A steel drum filling device that automatically discharges static electricity and a safe filling method

An automatic release and filling device technology, applied in the direction of static electricity, barrel/cask filling, electrical components, etc., can solve problems such as sparks, impacts, dangers, etc., and achieve health protection, safety factor, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

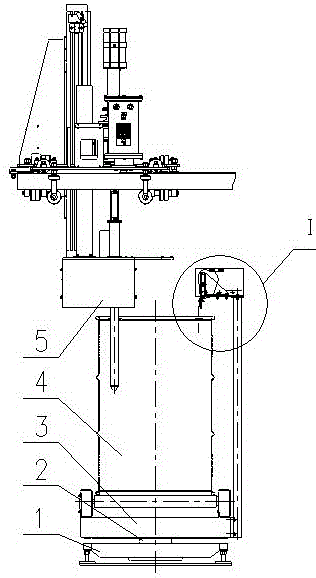

[0034] The present invention provides a steel drum filling device that automatically discharges static electricity and a safe filling method. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

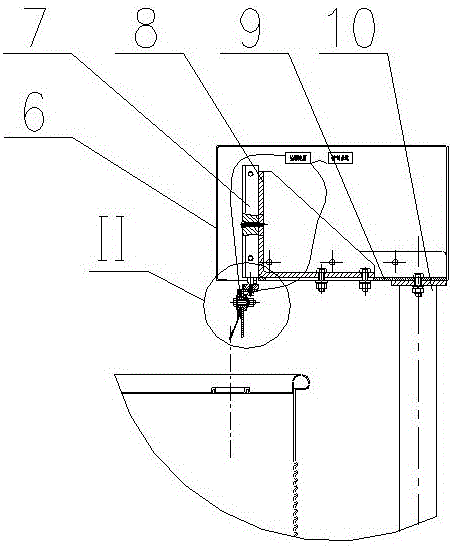

[0035] A steel drum filling device that automatically discharges static electricity, including: a charging structure, a weighing system, and a grounding structure; wherein, the grounding structure includes a cylinder 7, a contact and a fixing frame 10, and there are two contacts, namely, the contact I11 and the Contact II 15.

[0036] The grounding structure is connected to the weighing system through the fixed frame 10, and the cylinder 7 is fixed on the fixed frame 10 through the cylinder mounting seat 8. In order t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com