Integrated coarse salt refining machine set

An integrated, crude salt technology, applied in the direction of alkali metal halide purification, etc., can solve the problems of slow reaction efficiency, low purity, secondary pollution, etc., and achieve the effect of simple structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

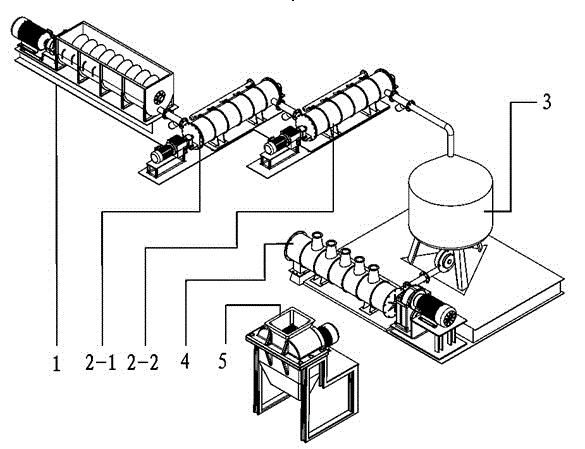

[0010] The present invention will be further described with reference to the accompanying drawings.

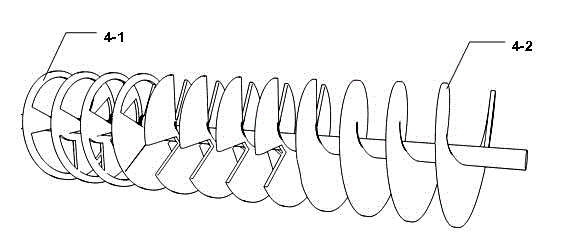

[0011] The spiral salt washer 1 is connected with the first mixing agitator 2-1, and is also connected with the evaporator 4 through a pipeline, so that the fresh water collected by the evaporator 4 can be used in the spiral salt washer 1 to achieve circulation Use water resources. The spiral salt washing machine 1 includes a heating device, and its box body is an interlayer, and hot water or other heat-conducting fluid medium is passed through the interlayer, which can quickly dissolve the solid coarse salt; the first mixing agitator 2-1 mixes with the second The agitator 2-2 is connected, the second mixing agitator is connected with the tank body 3, the tank body 3 is connected with the evaporator 4, and the spiral material guide wheel in the evaporator 4 includes two sections: the section close to the tank body 3 is hollowed out Section 4-1, in order to better increase the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com