A method for converting Fischer-Tropsch synthesis tail gas into Fischer-Tropsch synthesis feed gas

A technology of Fischer-Tropsch synthesis and raw material gas, applied in chemical instruments and methods, inorganic chemistry, chemical industry, etc., can solve the problems of high purity control requirements, and achieve the effect of simple process, convenient operation and full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

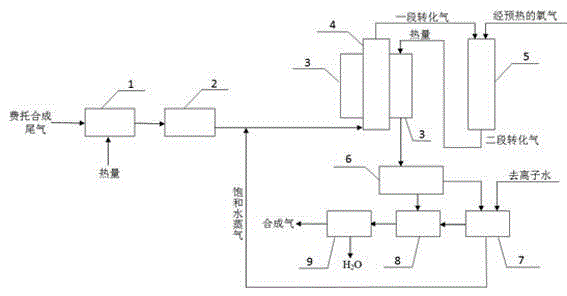

Method used

Image

Examples

Embodiment 1

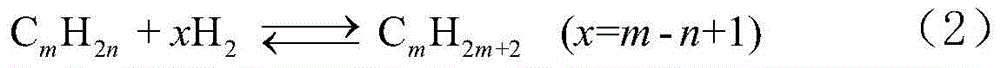

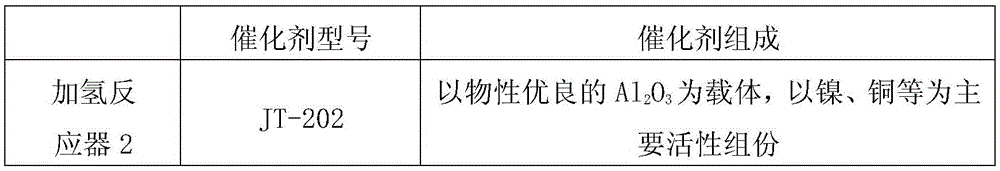

[0074] (1) 40°C, 2.4MPa, space velocity is 1500h -1 Fischer-Tropsch synthesis tail gas (its main components are 16.4% CO, 40.3% H 2 , 40.2%CH 4 , 1.2% low carbon hydrocarbons, 0.1% CO 2 , 1.83%N 2 ) is preheated to 200°C and enters the hydrogenation reactor 2, under the action of the catalyst JT-202 at 230°C, 2.4MPa, and a space velocity of 1500h -1 Under the conditions of hydrogenation reaction, C 2 h 4 and C 3 h 6 All converted to C 2 h 6 and C 3 h 8 , the gas after hydrogenation is mixed with saturated steam at 230°C and 2.4MPa according to the water-to-carbon ratio of 3.0, and then heated to 500°C to enter the primary reformer 4;

[0075] (2) The mixed gas entering the primary reformer 4 is in the presence of catalysts Z112-HA and Z112-HB at a weight ratio of 1:1, the operating temperature is 720°C, the pressure is 2.4MPa, and the space velocity is 1500h -1, and part of the heat provided by the high-temperature reformed gas from the secondary reformer 5 to the ...

Embodiment 2

[0079] (1) 40°C, 2.5MPa, space velocity is 1200h -1 Fischer-Tropsch synthesis tail gas (its main components are 16.4% CO, 40.3% H 2 , 40.2%CH 4 , 1.2% low carbon hydrocarbons, 0.1% CO 2 , 1.83%N 2 ) is preheated to 220°C and enters the hydrogenation reactor 2, under the action of the catalyst JT-202 at 220°C, 2.5MPa, and a space velocity of 1100h -1 Under the conditions of hydrogenation reaction, C 2 h 4 and C 3 h 6 All converted to C 2 h 6 and C 3 h 8 , the gas after hydrogenation is mixed with saturated steam at 230°C and 2.5MPa according to the water-to-carbon ratio of 2.9, and then heated to 500°C to enter the primary reformer 4;

[0080] (2) The mixed gas entering the primary reformer 4 is in the presence of catalysts Z112-HA and Z112-HB at a weight ratio of 0.9:1.1, the operating temperature is 740°C, the pressure is 2.5MPa, and the space velocity is 1100h -1 , and part of the heat provided by the high-temperature reformed gas from the secondary reformer 5 to...

Embodiment 3

[0083] (1) 40°C, 2.3MPa, space velocity 1000h -1 Fischer-Tropsch synthesis tail gas (its main components are 16.4% CO, 40.3% H 2 , 40.2%CH 4 , 1.2% low carbon hydrocarbons, 0.1% CO 2 , 1.83%N 2 ) is preheated to 240°C and enters the hydrogenation reactor 2, under the action of the catalyst JT-202 at 230°C, 2.3MPa, and a space velocity of 1200h -1 Under the conditions of hydrogenation reaction, C 2 h 4 and C 3 h 6 All converted to C 2 h 6 and C 3 h 8 , the gas after hydrogenation is mixed with saturated steam at 230°C and 2.3MPa according to the water-to-carbon ratio of 2.7, and then heated to 500°C to enter the primary reformer 4;

[0084] (2) The mixed gas entering the primary reformer 4 is in the presence of the catalyst Z112-HA and Z112-HB with a weight ratio of 0.8:1, the operating temperature is 800°C, the operating pressure is 2.3MPa, and the space velocity is 1200h -1 , and part of the heat provided by the high-temperature reformed gas from the secondary ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com