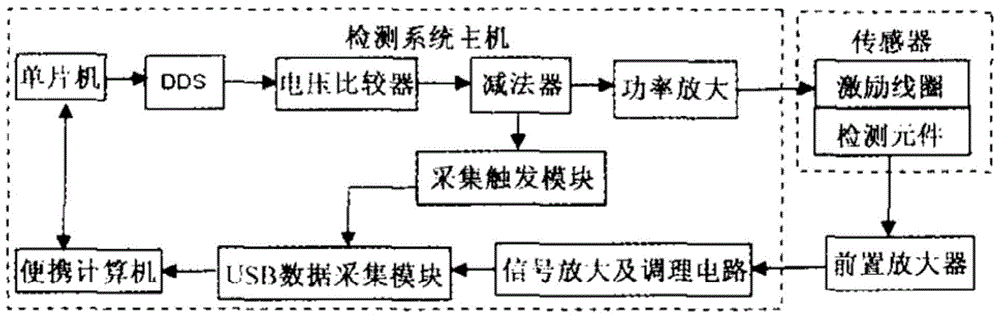

A pulsed eddy current electromagnetic nondestructive testing method based on a coil probe with iron core

A technology of iron core coil and pulsed eddy current, which is applied in the direction of electromagnetic measuring device, electric/magnetic thickness measurement, material magnetic variable, etc., can solve the problems such as the limitation of the detection ability of the hollow probe, the large distribution area of the pulsed magnetic field, and the weak detection signal, etc., to achieve Effects of fast attenuation, short diffusion time, and enhanced detection capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

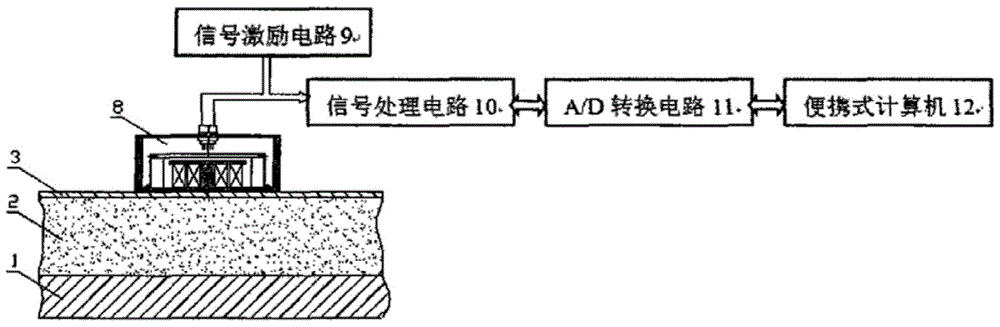

Examples

Embodiment 1

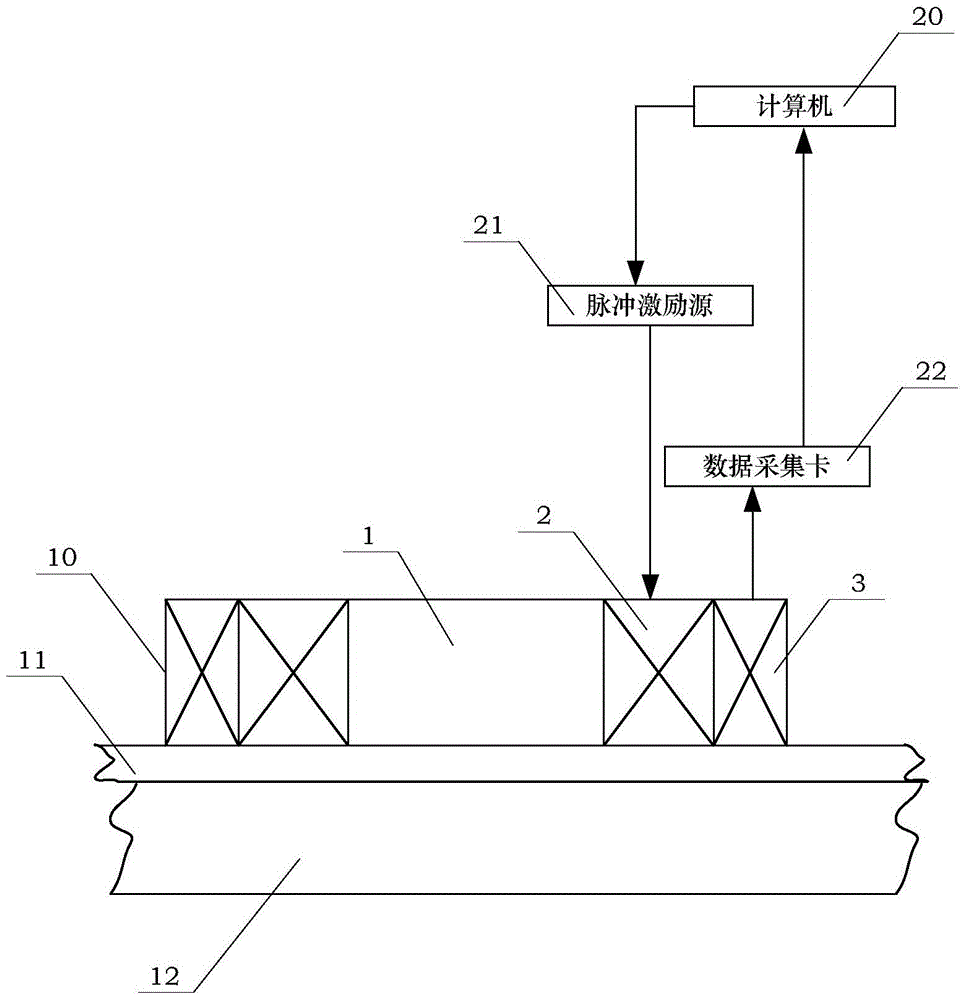

[0066] The following is an example of implementing pulsed eddy current detection on a steel pipe with a cladding layer by using a coil probe with an iron core in the present invention. The detection object is a 20# steel pipe with an outer diameter of 180.0mm and a wall thickness d of 11.0mm. The electrical conductivity σ of the steel pipe is 4MS / m, and the relative magnetic permeability μ r is 300, and the thickness of the outer cladding layer of the pipe is 40mm. Depend on The pulse eddy current diffusion time constant τ of the tested steel pipe can be calculated e = 18.5ms.

[0067] According to the test method of band iron core coil probe, measure the probe that the present invention designs in the air excitation current falling edge such as Figure 4 In the middle curve, the time constant τ of the probe is measured s = 0.28ms. Visible, there is Established, it shows that when using the coil probe with iron core designed by the present invention to implement pulsed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com