Ultra-high-strength fastening connecting piece and manufacturing method thereof

A technology for fastening connectors and ultra-high strength, applied in the field of metal materials, can solve problems such as hydrogen embrittlement, low strength, loss of plasticity, etc., and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

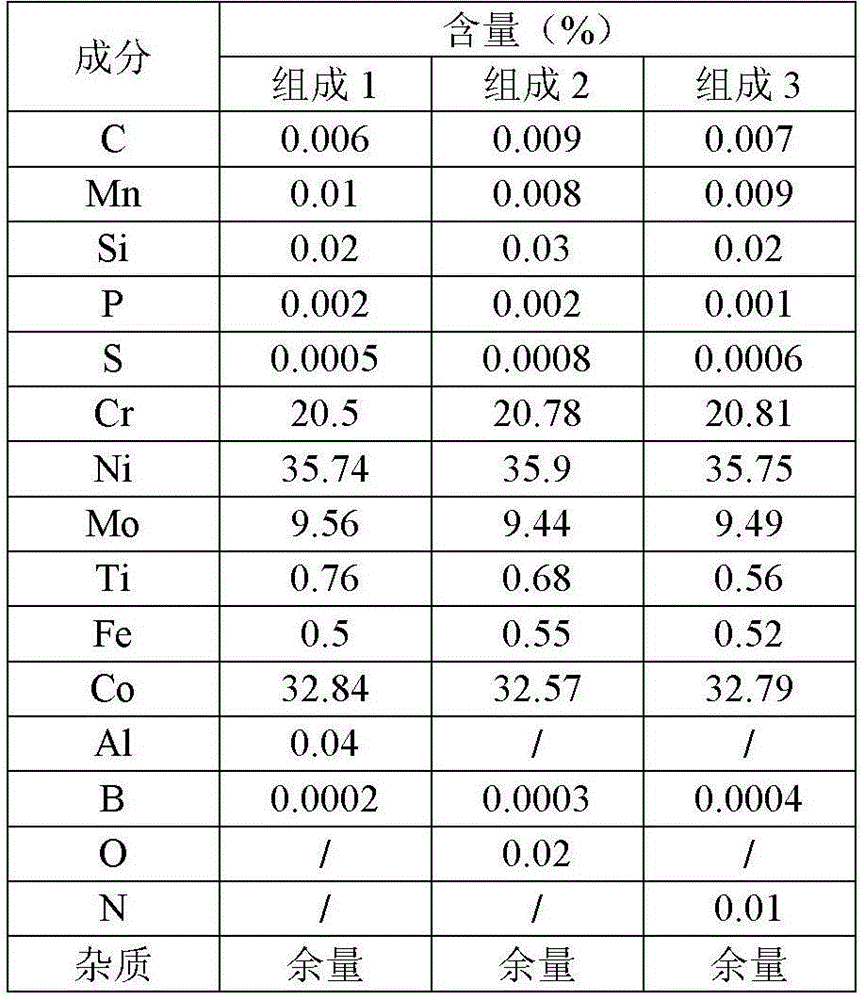

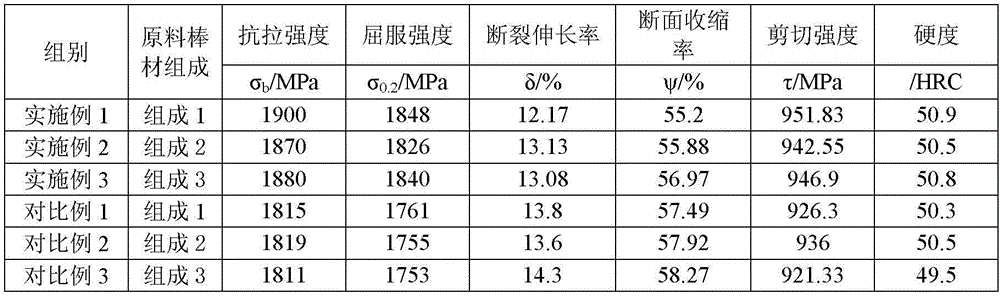

[0019] The raw material rods with component contents of composition 1, composition 2 and composition 3 in Table 1 were solid-dissolved at 1040°C for 4h, and air-cooled; cold drawing was carried out to reduce the cross-sectional area by 50%; material cutting and rough processing Afterwards, aging at 600°C×4h, air cooling; the head is upsetting, and the thread is further processed by rolling forming to obtain the final product of ultra-high-strength fastening connectors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com