Moisture-proof wood floor

A wood flooring and flooring technology, which is applied to tools used in roofing engineering, roofing, construction, etc., can solve the problems of no resistance, affecting the properties of the floor, and water infiltration, so as to achieve easy installation, avoid long-term water accumulation, reduce gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

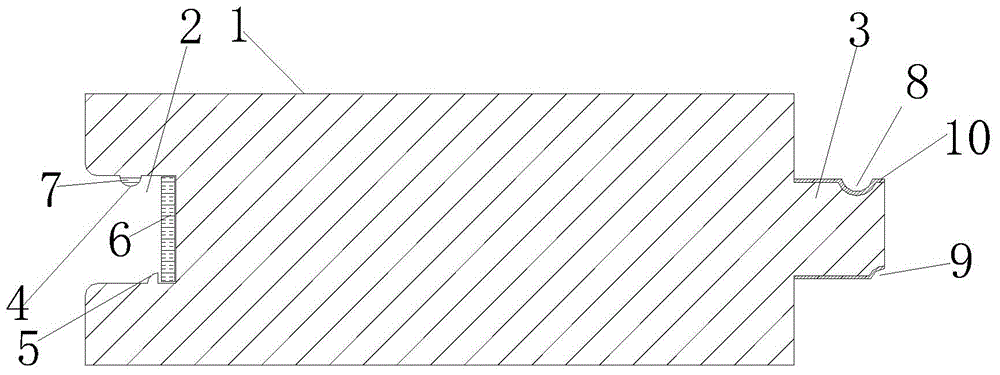

[0010] Example. A moisture-proof wooden floor such as figure 1 As shown, including the floor body 1, the two sides of the floor body 1 are respectively provided with a tongue groove 2 and a tongue 3, and the upper part of the tongue groove 2 is provided with a first rib 4 with a semicircular cross section, and the tongue groove 2 The lower part is provided with a second rib 5 with a quarter-circle cross section. The arc surface of the second rib 5 faces the opening direction of the tenon groove 2, and the second rib 5 is closer to the tenon than the first rib 4. The groove bottom of the groove 2, the groove bottom of the tongue groove 2 is provided with a water-swellable water-stop strip 6; the upper part of the tongue 3 is provided with a groove 8 corresponding to the shape and position of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com