Flue gas sampling and mixing device

A mixing device and flue gas sampling technology, applied in sampling devices, preparation of test samples, etc., can solve problems such as uneven mixing, unrepresentative flue gas, and inability to accurately measure pollutant components and concentrations, and achieve the goal of promoting mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

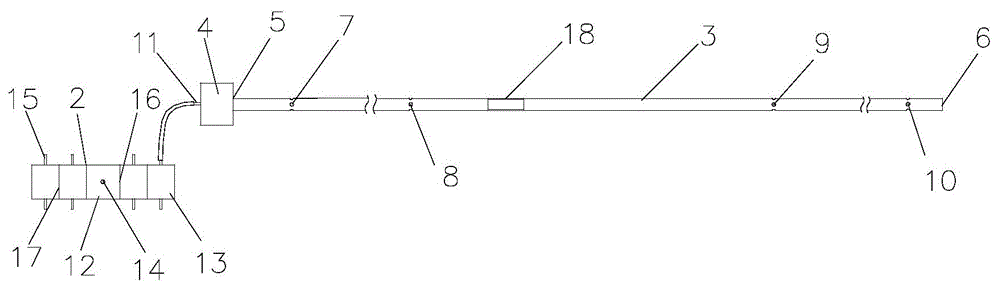

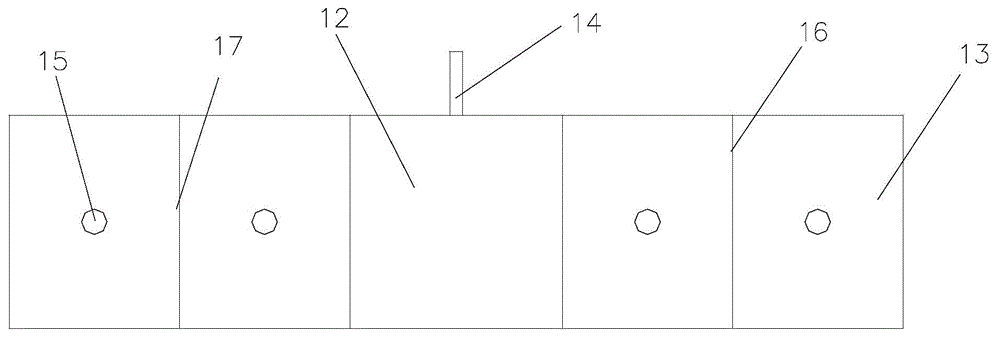

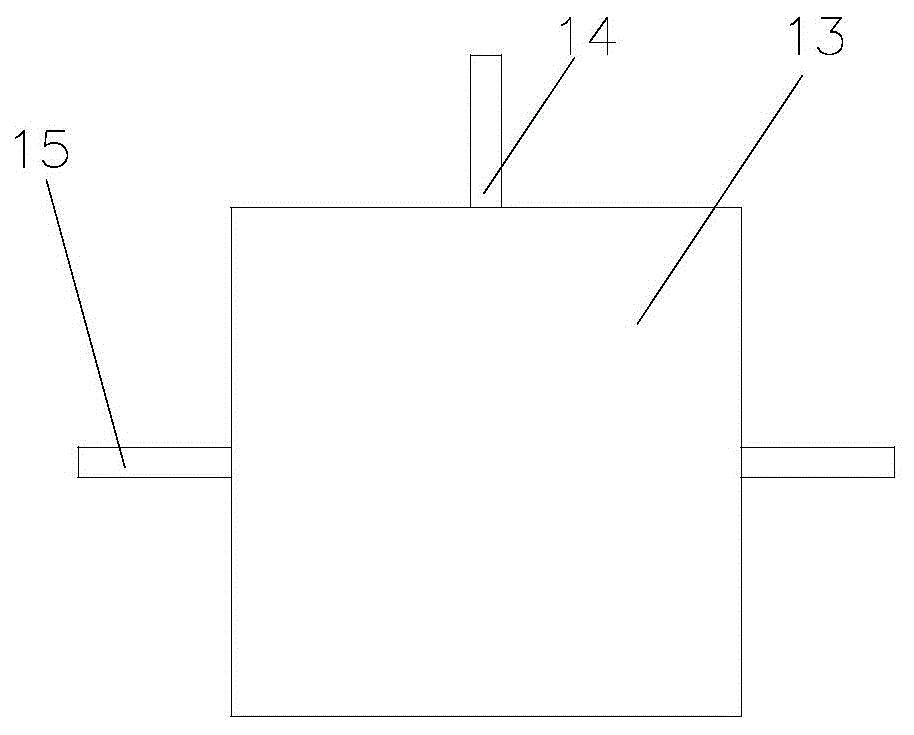

[0027] The smoke sampling and mixing device of the present invention will be described in detail below with reference to the accompanying drawings.

[0028] Such as figure 1 , 2, 6, a flue gas sampling and mixing device, including a sampling tube 1 and a flue gas mixer 2. The sampling tube 1 is composed of a sampling tube body 3 and a gas mixing tube 4 . The sampling tube 1 is a 304 stainless steel tube with a total length of 3.33m. The sampling tube body 3 has a length of 3.23m and a specification of 12*1mm. The length of the gas mixing tube is 0.1m and a specification of 32*1.5mm. One end of the sampling tube body 3 is an open end 5 , which communicates with the gas mixing tube 4 , and the other end is a sealing end 6 .

[0029] The sampling pipe body 3 is provided with sampling holes at intervals of 1m along the axial direction, and the sampling holes near the opening end 5 are set as the first-level sampling holes 7, and so on, and finally the sampling holes near the sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com