Deep-water contactless trigger switch

A non-contact, trigger switch technology, applied in the deep sea field, can solve the problems of low reliability, complicated production, long life, etc., and achieve the effect of safe and reliable work, compact structure and strong earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

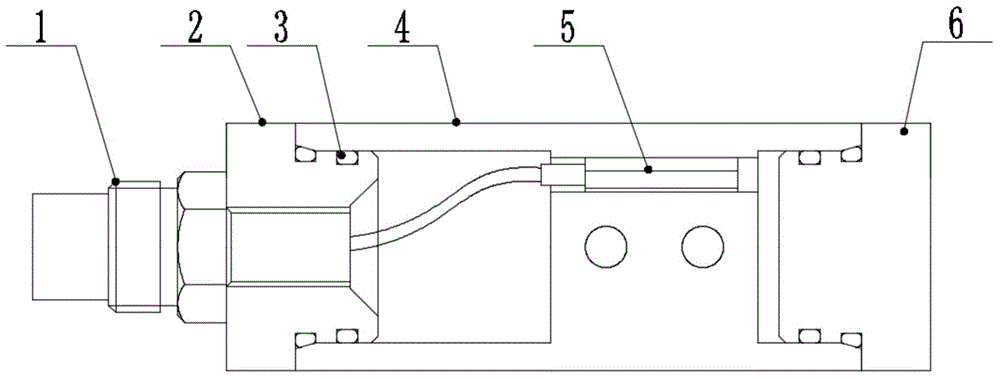

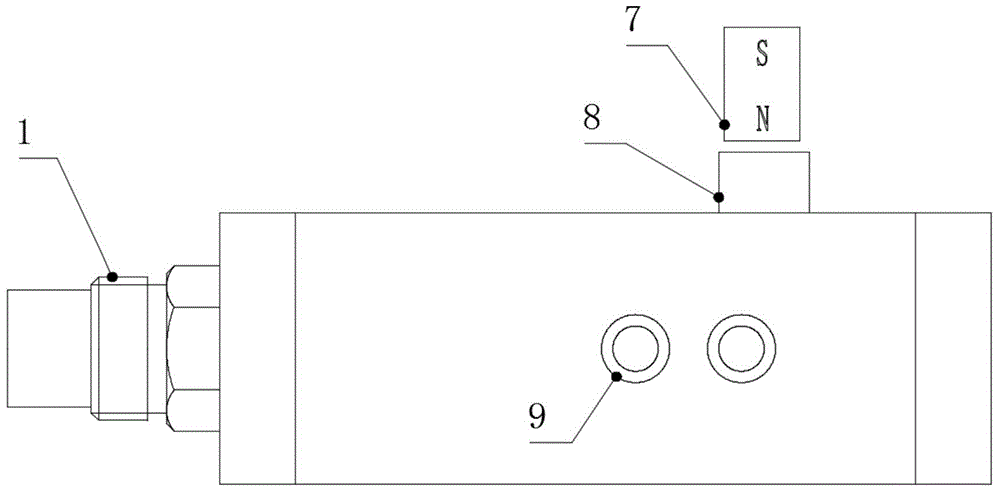

[0022] see figure 1 , this embodiment is a structural diagram of a deep-water non-contact trigger switch type I that can be used alone, including a small watertight connector 1, a front cover 2, an O-ring 3, a switch body 4, and a solid-state electronic non-contact switch element 5. The rear end cover 6; the solid-state electronic non-contact switch element 5 is sealed in the switch body 4, and the solid-state electronic non-contact switch element is equipped with a protection circuit; the front end of the switch body 4 cooperates with the front end cover 2, and the rear end of the switch body 4 Cooperating with the rear end cover 6, the O-ring 3 ensures its underwater tightness; the front end of the solid-state electronic non-contact switch element 5 is connected with the small watertight connector 1 through a connecting wire, which has strong shock resistance and shock resistance Sex, and is equipped with a protection circuit, even if it is reversed, it will not be damaged; ...

Embodiment 2

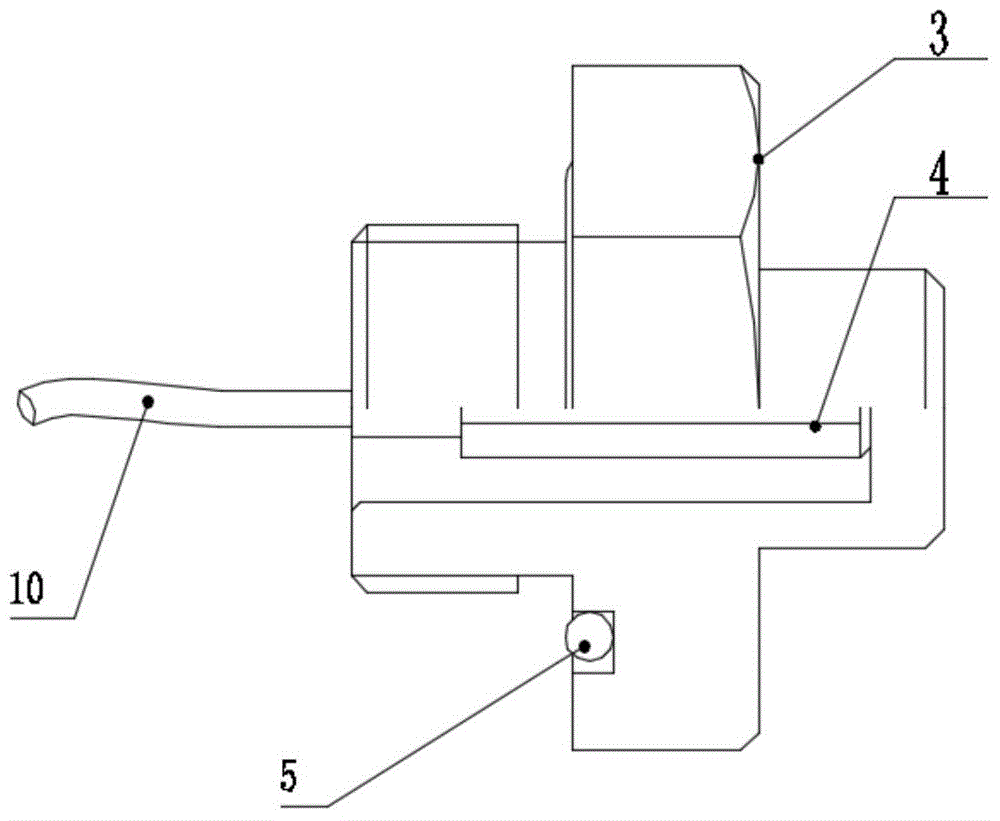

[0027] see image 3 , this embodiment is a variant of the deep-water non-contact trigger switch, that is, non-contact deep-water trigger switch type II, including an O-ring 3, a switch body 4, a solid-state electronic non-contact switch element 5, a lead wire 10, and a lead wire 10 Installed on the switch body 4, it can be directly connected with external components through the lead wire 10. Compared with the first embodiment, the type II non-contact deep-water trigger switch can be directly installed on the end cover of the deep-sea control pressure chamber without external cables, effectively solving the problem of compact structure of underwater instruments and equipment. Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com