A Method for Reinforcement of Magnesite Feldspar Bone Scaffold with Nano-TiO in Selected Area Laser Sintering

A technology of selective laser sintering and nano-titanium dioxide, which is applied in the field of bone tissue engineering to achieve the effects of improving sintering performance, good biocompatibility, and promoting proliferation and differentiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with an embodiment, but the content of the present invention is not limited thereto:

[0022] (1) Use an electronic balance to accurately weigh nano-TiO with a mass of 0.25g 2 powder and 4.75g of micron AK powder, the two powders are mixed evenly by mechanical mixing, and finally TiO 2 AK / TiO with a mass fraction of 5% 2 Composite powder.

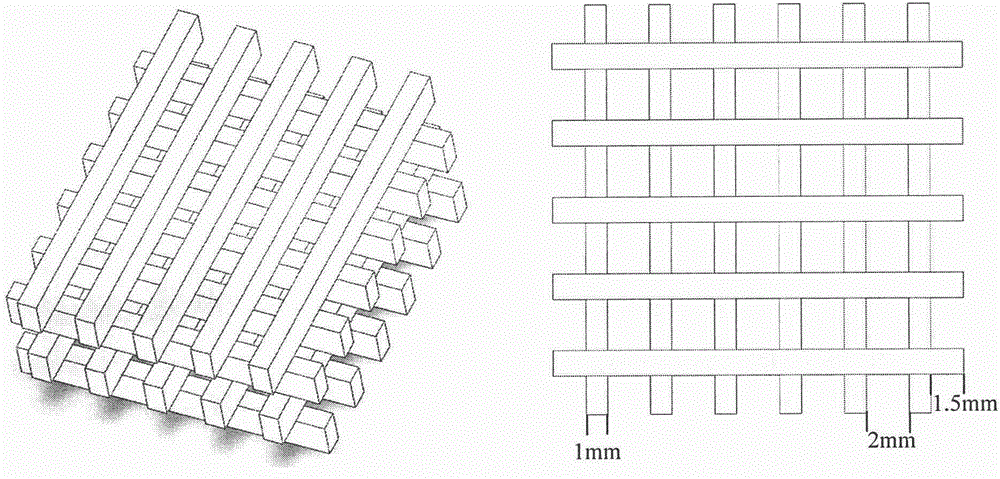

[0023] (2) First, use the SolidWorks 3D design software to design the structure of the porous scaffold. The designed 3D porous scaffold is shown in the attached figure 1 As shown in Fig. 1, the designed 3D data model is imported into the computer for layered slice processing to obtain the cross-sectional profile information of each layer. Then, put the prepared substrate on the working platform, evenly spread a thin layer of mixed powder on the substrate, the thickness of the powder coating is 0.1-0.2μm, and the laser starts to move alo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com