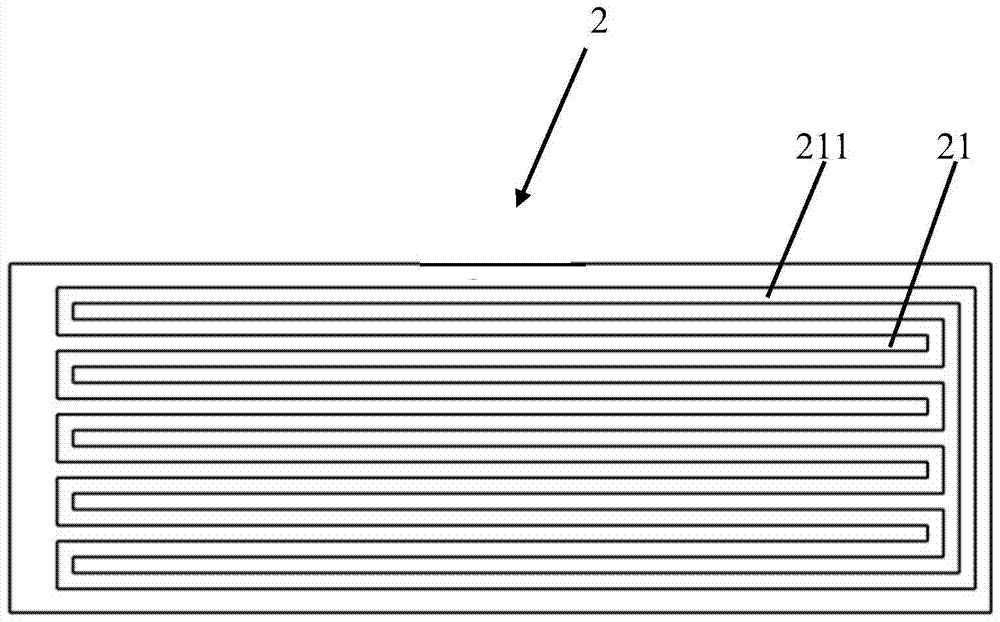

[0025] like figure 1 and figure 2 As shown, the composite heat dissipation device 100 includes a cover plate 1, a first heat dissipation unit 2, a second heat dissipation unit 3, a bottom plate 4, and a mass-incoming unit 5 and a mass-exiting unit 6 located on both sides of the second heat dissipation unit 3, the cover plate 1 and the The bottom plate 4 covers the upper end of the first heat dissipation unit 2 and the lower end of the second heat dissipation unit respectively, and the mass-incoming unit 5 and the mass-exiting unit 6 are all connected to the condenser outside the compound heat dissipatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com