Upper part electrode and manufacturing method of upper part electrode, and dry etching equipment

A technology of electrode and electrode body, which is applied in the direction of electrode system manufacturing, cold cathode manufacturing, discharge tube/lamp manufacturing, etc. It can solve the problems of short service life and poor workmanship of the upper electrode, achieve long service life, avoid poor workmanship, The effect of high temperature Mohs hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order for those skilled in the art to better understand the technical solution of the present invention, the upper electrode, its manufacturing method and dry etching equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

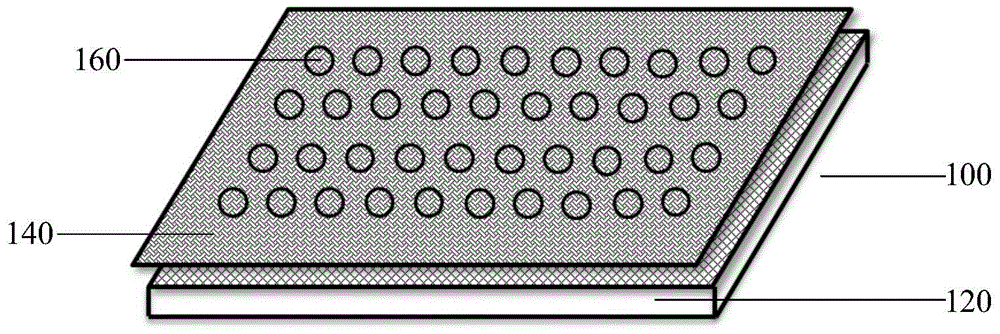

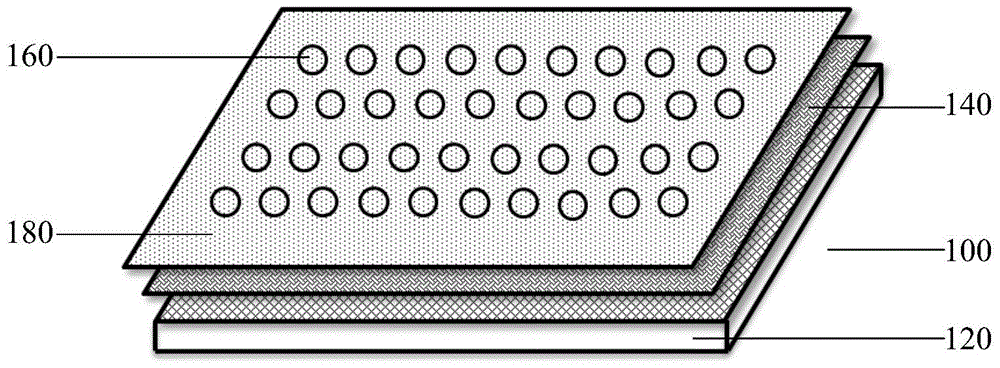

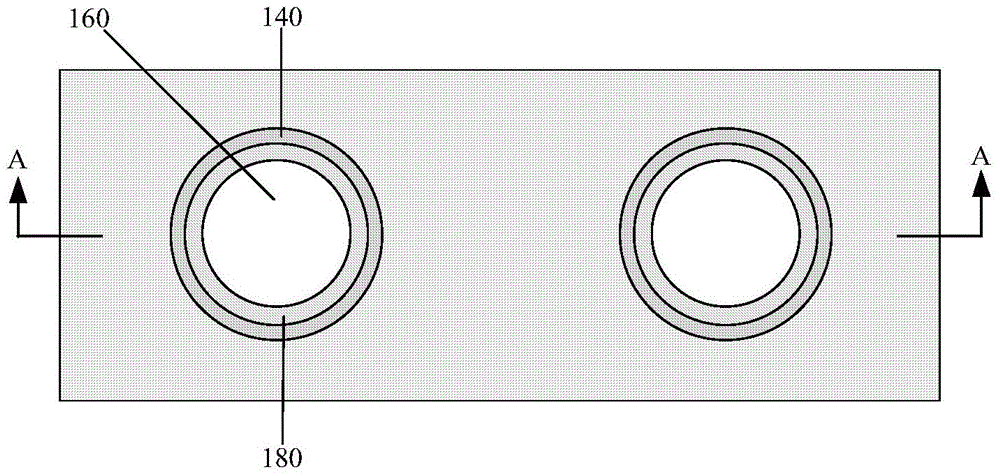

[0031] figure 2 It is a schematic structural diagram of an upper electrode provided in Embodiment 1 of the present invention. Such as figure 2 As shown, the upper electrode 100 includes an upper electrode body 120 on which an electrode gas outflow hole 160 is disposed. The surface of the upper electrode body 120 is covered with an ionic crystal layer 140. Preferably, the ionic crystal layer 140 is gamma-type aluminum oxide (γ-Al 2 o 3 )layer. The surface of the ionic crystal layer 140 is covered with an atomic crystal layer 180 . Preferably, the atomic crystal layer 180 is alpha alumina (α-Al 2 o 3 )layer.

[0032] It should be noted that: the electrode gas outflow hole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com