Dehydrating method for organic solvent

A technology of organic solvents and water-organic solvents, applied in the field of dehydration of organic solvents, can solve problems affecting product quality and exceeding standards, and achieve low cost, simple operation and wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

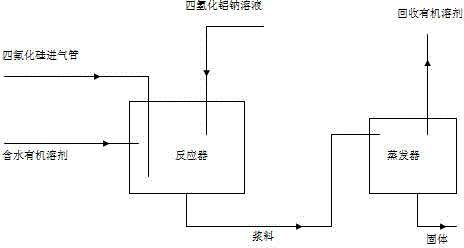

Method used

Image

Examples

example 1

[0041] Add 2000kg of ethylene glycol dimethyl ether containing 5% water into the reactor with agitator and condenser, slowly add 1100kg of 15% sodium aluminum tetrahydride solution, stir well and control the reaction temperature at about 40°C, Continue to react for 2 hours; feed 150kg of 95% silicon tetrafluoride gas, and continue to react for 1 hour; the slurry is delivered to a thin film evaporator, and the organic solvent is recovered to obtain 2650kg of ethylene glycol dimethyl ether, which contains The amount of water was 287ppm.

example 2

[0043] Add 3000kg of toluene and ethylene glycol dimethyl ether mixed solvent containing 1.5% water into the reactor with stirrer and condenser, slowly add 550kg of 13% sodium aluminum hydride solution, fully stir and control the reaction temperature at At about 40°C, continue to react for 5 hours; feed 30kg of 95% silicon tetrafluoride gas, and continue to react for 1 hour; transport the slurry to a thin film evaporator, recover the organic solvent in it, and obtain 3400kg of mixed solvent. After analysis, it contains The amount of water is 232ppm.

example 3

[0045] Add 1000kg of toluene with 3.5% water content into the reactor with agitator and condenser, slowly add 400kg of sodium aluminum tetrahydride solution containing 14%, stir well and control the reaction temperature at about 40°C, and continue the reaction for 5 hours; Introduce 25kg of 95% silicon tetrafluoride gas, and continue to react for 8 hours; transport the slurry to a vacuum evaporator, recover the organic solvent therein, and obtain 950kg of toluene and 330kg of ethylene glycol dimethyl ether. After analysis, the water contents were 189ppm and 248ppm respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com