Device and method for preparing ammonium persulphate with ammonia and urea solution flue gas purified absorption solution

An ammonium persulfate and flue gas purification technology, applied in the electrolysis process, electrodes, diaphragms, etc., can solve problems such as complex components, and achieve the effects of high separation efficiency, low energy consumption, and no secondary pollution emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

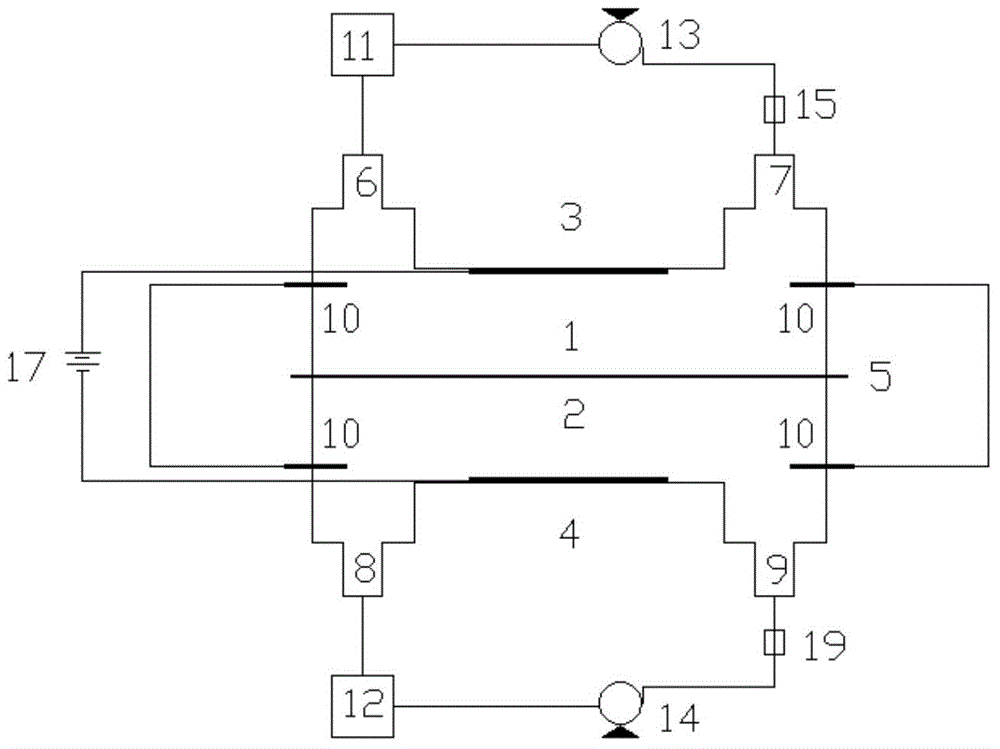

[0033]Embodiment 1: the device that ammonia and urea solution flue gas purification absorbing liquid of the present invention makes ammonium persulfate, comprises by being arranged on the plate type diaphragm 5, anode chamber 1 and cathode chamber 2 in the middle of the electrolytic cell body, is arranged in the anode chamber 1 There are an anode chamber outlet 6 and an anode chamber inlet 7, a titanium platinum-plated anode plate 3 is arranged on the inner wall, a cathode chamber outlet 8 and a cathode chamber inlet 9 are arranged in the cathode chamber 2, a titanium cathode plate 4 is arranged on the inner wall, and the anode chamber inlet 7 is connected with an anolyte liquid supply pump 16 and an anode flowmeter 18, the flow at the inlet of the anode chamber is controlled by the anolyte liquid supply pump 16 and the anode flowmeter 18, and the cathode chamber inlet 9 is connected with a catholyte liquid supply pump 17 and a cathode flowmeter 19. The inlet flow rate of the a...

Embodiment 2

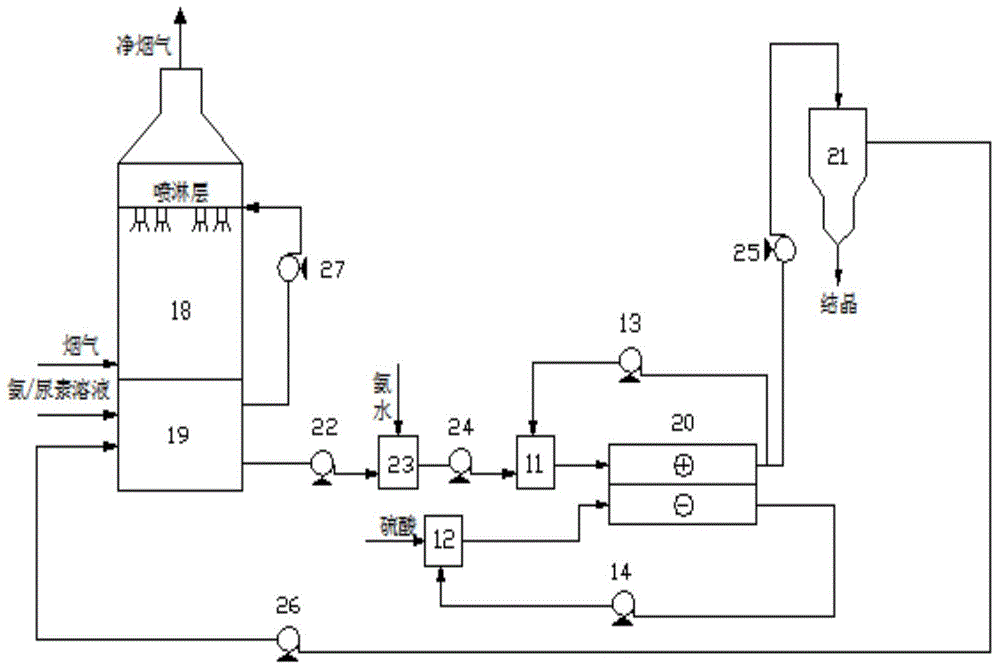

[0035] Embodiment 2: pump the absorption liquid in the absorption liquid storage tank 19 at the bottom of the desulfurization and denitrification absorption tower 18 into the neutralization reactor 23 through the neutralization pump 22 of the desulfurization and denitrification circulating liquid, and neutralize the liquid of the circulating liquid by adding a certain amount of ammonia water. The pH is adjusted between 4-6, and the neutralized solution (the concentration of ammonium sulfate in the solution is 328g / L, the mass concentration of ammonium sulfite is 56g / L, and the mass concentration of ammonium nitrate is 12g / L, the mass concentration of ammonium nitrite is 4.3g / L, the mass concentration of urea is 1.15g / L, the mass percentage concentration of diethanolamine and triethanolamine is 0.015%, the anode oxygen suppression additive ammonium thiocyanate (or polyphosphoric acid Ammonium) accounts for 0.01% mass percentage concentration of the absorption liquid obtained by ...

Embodiment 3

[0036] In embodiment 3, the mass percentage concentration of the sulfuric acid solution pumped into the cathode chamber 2 is 40%, and the oxygen inhibitor pumped into the anode chamber 1 accounts for the mass percentage concentration of the absorption liquid obtained by the ammonia and urea solution flue gas purification process is 0.055%. The basic process and other parameters are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com