Method for preparing poly-alpha-alkene synthetic oil from coal-based raw materials

A technology for synthesizing oil and raw materials from olefins, applied in the production of liquid hydrocarbon mixtures, the petroleum industry, etc., can solve the problems of high prices and low viscosity index, achieve the effect of wide sources and break through the relationship between supply and demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

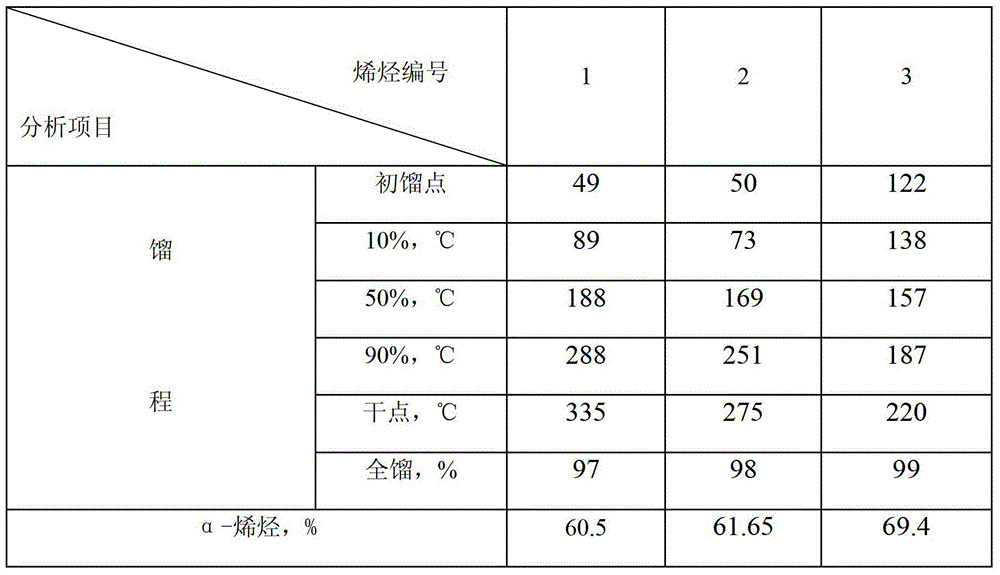

Embodiment 1

[0031] In a 1L reactor equipped with a stirrer and a thermometer, add 600 g of α-olefins (1# olefins in Table-1) separated by real boiling point distillation, and add AlCl 3 24g of catalyst, start stirring, react at 130°C for 2 hours, cool down to 80°C, let stand for 24 hours, remove catalyst residue. Transfer the deslagging polymer into a reactor equipped with a stirrer, a thermometer, and a condenser, add 120g of calcium hydroxide and 180g of activated clay, raise the temperature to 150°C, keep at this temperature for 1 hour, and refine it with clay , lower the temperature to below 80°C, remove the solid residue by filtration, pass the obtained sample through a small hydrogenation device, in the presence of a nickel-based catalyst, the reaction pressure is 2.0MPa, the reaction temperature is 180°C, the polymer is mixed with hydrogen for hydrogenation refining, and the product is separated Finally, polyalphaolefin synthetic oil is obtained.

Embodiment 2

[0033] The operation steps are the same as Example 1, using 2# olefin in Table-1.

Embodiment 3

[0035] The operation steps are the same as Example 1, using 3# olefin in Table-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com