Integrated non-gradient activated sludge sewage treatment device

A sewage treatment device and activated sludge technology, applied in the direction of aerobic process treatment, sustainable biological treatment, etc., can solve the problems of inability to deal with high-concentration organic wastewater, cannot achieve high treatment load, and reduce system treatment effect, etc., to achieve The effect of increasing sewage treatment load, improving treatment efficiency, and enhancing mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

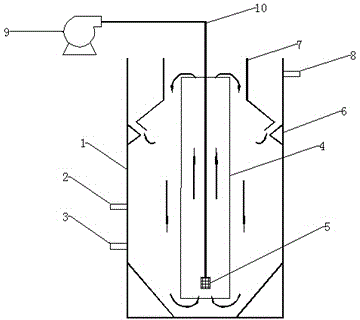

[0027] ginseng figure 1 As shown, the integrated non-gradient activated sludge sewage treatment device includes a reactor shell 1, the reactor shell 1 is cylindrical, and has a cylindrical accommodation space with an open top.

[0028] The reactor shell 1 is provided with a water inlet 2 , a sludge discharge port 3 and a water outlet 8 respectively communicating with the containing space, wherein the sludge discharge port 3 is located at the bottom, and the water outlet 8 is located at the top.

[0029] The bottom of the reactor shell 1 is provided with an inverted conical frustum. A lifting cylinder 4 coaxially arranged with the reactor shell 1 is arranged in the accommodation space. The lifting cylinder 4 is cylindrical, and the lifting cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com