V type MEMS actuator for detonator protection device based on buckling amplification

A technology of buckling amplification and actuators, applied in fuzes, weapon accessories, offensive equipment, etc., can solve the problems of traditional fuzes such as large size and difficult integration, and achieve the effects of high intelligence, improved adaptability, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

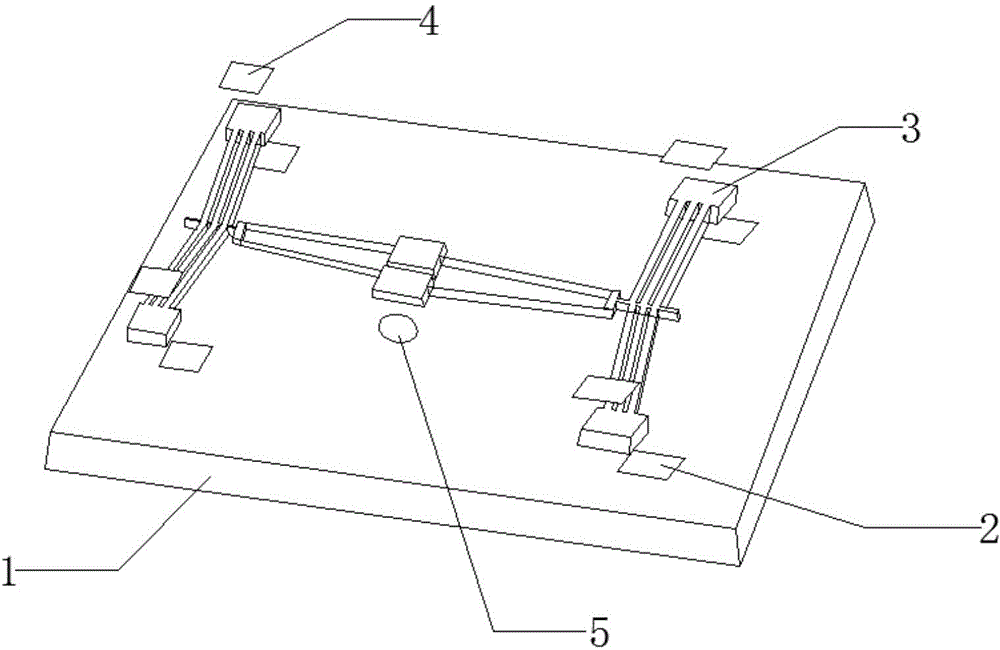

[0020] refer to figure 1 , a V-shaped MEMS actuator for a fuze security device based on buckling amplification, comprising a single crystal silicon substrate 1, an accelerating bore 5 with a diameter of 150-180um is fabricated on the single crystal silicon substrate 1, and the accelerating bore 5 It is the channel of the flyer material. The silicon dioxide insulating layer 2 is grown on the single crystal silicon substrate 1 with a growth thickness of 2-3um. The substrate 1 is bonded, the thickness of the monocrystalline silicon structural layer 3 is 50-100um, and the metal electrode layer 4 is deposited on the anchor point 3-2 of the monocrystalline silicon structural layer 3;

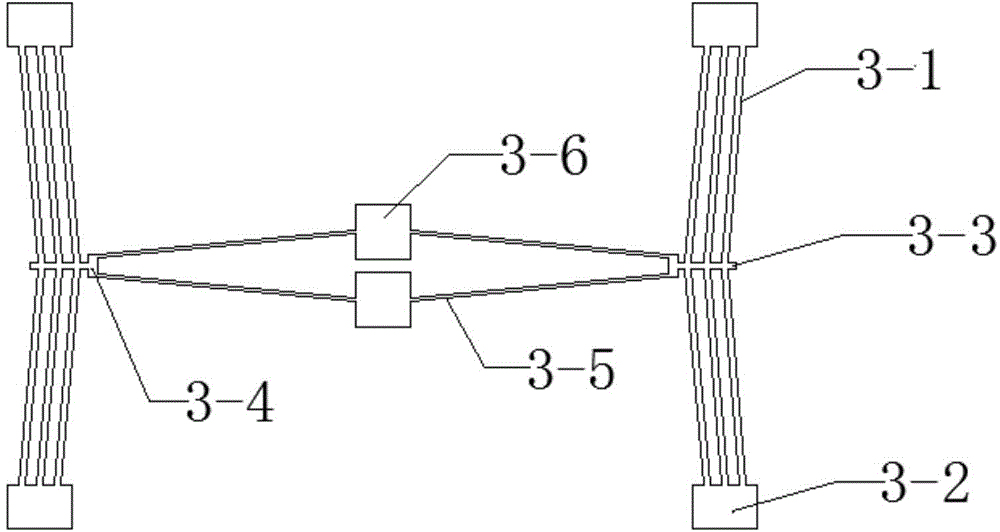

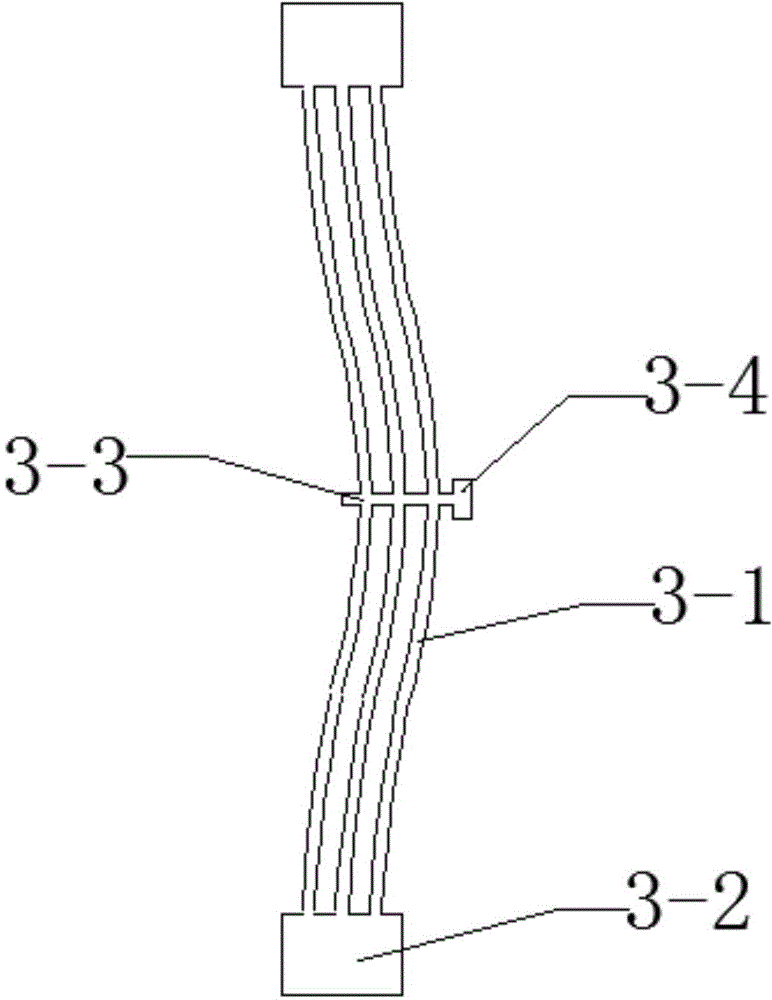

[0021] refer to figure 2 , the MEMS actuator is fabricated in the monocrystalline silicon structure layer 3, the MEMS actuator includes an anchor point 3-2, and the two ends of the V-beam t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com