Service life evaluation method of ultra-supercritical boiler special steel pipe welding connector

A technology for ultra-supercritical boilers and welded joints, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as creep life and stress doubts, work stress sensitivity, creep damage failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

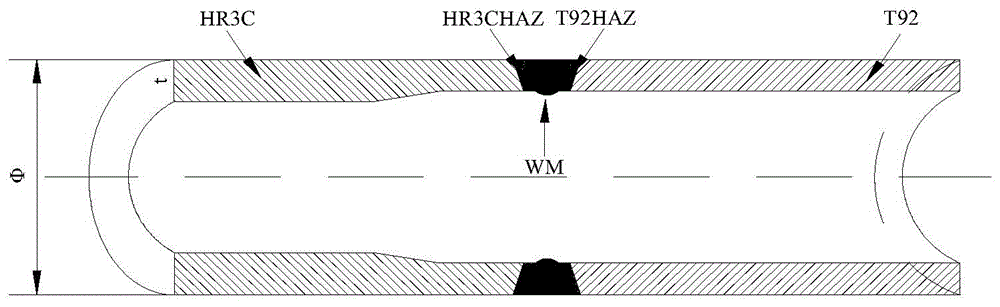

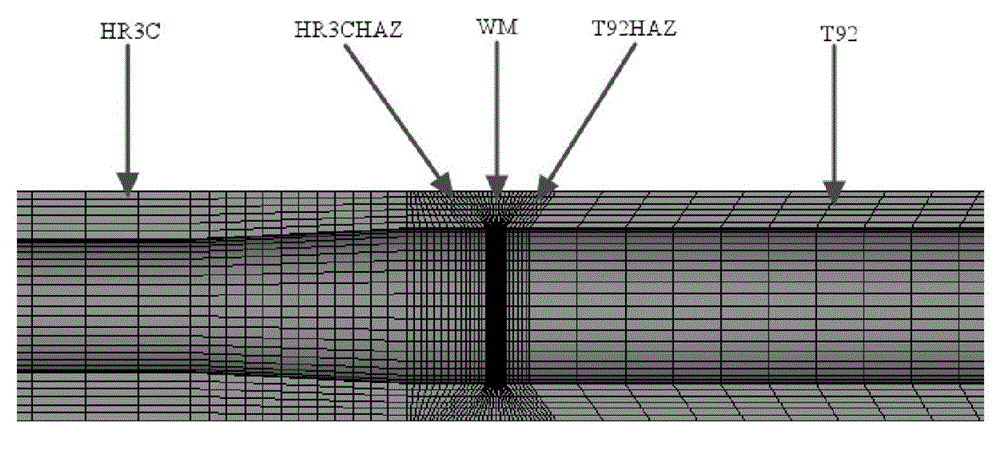

[0082] The present invention takes the weld zone (WM) in a T92 / HR3C dissimilar steel welded pipe of a 1000MW ultra-supercritical unit as a calculation example, the outlet steam parameter is 26.25MPa, 603°C / 605°C, and the pipe specification is (Φ×S / mm) 48.3×7.82.

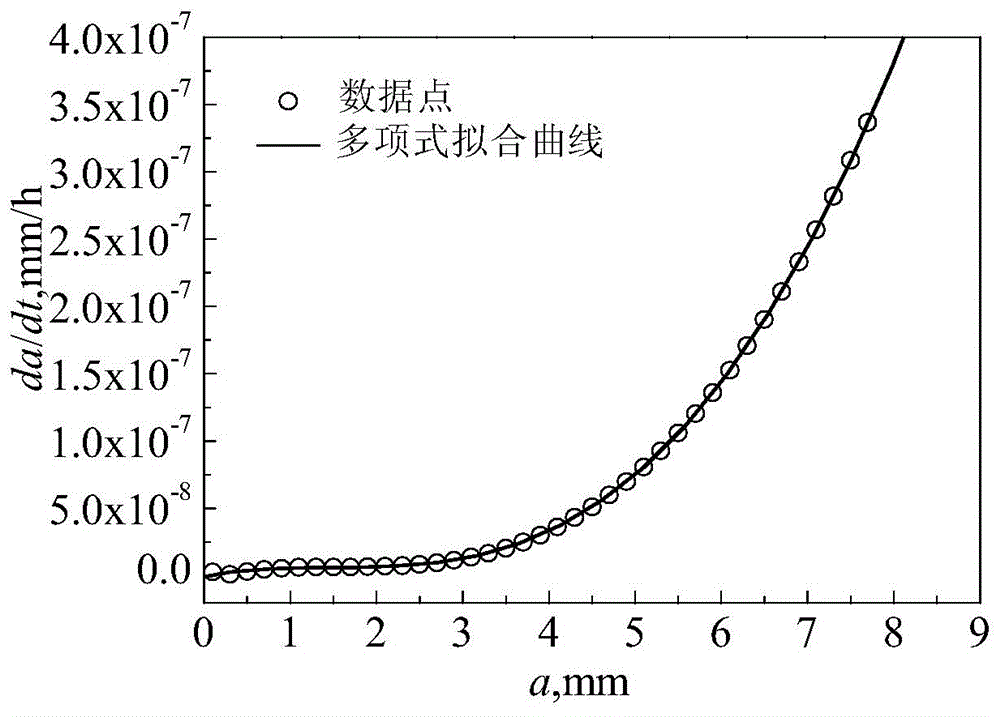

[0083] Since the welded joint pipe is very long along the axial length of the pipe, relative to the inner diameter of the pipe, the axial dimension is much larger than its pipe diameter, and the strain in the axial length direction can be ignored, so the problem can be simplified as a plane strain problem. Two-dimensional cracked pipe, as shown in Figure 1. The initial crack is located on the radially outer wall of the pipe, and the initial crack length is 0.1mm. When calculating, the internal pressure is 25MPa and the temperature is 600°C. The chemical composition of T92 / HR3C dissimilar steel welded pipe is shown in Table 1.

[0084] Table 1 Chemical composition of HR3C, T92, WM (wt%)

[0085]

[0086]

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com