High-activity seaweed fertilizer specially used for peanut and preparation method thereof

A high-activity, seaweed fertilizer technology, applied in the direction of alkaline orthophosphate fertilizer, fertilizer made from biological waste, etc., can solve the problem that the single application of potassium fertilizer has no obvious effect on increasing production, and achieve the improvement of synthesis rate and carbon accumulation , Peanut plants are strong, and the effect of improving the activity of enzymes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

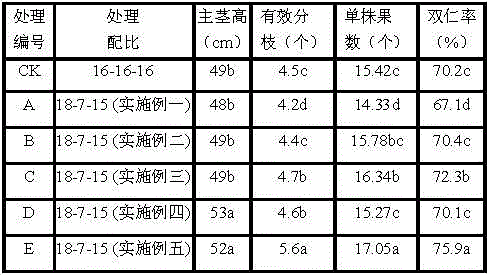

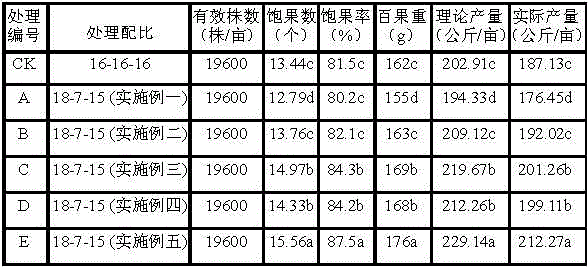

Examples

Embodiment 1

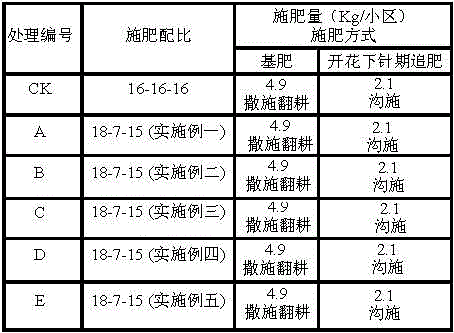

[0045] Raw material ratio: 360 parts of urea, 145 parts of monoammonium phosphate, and 300 parts of potassium sulfate.

[0046] The specific production process is as follows:

[0047] 1. Measure urea, monoammonium phosphate, and potassium sulfate according to the ratio and then fully stir and mix them in the stirring pot;

[0048] 2. After the above materials are mixed evenly, they are conveyed into the granulator by a belt. A nozzle is installed in front of the granulator to spray steam to make the materials into balls and granulate. The granulation temperature is controlled at 40°C-50°C;

[0049] 3. The preliminary pelletized material enters the first drying drum and the first cooling drum in turn, and the temperature of the first drying outlet is controlled at 60°C-70°C;

[0050] 4. After the first cooling drum is discharged, the material is screened, and the large particles screened out are crushed and put into the granulator for granulation; the semi-finished products ob...

Embodiment 2

[0054] Raw material ratio: 365 parts of urea, 120 parts of monoammonium phosphate, 65 parts of calcium magnesium phosphate fertilizer, 300 parts of potassium sulfate, 15 parts of borax, 8 parts of EDTA chelated iron, 6 parts of EDTA chelated manganese, 7 parts of EDTA chelated zinc, 1 part of ammonium heptamolybdate.

[0055] Concrete production technology is with embodiment 1.

[0056] The obtained product has the specifications of 18-7-15, contains medium and trace elements, and does not contain seaweed extract and seaweed residue.

Embodiment 3

[0058] Raw material ratio: 365 parts of urea, 120 parts of monoammonium phosphate, 65 parts of calcium magnesium phosphate fertilizer, 300 parts of potassium sulfate, 15 parts of borax, 8 parts of EDTA chelated iron, 6 parts of EDTA chelated manganese, 7 parts of EDTA chelated zinc, 1 part of ammonium heptamolybdate, 10 parts of seaweed extract (note: 50 parts of liquid, namely 10 parts of dry basis).

[0059] Concrete production process is the same as embodiment 1 except step 2.

[0060] Step 2: After the above materials are mixed evenly, they are conveyed into the granulator by a belt. Two nozzles are installed at the front of the granulator, one of which sprays a certain amount of seaweed extract calculated according to the proportion, and the other nozzle sprays steam to make the material into a granulator. Ball granulation, the granulation temperature is controlled at 40°C-50°C.

[0061] The obtained product has the specification of 18-7-15, contains medium and trace ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com